In recent times, you will notice that the automotive industry has been using the new term MIL SPEC when marketing cable and wiring harnesses, sensors, and various electronic components. As a result, consumers have started believing that MIL-SPEC is the general specification for all types of automotive products, as they are sold only like this.

This post will help you clear some air related to this term. As mil-spec products are a little more expensive than the regular ones, you must know your needs before you invest and give an extra cost.

Table of Contents

- What is mil-spec?

- Mil-Spec standards for cable assemblies

- Five key factors to determining whether you need mil-spec cable assembly for your application

- Conclusion

What is mil-spec?

The US military has specific standards in everything they do. All these military standards ensure compatibility and reliability among systems in tasks related to the defense industry.

The “mil-spec” marking on any product indicates that the product meets specific military standards (MIL-STD) or military specifications (MIL-SPEC). You might notice other formal terms similar to mil-spec on military developments. These include:

MIL-STD (standards in defense)

MIL-DTL (detail specifications of protection)

MIL-PRF (performance specifications in the defense industry).

There are two specific military standards used in this industry which are MIL_STD 461F and MIL_STD-810G. The first or the 461 standard specifies the standards for testing electronics for their compatibility with electromagnetic radiations. The second one, i.e., 810, identifies a wide range of measures for environmental conditions. The government uses these standards when choosing vehicles, aircraft, vessels, and other special units.

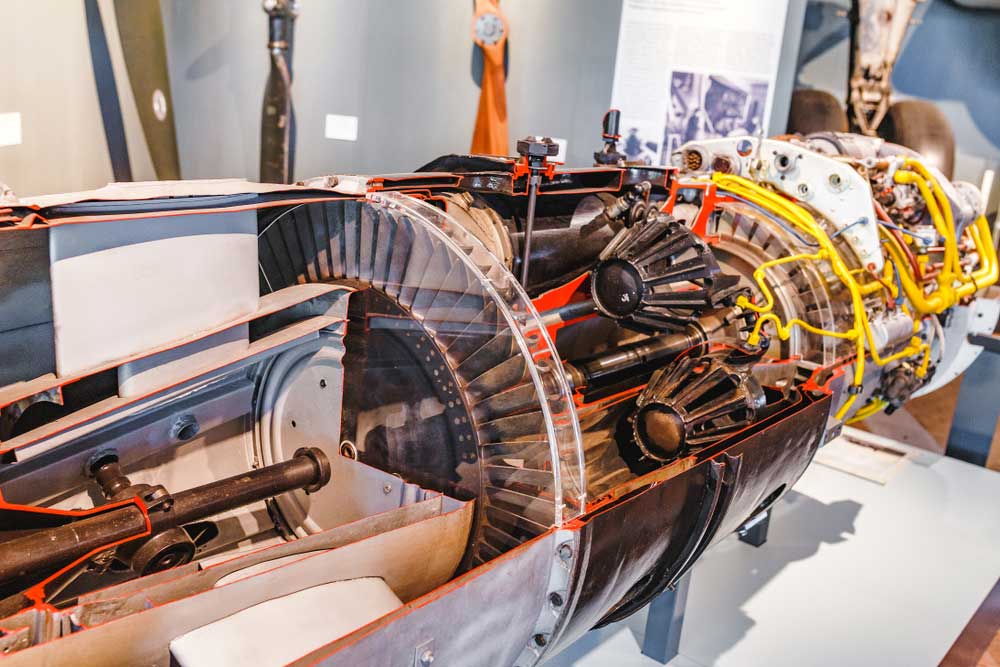

Caption: airplane engine closer look

Mil-Spec standards for cable assemblies

All cable manufacturers follow some standards when they decide on several aspects of the cables and the wires, including the application environment, manufacturing materials, type of applications, and cable construction. These standards make Mil-spec cable assemblies rugged, lightweight and durable. And they can perform well in military operations by reducing vibrations in applications.

There are several Mil-spec standards; however, few are famous for cables and wires assemblies.

M22759 (SAE AS22759)

When a wire comes with this standard, it can work in extreme conditions, such as in aerospace applications. You can use this wire in electronic systems prone to moisture or for aircraft engine controls.

M16878

You can also write it as MIL-W-16878; a wire with this standard can handle high voltage and extreme temperature conditions. Several insulation materials, including PVC, PTFE, ETFE, and Polyalkene-PVC, are used in this wire manufacturing. Products with these wires have different varieties; thus, this wire has different slants. For example, M16878/5 is suitable for electronics in extremely high temperatures, while M16878/4 is suitable for appliance wiring, power supply, and harnessing.

M25038

The standard can work in harsh environments with high vibrations and direct flame exposures. The critical circuits in aircraft use this kind of wire.

M13486

This wiring standard is suitable for cable assemblies used in low-tension applications in the military industry. You will find these cables primarily in tanks, trucks, and other ground vehicles, and this military standard is also available in different slants to suit various product requirements. Another property of these cables and wires’ resistance to moisture and abrasion is another property. Also, they show high flexibility even at low temperatures.

M5086

This standard wiring wire is suitable for various applications across several industries, including military, industrial electronics, and aerospace. These wires and cables are best for application environments with abrasion, high impact, and high chemical exposure.

Five key factors to determining whether you need mil-spec cable assembly for your application

If you see any wiring harness that is mil-spec rated, it means it has high-quality standards and will be a bit more expensive than its counterparts. Luckily, not all applications necessarily use such cables and wires, so you can avoid using mil-spec cable assemblies to save money.

- Suppose your application is a critical one. It means you can afford to fail your cable assembly, as failure can result in heavy losses. So, if your application is vital, you must surely use mil-spec cable assembly to continue running with the reliability and durability of such cables.

- All the mil-spec cable assemblies are meant explicitly for harsh and unpredictable environments. So, if your application environment is poor, the mil-spec cable assembly is a wise idea as it will protect equipment from moisture, abrasion, and corrosion.

- You should choose mil-spec assembly if your application environment involves constant vibration and motion. In most military situations, the equipment has to undergo vibrations and movement due to rough terrains and challenging conditions. Of course, you will not want your equipment damaged in such harsh conditions. Mil-spec cable assembly keeps your equipment going in all types of adverse situations.

- If your applications involve exposure to electromagnetic or radiofrequency radiations, you need a mil-spec cable assembly. The mil-spec cable assemblies shield your equipment from all types of EMI or RFI radiation, which is essential for the long life of the equipment.

- Apart from the above conditions, some applications require mil-spec cable assemblies to take advantage of the equipment. This selection may be due to safety concerns or the reliability of the products. Sometimes, you may need mil-spec cable assembly to comply with the industry regulations or requirements.

Conclusion

Cloom is a reliable manufacturer of all cable assemblies and wiring harnesses. So, now it is clear to you when you should opt for the mil-spec cable assembly. Whether you need it specifically for military applications or to meet compliance with specific industry standards, contact us and discuss your requirements with our technicians.