A high-voltage wire can ignite a spark in the air and give out electrical shocks. Thus, you need a special one to handle these problems. However, before using one, you must know its characteristics and composition to make the right choice among a wide range.

Table of Contents

- What are high-voltage wires/cables?

- High voltage cable composition

- Classification of high voltage cables

- Common types of high voltage cables

- Conclusion:

What are high-voltage wires/cables?

High voltage cables help in electric power transmission at an operating voltage greater than 1kv. Like other cables, it also has a conductor and insulation; however, the air is not a part of the insulation here, unlike overhead cables. High voltage cables have varying uses in ignition systems, instruments, direct current, and alternating current power transmission.

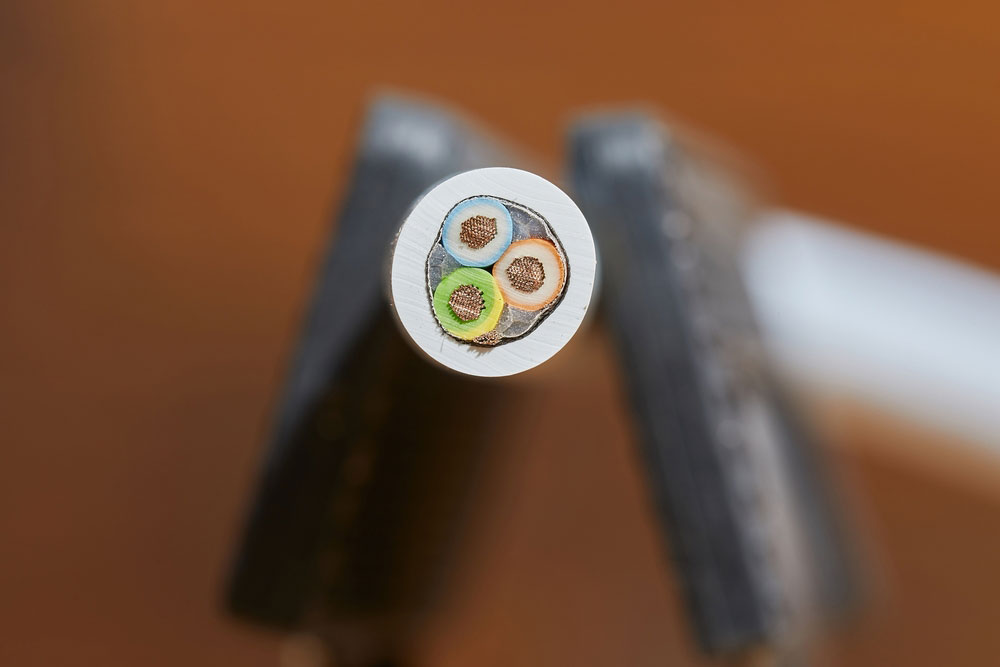

Image: high voltage cable

High voltage cable composition

The design of high voltage cables has the following layers:

Conductor

The conductor is the central element carrying electric current. And it should be Class 2 conductors made of electrolytic copper or electrolytic aluminum of high purity.

Internal semiconductor screen

A Semicon layer surrounds the conductor to distribute the electric field on the conductor’s surface.

Insulation

As the high voltage cables have a high electric field, insulation is critical. And insulation’s thickness and material decide the maximum voltage carrying capacity. It comprises different materials, including ethylene-propylene rubber (EPR), polyvinyl chloride (PVC), and cross-linked polyethylene (XLPE).

External semiconductor

A cross-linked semiconductor material surrounds the insulation, and it forms perfect contact with the insulation layer.

Metal Screen

There is a metal screen of copper fibers outside the semiconductor layer in helical form, and this metal screen covers the whole perimeter of the cable uniformly.

Protection against water

Cables have a tape of hygroscopic material under the sheath, having longitudinal seals. For a double sealing, a series of hygroscopic wires cover the conductor. This material prevents the penetration of water within the sheath.

Inner sheath (only in armored cables)

Armored cables have an armor pad between the metal screen and the armor. Generally, PVC and halogen-free polyolefins form this armor pad, also known as a separation cover.

Armour (only in armored cables)

Some cables that face the mechanically stressful condition have armor comprising metal stripes and wires covering the inner sheath. The armor offers protection against external aggressions. In single-core cables, generally, aluminum forms the armor.

Outer sheath

This outermost layer of PVC or halogen-free polyolefins protects the high voltage cables from mechanical and chemical stresses. It is a uniform and continuous coating and offers protection against moisture penetration, harsh weather conditions, and knocks and abrasions.

Image: composition of a high voltage cable

Classification of high voltage cables

You can classify these cables according to:

Number of cores in the cable

Single-core: There is only one conductor, either aluminum or copper, in single-core cables. And the thickness and gauge of the single conductor can vary depending on the application. Further, a single-core cable is either solid or stranded. The solid ones have a thick diameter and higher rigidity, while the stranded ones have higher flexibility.

Multicore cables: These cables have two or more conductors in a single outer sheath to serve different power supply purposes. Also, in multicore cables, every single wire has its insulation.

Type of insulating material

Paper insulation can be used in industrial applications and power distribution in exposed form, directly buried structures, or underground conduits. As a result of the electrical and mechanical properties of the liquid that impregnates the paper tapes, it is a very reliable and economical insulation solution.

Impregnated paper insulation means high-density paper tapes impregnated with high viscosity oil-like compounds. You can use long lengths of these cables in high voltage DC links up to hundreds of kilometers. As these cables have desirable physical and electrical properties, they are suitable for transformers.

Ethylene propylene rubber (EPR) is a copolymer made from ethylene and propylene. As EPR has excellent dielectric strength, it is a good insulation material. Further, EPR insulated cables have high thermal stability and a temperature rating of -55 degrees Celsius to 150 degrees Celsius. In addition, these cables are very flexible and thus are easy to install. Last, they offer better flame resistance than other insulation types.

Polyvinyl chloride or PVC is a cost-effective electrical insulation material. Also, it has excellent aging properties and can last for 25-30 years. In addition, it is a very versatile thermoplastic, and you can easily modify it with plasticizers, lubricants, and stabilizers. As a result, PVC insulated cables show resistance against flame, oils, acids, alkalis, and abrasion.

Cross-linked polyethylene or XLPE is a thermoset insulation material suitable for very high voltages. And it offers excellent tensile strength and impact resistance to the cable. Further, it shows high thermal stability at high temperatures ranging from 70-90 degrees Celsius.

The voltage for which they are manufactured

Low tension

- suitable for voltage up to 1000v

- insulation thickness is 15mm

High tension

- suitable for voltage up to 11kv

- insulation thickness is 4-5mm

Super tension

- suitable for voltage up to 33kv

- insulation thickness is 8 mm

Extra high tension

- suitable for voltage up to 66kv

- insulation thickness is 16mm

Extra super tension

- suitable for voltage up to 132kv

- insulation thickness is 23mm

Image: power cord cross-section

Common types of high voltage cables

The common high voltage cable you see in life include:

Teck Cables

These flexible, compact, and reliable cables resist corrosion and mechanical stress. And you can use these cables in chemical plants, primary and secondary industries, general factories, and refineries. In addition, they are available in different combinations of conductor size, armor type, voltage ratings, etc.

- Firstly, they annealed and bare copper in the stranded form to reduce the diameter.

- Secondly, there is the insulation of cross-linked polyethylene

- Thirdly, there is a layer of plastic PVC

- Then, there is a layer of interlocking aluminum armor

- Finally, everything gets sealed with a coat of PVC.

Shielded Cables

It is available in single conductor or three-conductor cable forms. And its construction comprises of

- First, an annealed and bare copper (solid or stranded) surrounded by a layer of semiconducting material.

- The second is a layer of insulation that surrounds the central conductor.

- Third, semiconducting insulation covering surrounds insulation.

- Finally, there is a lapped or gapped copper tape, which acts as a metallic shield. There is also a metallic shield of corrugated copper tapes or concentric wires.

- The outer jacket comprises either polyvinyl chloride or Polyethene.

Concentric neutral cables

These are also available as single conductor or three-conductor cables. You can use them in dry or wet conditions for different installations. These are either jacketed or unjacketed, however, jacketed cables are more common.

Generally, the conductor is bare and annealed stranded copper; however, you will also find solid and tinned copper conductors options.

These cables got their name due to the concentric neutral conductor, a tin-coated or bare copper wire. The insulation shield has a helical covering that acts as a metallic component and a neutral wire.

Submarine Cables

Depending on the voltage requirements, you can use either a solid dielectric cable or a self-contained liquid-filled cable for submarine installations. For high voltages, an SCLF cable is more suitable. Its construction comprises:

- Firstly, a bare annealed copper conductor, which is compact and stranded.

- Secondly, a semiconducting conductor shield.

- Thirdly, a layer of lead alloy sheath offers flexibility, compressibility, and resistance to corrosion and moisture. Such conditions are highly prevalent in submarine conditions.

- Finally, an outer covering of PVC or PE jacket and metal wire armoring is enclosed.

Mining cables

Mining cables are used in mines. They need frequent reeling and de-reeling, and thus these cables have unique designs. There are several types of mining cables, and some of them have a voltage rating of 25 kV. The construction comprises of

- Firstly, three shielded and insulated, bare, and annealed copper conductors.

- Secondly, two bare ground copper wire conductors (annealed, tinned, bare, and stranded).

- Thirdly, a ground check wire (annealed, bare, and stranded).

- Lastly, an outer jacket (EPR insulation, nylon braid). An outer elastomeric jacket holds the whole assembly tightly so that there is no snaking or corkscrewing in cables.

Aluminum sheath cables

You can use them for exposed or concealed wiring in both wet and dry locations. They are easy to install in ventilated or unventilated areas. They can have single, two, three, or four conductors. Their construction comprises:

- First, annealed, bare, stranded, and compressed copper conductors.

- Second, an insulating core is enclosed in a liquid and corrugated aluminum sheath.

- Finally, an outer PVC jacket.

Image: high voltage shielded cables

Conclusion:

Different applications require different kinds of high-voltage cables. It is essential to pick the right cable with suitable conductors and insulators to avoid outages. If you cannot decide what cable would be ideal for your application, technical experts from Cloom can help you.