The Push-In Wire Connectors,

The Push-In Wire Connectors, The invention of electricity was undoubtedly revolutionary. Electrical installation inevitably followed suit because how else would we harness those electric juices? Wire installation wasn’t always a one-person job.

In the early days, mechanical experts and electricians worked hand in hand to ensure that you have that well-lit house visible from space.

Sounds like a lot of work if you ask me, especially in this DIY generation.

Reliable and handy push-in electrical wire connectors were the perfect replacement for those traditional labor-intensive installation methods. Let us zoom into this world of push-in wire connectors and find out what makes this design stand out.

Table of Contents

- What Are Push-In Wire Connectors?

- How Do Push-In Connectors Work?

- How Do You Use Push-In Wire Connectors?

- Benefits of Push-In Wire Connectors

- Push-In Connectors vs. Wire Nuts

- Push-In Connectors vs. Screw Connectors

- Keeping Up With NEC Safety Regulations

- Applications of Push-in Connectors

- Conclusion

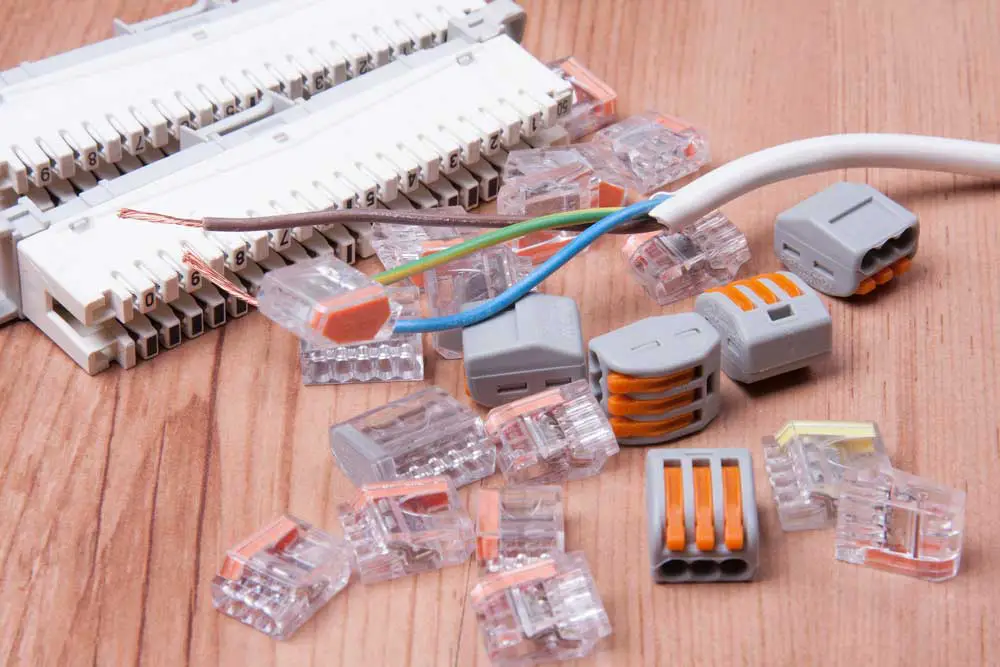

What Are Push-In Wire Connectors?

Wires connected to three push-in wire connectors.

Push-in wire connectors, with their unique style of insulation, are the epitome of efficiency in the realm of electrical installation. They are common in commercial and residential lighting, digital signage, and other illustrious building electrical systems.

You can consider them a sweet alternative to the archaic twist-on connectors or wire nuts of yesteryear.

Push wire connectors consist of spring steel clips and copper strips housed in a clear plastic casing. To ensure everything stays in place, designers fit insertion holes into the end plug that securely trap the spring within the housing.

You must strip a small part of the insulation from the wire and insert it into one of the ports. Can it get any easier than this?

The connector utilizes the spring’s constant compressive force to firmly press the inserted conductors and secure them against the metallic bus bar.

Even if there is any temperature change, the spring consistently maintains its constant compression state. This fixes the thermal cycling problem associated with the predecessor connector types.

Every connector can hold as many wires as the ports present on the connector.

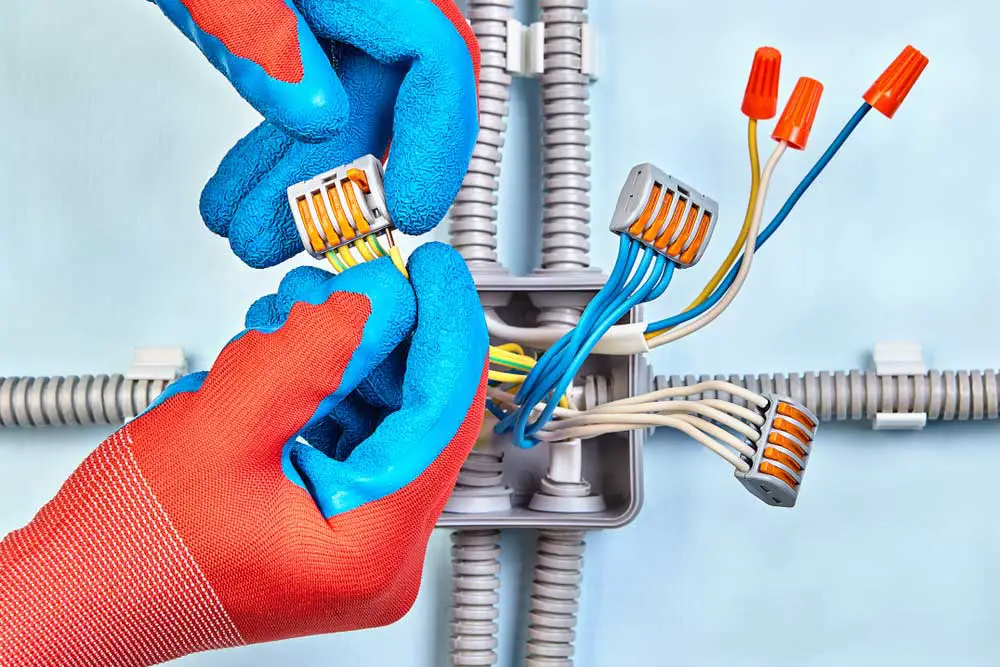

How Do Push-In Connectors Work?

An electrician in protective gloves puts a push-in wire connector on copper wiring.

The working principle takes more of a self-latching approach. You don’t need much—just your wires and the springs hugging it out.

The internal spring clamp secures the stripped wire in place. Once you insert the wire, it presses against the flat copper strips, making a connection.

The internal tab present in the connector ensures the conductor firmly contacts the bars.

The clever color coding allows you, as an installer, to navigate the cables easily. This has the bonus of making maintenance and replacement a walk in the park.

How Do You Use Push-In Wire Connectors?

Hand stripping a wire using a wire stripper.

When installing these wire connectors, insert the wire conductor ends (reasonably stripped to remove insulation) into the connector’s ports.

Only one conductor goes into each port. For stranded wires, you’ll need to twist the stripped wire tips before insertion to make a more secure connection.

The release feature lets you effortlessly remove and reinsert the wire as needed.

Although you may argue that push-in connectors, by design, require a single installation, their reusability is not impossible.

It’s rather conditional. Sometimes, you can only reuse them with solid wires of the same or smaller size.

Benefits of Push-In Wire Connectors

Aerial photo view of many push-in connectors on a gray metal surface.

If this were a pros and cons list about this type of connector, the pros section would be crazy long.

But here are some of the benefits of using push lock wire connectors:

- The low insertion force required when using the connectors makes them easy to use and requires little to no appreciable energy.

- One can visually verify a connection owing to the connector’s transparent plastic casing.

- The tool-free conductor termination saves installation time.

- The compact size with color coding for easy identification is just awesome.

- Multi-port connectors like this allow for speedy hook-up of multiple wires to a single unit.

- The multi-wiring port units are incredibly useful in preventing overloading.

Push-In Connectors vs. Wire Nuts

An electrician holding nuts and wire connectors.

Wire Nuts, also known as Twist-On connectors, are round little plastic caps that twist over conductor ends to make tight connections.

Inside the plastic caps (usually conical) are metal square-cut springs whose tension forces secure the wires to the connector. Some insulating caps are ceramic instead of plastic for high-temperature applications such as furnaces.

Wire nuts work equally well with solid or stranded conductors. However, you should pre-twist stranded wires to ensure proper mating with the spring. Avoid overfilling the connector with wires, as this increases the chances of shorting two endpoints.

Twist-Ons are also color coded.

You will need to dig deeper into your pockets to afford push-in connectors compared to their twist-on counterparts.

Wire nuts are bulkier compared to push-in connectors.

It is easier to connect push-in connectors than wire nuts making the latter unreliable and difficult for unskilled persons.

Push-In Connectors vs. Screw Connectors

Electrician connecting wire on a terminal.

In some electrical switches or receptacles, you can find screw connector terminals used together with push-in connectors.

Screw connectors are a bit traditional in terms of wiring. They’ll require you to use screwdrivers to clamp the wires to the connector ports. This connection method takes longer and requires considerable practice to master.

To ensure a firm grip, you’ll need to fix the stripped ends of the wire to the screw terminal and then tighten the screw down.

Despite being time-consuming, tool-based, and energy-consuming, the screw connection method results in more secure connections than push-in connectors.

Keeping Up With NEC Safety Regulations

An electrician measures the voltage across two wires using a multimeter.

The National Electric Code (NEC) is a set of guidelines and safety regulations that govern the installation and maintenance of electrical systems in the United States. If operating within US borders, this is a legal pitfall you’ll need to avoid.

Wire connectors play a crucial role in meeting NEC requirements because they provide a secure and efficient means of splicing wires and ensuring that the connection is reliable. The push-in wire connectors, in particular, offer a major advantage.

Not only do they hold the wires in place, but they also offer an encapsulated housing that protects the electrical wire ends from electrical disturbances and serves as insulation.

It’s important to remember that the NEC regulations constantly evolve to keep up with changing safety requirements and technological advancements.

Staying up-to-date on these changes is vital for you or your organization to maintain compliance and ensure the safety of your electrical systems.

Applications of Push-in Connectors

Cable wires with connectors.

The connector design has several modern-day applications. Some examples of application areas are:

- Digital Signage using display technologies like LED walls and projections.

- Retrofit Lighting is popular in interior spaces and residential applications.

- The lighting of offices.

- Residential and industrial wiring systems.

- Wiring of commercial building equipment.

Conclusion

Push-in connectors are a quick and easy wiring method that involves inserting the conducting wire into the connector’s port.

Mostly, professionals consider these connectors for their ease of use and reliability. However, they can also be relatively expensive and dependable when making secure connections.

Nobody enjoys having to redo a task in the name of a bad connection.

Your choice of connectors should therefore consider cost, reliability, and efficiency.