Wiring is the backbone for running cars on track and making money in this niche. Automotive wiring is scary, frustrating, and demanding for someone who does not know what they are trying to do. It is also a hefty process and can be energy-draining for someone who is a complete beginner. Today, we will introduce some race car wiring solutions for an excellent wiring job.

Table of Contents

What to Do for wiring race cars?

Beautiful wiring jobs are essential to a successful race car build, so you should know some electrical knowledge of basic wiring.

Map the operation before beginning

When a mason starts building a home, he first analyzes the map. This step helps him understand the processes he would be going through. Furthermore, this gives him insight into the materials he will need. Just like the mason, it is incumbent upon you to perform extensive research before you embark on wiring your favorite racing car.

It is crucial to understand that racing cars have plenty of colored wires of various gauges or color-coded wiring harnesses connected to assorted automobile components. Therefore, perform extensive research on vehicle parameters before commencing the wiring operation for the racing car. It would help you identify the materials needed for the task ahead.

Diagram and write everything, from the essential supplies to the complex actions. A wiring diagram would serve as navigation for you during the project. When you feel stuck or find it hard to make decisions, this map will help you escape the sharp pinch.

Crimps for vibration and strain

Racing cars are best for rough tracks and have high engine power to match the requirements of the race. Increased engine power means more vibrations, so we recommend crimping wires during the project. Soldering the cables are also a good choice, but it does not mean you weld them together. Also, they might even break under a substantial frequency of vibrations.

We recommend good quality crimps that offer a smooth grip and strong force at the point of contact. If you opt for soldering wires, isolate the joints from vibration. It will help relieve the soldered wires from the strain caused by vibration.

Staggering the solder joints is the key.

As stated, soldering the joints is also something many professionals choose. For example, Jeff Jordan, a wiring wizard from Jordon Innovation, thinks that soldered wires are also effective in building a racing car. You mustn’t splice the joints at the same point when there are plenty of cables. Instead, stagger the soldered connections, so the diameter of the wire remains constant throughout.

Whenever the power wires are soldered, their diameter becomes thick, which may compromise the width of the entire wire. Therefore, stagger the joints by an inch to maintain an even breadth throughout the cable. Remember, you don’t want one thick and another thin portion in the harness.

Strain Relief and Abrasion Resistance

This step is a must-do for protecting your racing wires over a long time. You can place the wiring cables from anywhere, but it is ideal for routing them, so they are less affected by stress. You will use zip ties to bind the wires to lessen the tension caused by vibration or other mechanical forces. Zip ties and clamps are one of many binding tools that help to resist the tearing and wearing forces.

Furthermore, if the bundle of wires is made to route through the sharp gaps or loom, you will use rubber grommets to protect the harness. Usually, when cables pass through openings with sharp edges, they may get damaged when rubbed against them.

Buy high-quality materials and tools.

Knowing the art of wiring the racing car is 50% of the game. Another 50% is buying the right equipment from the right place at the right time. We have heard several people complaining about their wiring wearing down. That happens because they do not invest their money in buying quality materials. Indeed, a pair of crimpers, a soldering ring, or a butane flame costs a little higher, but the cost of getting your car fixed is two times higher.

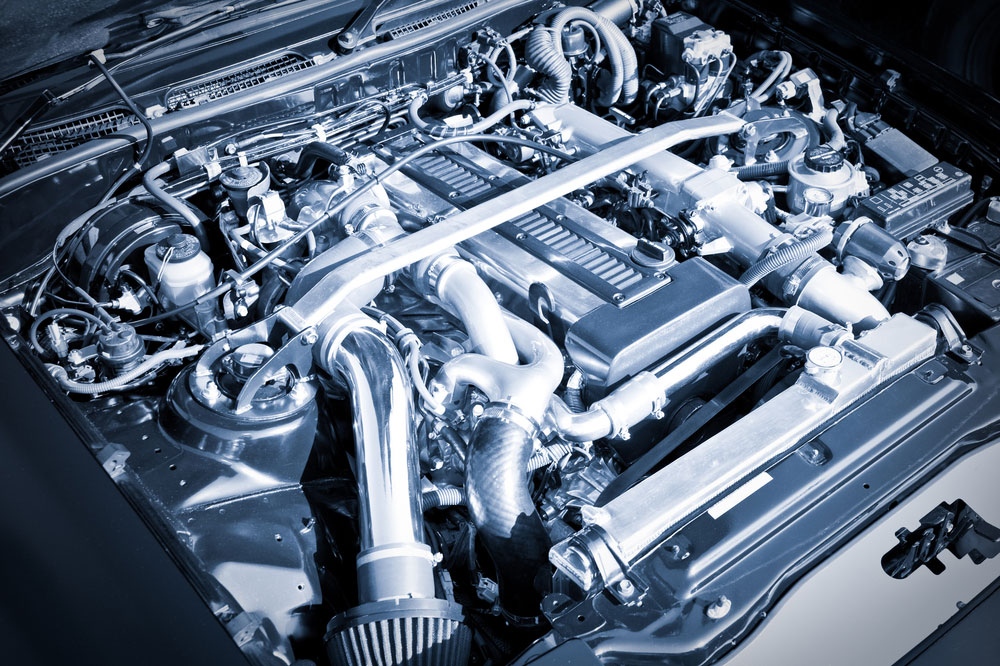

Caption: Inside of a Racing Car

What you shouldn’t be doing for wiring race cars

Lousy wiring is sure to set your expensive car on fire. It can also prove fatal for you due to your negligence. So, you should avoid doing the following for a durable connection.

Don’t Rush Wiring

Consider Patience one of the prerequisites for successfully wiring your racing car. Wiring your racing car is not an easy process to perform, and you must be willing to be patient as you take steps in assembling your wiring cable. If you act hastily, the result would be a bunch of wires in an unorganized manner, only waiting to be torn apart from frequent vibration. It may even disappoint you, and you might not touch your racing car for another season.

Don’t join and route

Avoid crimping or soldering both ends of the wire together and routing them. This would result in a big mess of cables. It is why you should follow the map because it saves you later. It gives an insight into when to join wire A with wire B and where it should be routed.

Avoid soldering in the vibrating area.

As discussed in the previous section, soldering is a good option for connecting both ends of the wire. The offers smooth resistance; however, soldering may break if the harness has been routed through the most vibratory area of the racing car. It would help if you were using crimps in these areas. It would help if you were using crimps in these areas. A damaged soldered wire can easily cause a short circuit and may even set your car on fire.

Don’t use pliers when you can use crimp.

Remember the phrase ‘the right tool at the right time to stress the importance of dedicated devices. People who use different tools instead of the right ones often end up disappointed due to wrong results. While wiring your racing car, always use crimps instead of pliers; otherwise, copper strands break in due time.

Crimps are designed to offer a perfect and smooth grip to the joined wires and cause them to remain joined for a long time. Moreover, most electricians prefer crimping over soldering because of the ease involved in the process. However, crimps should be used, not pliers, to avoid broken copper strands and short circuits.

Don’t be impatient

The last don’t of this section is to avoid being impatient and rushing through the entire wiring operation. Being impatient while wiring a racing car guarantees you bad results and defeat. You must lean back and review your diagrams, charts, tables, wire lengths, and tools. There is no need to rush through the project. Otherwise, you will only be running towards your disappointment. People rush through the entire process and make errors that are often difficult to track down.

Caption: Red Sports Car

Conclusion

Wiring a car may not seem easy initially, but it gets easier through consistent practice and helpful guidance. We offer standard harnesses and custom wiring harnesses. If you need help with wiring harnesses and cable assemblies, contact Cloom.