The connector series is complex, and you must differentiate between them before choosing among them. When creating a wire harness, it is essential to think about what type of connector is best for you. Ultimately, this decision will affect the choice of other components and, as a result, will determine whether the connection is fit for your situation or not. Let’s dig inlets.

Table of Contents

- Understanding Electrical Connectors

- Composition of Electrical Connectors

- Specifications of Electrical Connector

- Types of Electrical Connectors

- Conclusion

Understanding Electrical Connectors

Electrical connectors join two wires and create an electrical path between two devices to connect. This connection can be between two electronic pieces of equipment or a device and a power source. Moreover, the link can be permanent, semi-permanent, or temporary, depending on the circumstances.

The connector comprises two parts, a male end and a female lot. The male connector part or the plug has pins and is moveable. However, the female connector or jack has insertion points where you enter the plug’s pins. Jacks are usually stationary and can allow you to plug in different wires of the same plug design.

Since when you use a connector, you can easily make or break the connection. Thus, they have drastically reduced the labor and cost of manufacture, cable assembly, and installation of devices. Hence, connectors are now an essential component of any wire harness.

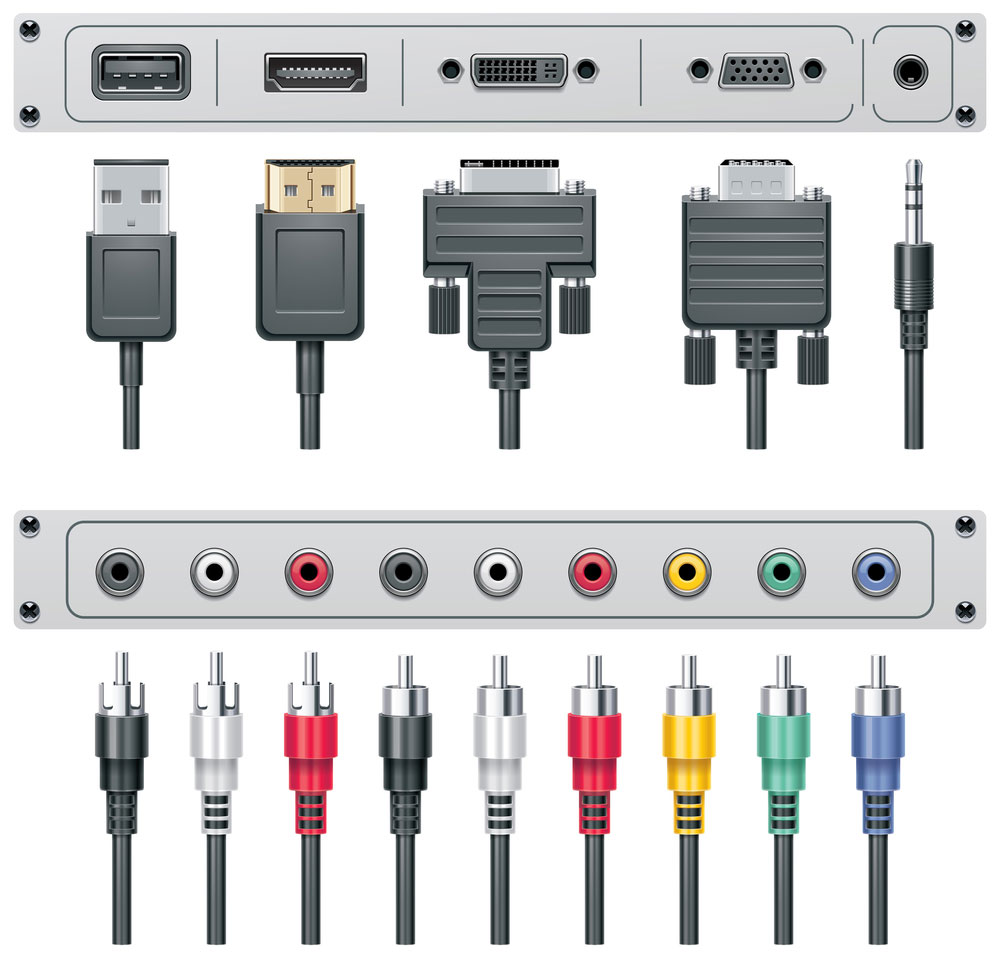

Caption: Video and audio electric connectors

Composition of Electrical Connectors

A primary wire connector comprises two portions, the housing, and the terminal, to make an attachment efficient.

Housing

Housing is the casing or structure that contains the terminals, and the manufacturers make it with insulation material like molded plastic or ceramics. It ensures that the connectors make a stable connection. Moreover, it also prevents the electrical point of attachment from short-circuiting and other potential hazards.

Terminals

The terminals or pins are the exaggerated points of the wire connector from where the electrical signals pass into the insertion points of jacks. Almost all airports are metals like copper or iron, but some may have other conductors like carbon or silicon.

Caption: RF transmitting connectors with Male and female receptacles

Specifications of Electrical Connector

You need to consider a few specifications before selecting the connectors. These parameters will determine the type of connector, insulation, etc.

Performance Parameters

Performance parameters are those conditions under which the connector has to operate.

- Current: The rate of current, on which the manufacturers have accommodated connectors is its current rating. Thus, you should check and see whether the equipment is fit for you or not. Typically, the companies rate the connector in Amperes or Amps and they are available from 1A to 50A.

- Voltage: Voltage rating tells the range of voltage, that a connector can bear. the companies rate it in volts (V) and classify it further as AC or DC. Typical ratings are 50V, 125V, 250V, and 600V. However, custom options are available too.

- Temperature: The temperature at which a connector can operate without issues is its temperature rating. Thus, manufacturers label it so that a connector does not melt and is in a safe zone.

Physical Parameters

Physical parameters or design specifications describe how the manufacturers have designed the connector.

- Contact Pitch: It is the distance between the pins or the terminals of a connector. However, the greater is the contact pitch, the lesser is the pin per area on the connector. Thus, it reduces the electrical arcing and hence, interference. But, it does increase the size of a connector making it unfit for smaller areas. The units of contact pitch are millimeters or mm.

- Number of Contacts: As the type of contact pitch changes, the number of individual conductive elements or contacts also varies with every other type of connector. So you can choose the suitable one on this parameter as well.

- Material: The casing of the connector is always of the same material. However, the conductive part of the connector can be different for different types. Consequently, the performance, stability, conductivity, formability, and resilience varies from material to material. Some common metals used are Brass, Phosphor Bronze, Beryllium Copper, and High Copper Alloys.

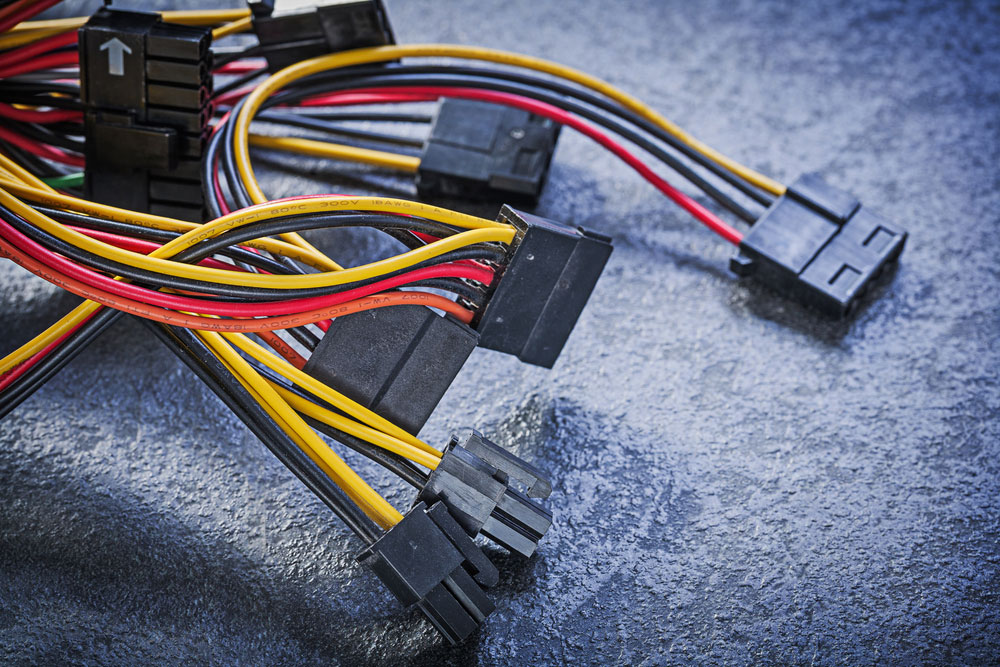

Caption: Single electric wires with connectors

Types of Electrical Connectors

You can classify the common types of connectors based on features, connector level, function, and kind of termination. The following details further enumerate the stance.

Connector Features/Properties

For some applications, connectors with these features might be the first user.

- Keyed Connectors, to connect only when it is in the proper orientation. This way, you can minimize accidental damage to the terminals and will not insert them in the wrong socket.

- Locked Connectors so that you can fix the connectors in place and do not have any loose attachments.

- Hermetically Sealed Connectors, where you need to seal the connection with waterproof and pressure-proof material. An example can be the wiring done in machinery working underwater rocks.

- Water Resistant Connectors, where you need to seal the connection with waterproof material. An example can be the wiring done in submarines.

- Moisture/Oil Resistant Connectors, are designed to protect the connection from moisture and oiliness in the environment.

- EMI or RFI Filtering, is usually present at the top of buildings and comes in handy to prevent electromagnetic or radio frequency interference.

- ESD Shielded Connectors that shield the wiring from the electrostatic discharge around it.

Connector Level

Following are the five categories or levels in which you can subdivide the connector types.

- Box to box or input/output

- IC chip or chip to package

- IC package or Package to Board

- Wire to board or between subassemblies

- PC board to board

Caption: Connectors with the source of electric power

Connector Function

Many of the connectors are application-specific. Yet, most of them are chosen based on their method of connection.

- Terminal Block, where multiple wires are connected to a single termination point and enclosed in a housing of insulating material. These include PCB blocks, barrier strips, and pluggable terminal blocks

- Binding Posts where wires are fastened with screws or clamps and the other end has the terminal, pin, or plug. Moreover, their common application is in audio or electronic testing devices.

- Plugs and Sockets where there is a female connector or socket with openings to insert the pins, and the male connector with pins or terminals. Common examples are the HDMI, D-sub, and USB connectors.

- Rack and Panel, which you can use to connect the stationary equipment with removable electronic parts. It is the first choice of electricians where you need space and reliability.

- Blade, which consists of individual wires that you will connect with the blade receptacles in speakers or thermostats for point-to-point connections.

- Ring and Spade, in which the single wire is connected, just like blade connectors. However, the connection is made secure with a threaded post or screw/bolt. Suitable for point-to-point connections.

Connector Termination

Sometimes, the connectors are also divided into classes based on how they terminate the wire with the connector.

- Insulation Displacement, where you don’t need to strip off the insulation layer of the cable. Just fix the connector onto the wire end. However, the blades inside such connectors might damage the wire and lessen the current carrying capacity.

- Crimping makes an easy to separate connections between the connectors and wires. In this method, you will insert the stripped cable and crimp it with the help of a special tool, it is easy and cost-effective hence the preferable method.

- The soldering method is comprised of melting the filler metal on the joint of the wire, thus making a fused connection. If a professional does it, it can provide a very robust and smooth connection.

Caption: Different connector cables and plugs

Conclusion

Connectors can be of different types, each designed for a specific use. For example, you need a different connector type for damp conditions and places with much electrical discharge. Hence choosing the correct connector will make your electrical connection solid and reliable. Here at Bloom, we offer an automotive wiring harness with attention to detail. To avail of our services, contact us now.