The network of cabling and wiring is a critical part of any residential or commercial building. Wires and cables deliver power to the whole infrastructure of any construction, and thus, you must ensure that the system is a reliable connection. This blog post will tell you about different types of building wire and cables and how you can identify them for your use.

Table of Contents

- What is a Building Wire and Cable?

- Common Types of Building Wires

- Common Types of Building Cables

- How to Identify Wires and Cables

- Conclusion

What is a Building Wire and Cable?

There is only one conductor in a building wire. However, there are multiple building wire conductors in a building cable. They bundle together in a thermoplastic or a metal covering.

The electrical current passes from a power source to the device in any building through building wires and cables. These devices are outlets or light fixtures. They run through cable trays, rigid conduits, and raceways. You can use building wires to set up new circuits or extend old courses inside the ceilings and walls of commercial buildings.

You must pick the right size and install these building wires and cables correctly to ensure a continuous power flow. Various standards identify different categories in building cable types. These standards include National Electrical Code (NEC), Mexican Electrical Code, CSA standards, Underwriters Laboratories (UL), and Association Nacional de Normalización y Certificación del Sector Eléctrico (ANCE) Standards.

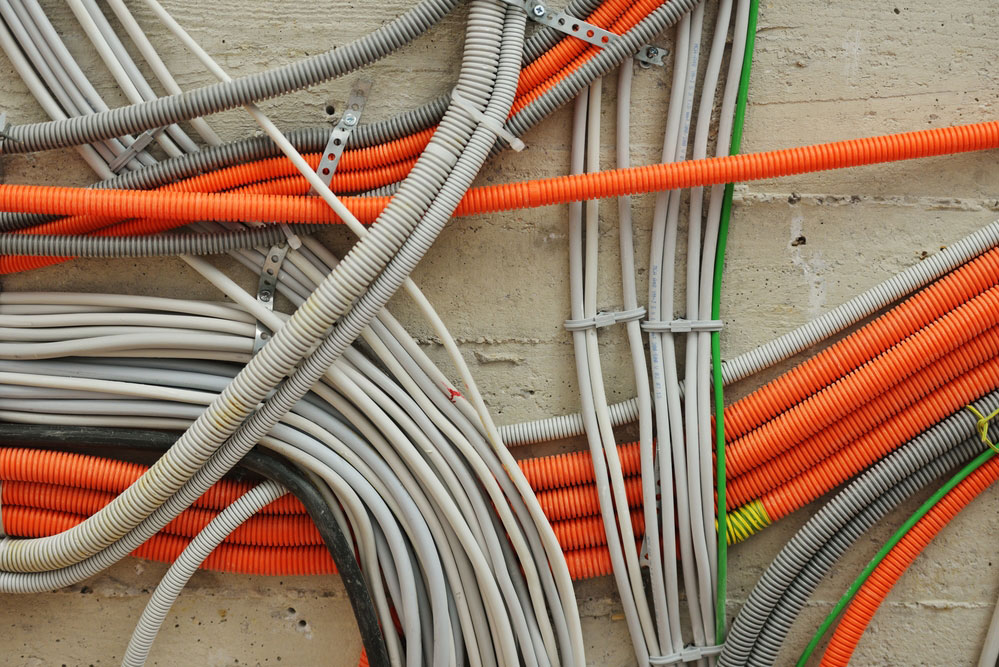

Image: cables on walls in a new house

Common Types of Building Wires

Based on the insulation and jackets, there are three types of building wires. These are:

THHN Building Wire

THHN stands for thermoplastic high heat-resistant nylon wire. It is a coated wire and runs through cable trays and rigid conduits. This high heat-resistant wire can withstand a maximum temperature of 90 degrees Celsius, and the maximum voltage rating of these wires is 600 volts. You can use this general-purpose wire indoors for appliances, control circuits, and machine tools. Its nylon jacket offers protection against abrasion and shock. Also, it provides electrical protection to the inner thermoplastic insulation and copper conductors from getting damaged.

TFFN Fixture Wire

TFFN stands for thermoplastic flexible nylon, and this coated wire runs through raceways. You can use this for commercial building wiring for fixture wiring to power light fixtures in walls and ceilings. Compared to THHN, it is more flexible but has less resistance to heat. Also, you can find it in narrow gauges, including 16 and 18 AWG (American Wire Gauge) copper wire.

XHHW Building Wire

XHHW stands for cross-linked polyethylene high-heat-resistant water-resistant wire, and this coated building wire also runs through raceways. The XHHW wire jacket is thicker and offers more protection than the THHN jacket. As a result, it has more resistance to chemicals, ozone, and abrasions. Further, its cross-linked Polyethylene insulation has higher flexibility than other thermoplastic insulated wires. You can use it for complex electrical projects with tight space bends as it can easily flex and bend.

Common Types of Building Cables

Also, based on the construction, there are three types of building cables. These are:

Armored building cable

Armored building cables are an assortment of insulated wires with a plastic coating that forms a bundle. This bundle has the protection of a corrugated metal jacket, also known as a sheath or cord, which provides grounding and works as a conduit. You can also call these electrical cables BX cables or MC (metal-clad) cables. These cables can handle accidental penetration very well. However, these are heavy and tough to handle. You can use this cable in applications where cables can damage through mechanical and environmental factors under normal conditions, such as in power circuits in industries or commercial properties.

NM-B building cable

NM-B cable is a flexible electric cable where three or four-wire conductors bundle together inside a thermoplastic jacket. This jacket or sheath is heat-resistant and non-conductive. Among these three-four wires, there is one wire for grounding also. You can handle it quickly as it is lighter than armored cable. Further, its sheathing is flexible, which helps you straighten it out quickly. These cables are suitable for dry locations only, like interior electrical wiring. Avoid using them in outdoor areas where cables tend to get wet. You can use these cables for residential and commercial electrical applications like power for outlets, appliances, and electric lighting.

Service entrance cable

Service entrance cables or SE cables help to transfer power from the main breaker to the sub-panel near residential or commercial buildings. According to NEC, service cables are mainly meant for services only. These cables have a maximum voltage rating of 600 volts, and you can use them in both dry and wet conditions. Depending on the product type, these cables may have conductors rated XHHW2 or THHN/THWN.

There are two service entrance cables, namely, SER and SEU.

SE-R: SE-R is around SE cable with four conductors and a bare neutral conductor. You can use these cables above the ground in branch circuits or feeder panels.

SE-U: SEU is an unarmored U-flat SE cable having two-phase conductors with a concentric neutral. The cable’s stranded neutral conductors wrap around it to give it an oval shape. You can use them in single-family residential buildings to transmit power to the meter base from the service panel and then carry it to the distribution panel board.

How to Identify Wires and Cables

The industry standards give letters and wires color to make them suitable for a particular purpose. It is easier for an electrician or an expert DIYer to do electrical work in installed wiring and cabling.

Naming and Taxonomy:

The National Electrical Code gives letters to the wire to identify its capabilities. The standard notes for wires include THHN, THW, or XHHW.

Here is a list of letters you may see on residential wire installations.

- T- indicates thermoplastic insulation

- H- indicates heat resistance

- HH- indicates high heat resistance

- W- appropriate for wet locations indicating protection from moisture

- N-have nylon coating, oil and gas resistance

- X- highly flame retardant, synthetic polymer

Wire colors

The below list tells you the color codes that industry standards gave to the wires.

- Black: Black is a hot wire for outlets and switches

- Red: Red is a hot wire for switch legs and connects to smoke detectors

- Blue and yellow: These are also hot wires that electricians pull through conduits. You can use blue wires for three- or four-way switch applications while using yellow for switch legs to control fans and lights.

- White: This is a neutral wire (this wire can be hot and may have a red or black indication to show that it is no longer a neutral wire)

- Green or Bare copper: You can use this wire for grounding purposes

Another widely accepted industry standard for non-metallic or NM-B cables gives color to its jackets. Based on the specific color coding, it is easier to identify the gauge of the wires inside the line.

- White-It indicates a 14-gauge wire used for lighting circuits

- Yellow is a 12-gauge wire used in houses for powering outlets and other home appliance wiring.

- Orange indicates a 10-gauge wire in water heaters and air conditioners.

- Black: It indicates an 8-gauge or lower than 8-gauge wire that you use for feeding a subpanel or an electric range or oven.

Conclusion

Although the wiring hides inside walls and ceilings, they are crucial to a property’s electrical system. If you need help with building cables and wires, contact Gloom. We have all types that suit your residential and commercial applications and deliver superior performance.