If you take a walk around the neighborhood, the odds are you’ll see aerial cables. Usually, these hang from poles, or installers place them on buildings. And their main advantages include fast completion time, suitability for rocky terrains, and cost savings.Are you thinking about installing aerial fiber optic cables? If yes, you’ve come to the right place. Now, check out the essentials below, and get ready for your project!

Table of Contents

- What Is an Aerial Fiber Optic Cable?

- What Are the Main Types of Aerial Fiber Optic Cables?

- How to Improve Speed and Efficiency of Aerial Fiber Deployment

- Conclusion

What Is an Aerial Fiber Optic Cable?

Caption: A fiber optic cable on the pole

Aerial fiber belongs to the class of the optic cables you install on a pole. Therefore, you use these products in outdoor environments. The word “aerial” comes from the fact you place them on certain heights.

You’ll often find aerial fibers in secondary trunk levels and below them. Furthermore, you usually apply the cables to a pole line already installed in the location. Thanks to that, you can decrease the time required for construction and the costs involved. Environmental factors can affect aerial cables. However, proper installation can reduce the odds of anything going wrong.

What Are the Main Types of Aerial Fiber Optic Cables?

The market offers a huge variety of aerial fiber optic cables. Therefore, you want to pick units that fit your desired application. Check out the main categories and their features below!

Loose Tube

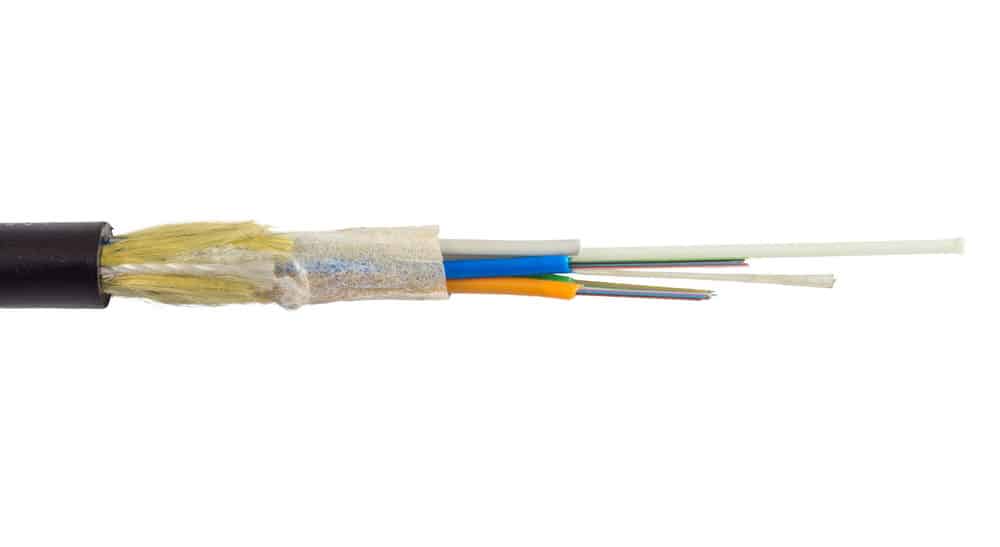

Caption: Loose tubes with optical fibers

The experts indicate this is the most frequent design used in outdoor settings. You can use them for both ducts and lashed aerial installations. Furthermore, loose tube units come in variants with and without gel. The version without can count up to 288 fibers, while gel increases the number to 432.

ADSS: All-Dielectric Self-Supporting Cables

Caption: ADSS 18-core optical fiber structure

The main advantage of this design is that it doesn’t contain any metal. Therefore, you can position this cable close to power lines with high voltage. It’s possible to position them between poles without requiring to place an independent messenger to connect the cable. Furthermore, you can use pretty much any length, including medium and high-span options.

Figure-Eight Cables

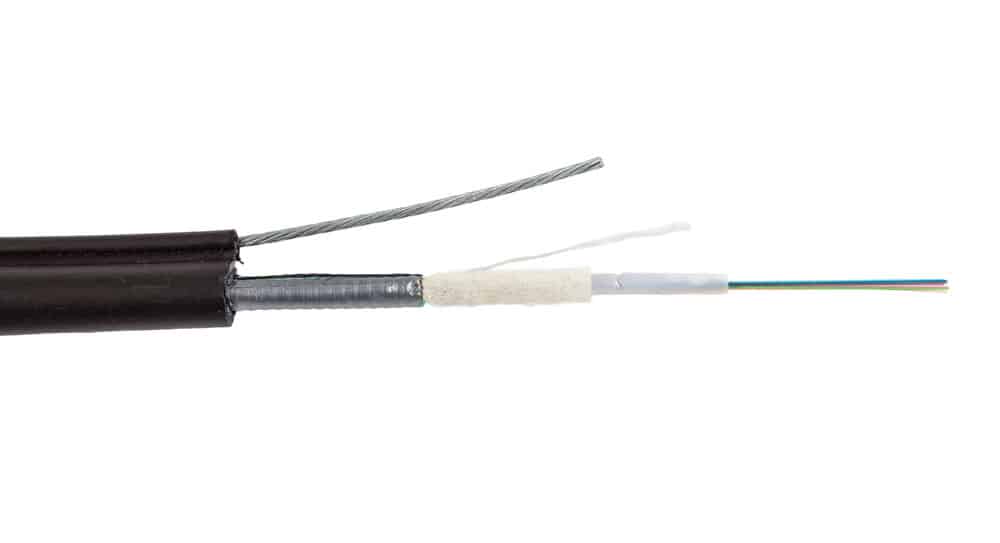

Caption: Figure-eight optical fiber cable close up

These units feature a special design that usually doesn’t have more than 288 fibers. The minimum count is usually 12, and the main advantage is a steel messenger. Therefore, the installation of any building or pole should be simple. You can use short spans, but make sure to avoid power lines with high voltage. The steel messenger makes them unsuitable for that option.

Ribbon Cables

The classic ribbon cables have three different variations. So, the lowest option has 72 fibers per tube and the highest 288. You can also choose the 144-fiber variant. All these fibers surround the middle unit. Therefore, you can access specific ribbon stacks and tubes individually. Thanks to that, you can apply mass-fusion splicing.

Gel-Free Cables

The main advantage of a gel-free design is that it’s mess-free. So, you won’t find a messy filling that requires cleaning ribbons. Therefore, the areas where you splice and work will be cleaner than with standard units. As for the fibers, they go from 12 to 864 units.

How to Improve Speed and Efficiency of Aerial Fiber Deployment

Generally speaking, you can deploy aerial fibers quickly. Furthermore, it’s a more affordable option than going with buried installations. Then, what can help to enhance the efficiency and speed of deploying aerial fiber cables? The crucial part is planning. Therefore, make sure to analyze and test everything.

What Factors Have an impact on the Aerial Environment?

The surroundings will affect the aerial cables after you finish the installation process. Therefore, you should consider various environmental factors, including but not limited to:

- Strong winds

- Heavy rainfalls

- Snow and ice loads

- Large temperature variations

All these can lead to natural contraction and expansion of your cables. Therefore, the installation should handle storms that could occur in those spots for years after the network setup.

A stiffer design can reduce fiber strain and overall stress during storms. Therefore, you’ll ensure increased longevity and improved performance of the cables.

Do you know what the problem of meeting mechanical expectations is? They provide optimal performance but affect how the aerial fiber looks. Therefore, the reinforcing rods lead to a flat cable design. On the other hand, it’s possible to have an element independent from the sheath but with an acting reinforcing purpose.

You should go with rods within the heath jacket because they look better. Furthermore, those rods ensure cable suspension with dead-ends and additional accessories. A critical thing to underline is that these designs prevent cables from splitting. Therefore, they are crucial when their tensile integrity is in danger. It could happen because they separated from the primary sheath.

Picking Your Components

What is your goal when setting up aerial fiber cables? The first goal is to ensure everything works properly. Furthermore, you want the installation to have maximum longevity. On the other hand, it shouldn’t cost you more than you planned. That’s where the importance of choosing components comes into play. Check out these questions to ask when selecting the desired items:

- Is it possible to maintain a consistent design throughout the entire setup?

- What tools do you require for the project? If you need additional accessories, secure them on time. That way, you guarantee you’ll be ready for the project. Therefore, nothing will surprise you in the field.

- Do you have sufficient cable length? If necessary, secure additional wiring. Furthermore, check the poles and other equipment items.

- Are the cable dimensions acceptable for the turf? The installers and subscribers should approve the equipment. Therefore, make sure to discuss it with them if necessary.

- Will the network upgrade in the future? If yes, you should design the parameters to meet the potential update requirements. Therefore, consider that option with installers and other relevant parties.

Conclusion

Aerial fiber cables are a convenient solution and can make the job easy for designers and installers. If you need assistance in choosing the right cable assembly, don’t hesitate to contact our expert consulting team!