Cable engineers from Cicoil discovered that silicone rubber was suitable for building this ribbon cable assembly type in the 1960s. They merged many individual wires of identical sizes into the same assembly. Today, ribbon cables are easy to make, and their cost is low. You can see them on many peripherals in computers, printers, and other devices. Now, keep reading to learn everything you should know about ribbon cables.

Table of Contents

- What Is a Ribbon Cable?

- Ribbon Cable Assembly Specifics

- Building Ribbon Cables

- Custom Ribbon Cable Assembly

- Conclusion

What Is a Ribbon Cable?

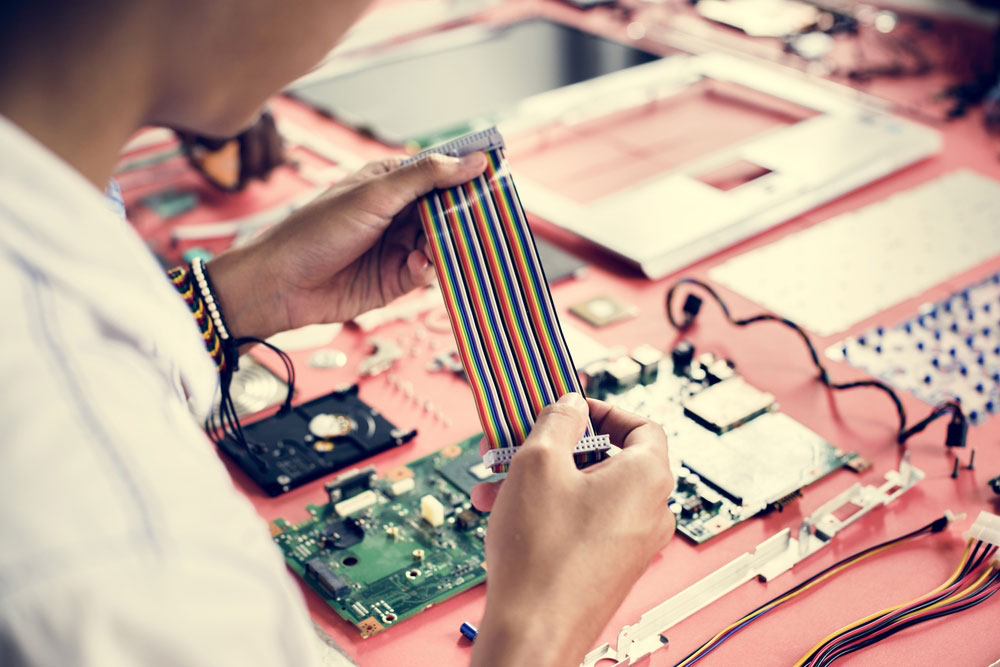

Caption: A ribbon flat flexible cable at the workshop

A ribbon cable has many wires on one flat plane. Now, those wires run parallel to each other. Therefore, these cables are flat and wide. While it’s a multi-wire planar cable, many use the term ribbon because of its appearance.

Ribbon Cable Assembly Specifics

The creators worked on product design to achieve an optimal ribbon cable assembly. Now, it’s the industry standard to consider the following three features when designing this cable.

Color-Coding

Caption: grey ribbon cable with wire for pin 1 marked red

Marking a cable’s edge with a red stripe is a common way of reducing the risk of reversed connections. The end with a stripe marking connects to pin one on the connector. That identification technique is okay for cables with multiple IDC connectors connecting to every wire. On the other hand, it’s less valuable if you need to terminate groups of wires or individual wires separately.

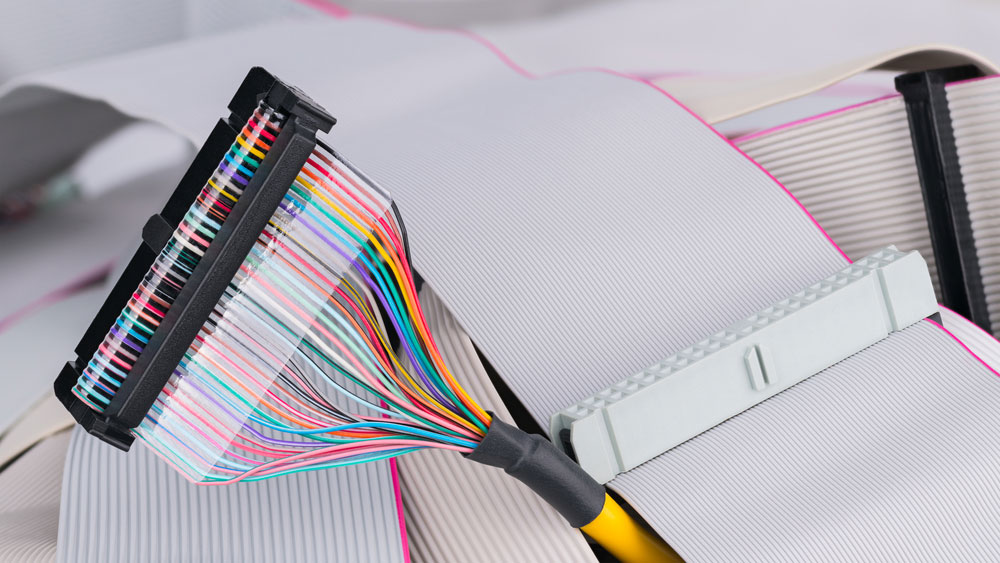

Caption: A colorful flat cable

A rainbow ribbon cable simplifies recognizing individual conductors in the assembly. The cable uses the same repeating color pattern as the resistor color code. That means brown goes to pins 1, 11, 21, and so on, and then red goes for 2, 12, 22, etc. Therefore, the rainbow ribbon type has a unique appearance, so this cable is also famous as a hippie cable.

Sizes

Ribbon cable specifics contain two numbers:

- Conductor spacing (pitch). The common spacing option is 0.05 inches (1.27mm). It provides a two-row connector with 0.1-inch (2.54mm) pin spacing. You’ll find these in internal connections, but also cables for floppy disk drives and older models of parallel ATA cables. The high-speed ATA interface cable has a pitch of 0.025 inches (0.64mm). Portable electronic gadgets like laptops can have an even smaller pitch of 0.3mm.

- The number of conductors. Most manufacturers stick to several pre-chosen options, including 4, 6, 8, 16, 24, 40, 60, 80, and some other values in between. You can go with a bigger width and remove a wire to fit your setup. For example, a 40-way IDC cable can become a 39-way unit if you need that option. Most manufacturers use 0.13, 0.2, or 0.32mm copper wires.

Connectors

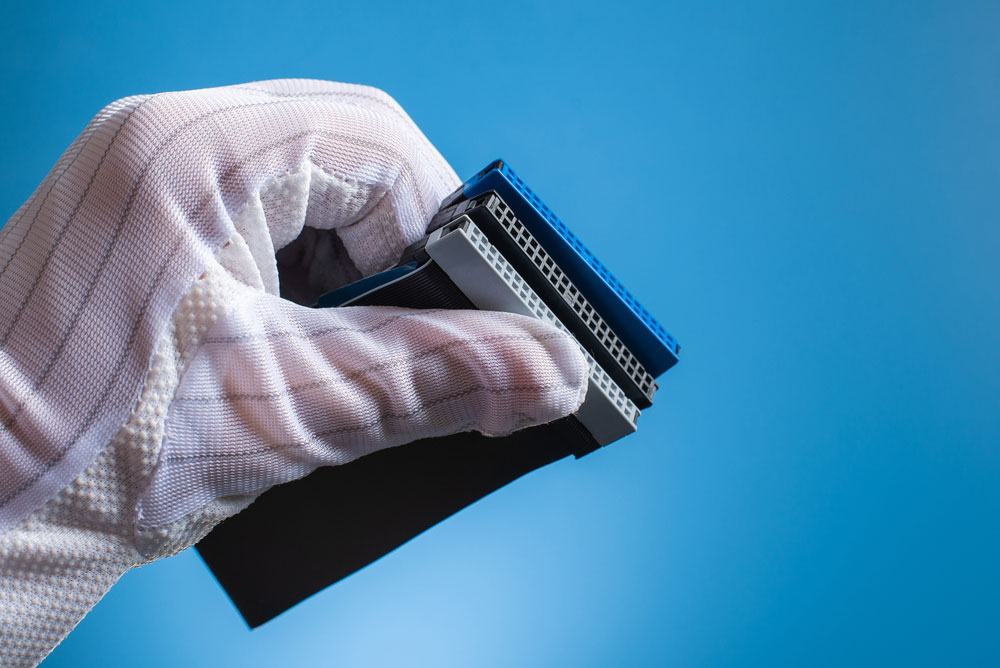

Caption: IDC connectors

Ribbon cables secure mass termination to IDC connectors where you force the cable onto with sharp-forked contacts. You’ll find this termination of both cable ends. On the other hand, custom cable assembly solutions could have IDC termination on one side. As for the other side, it would be a solder-bucket or crimp connection.

The main types of connectors for IDC termination include:

- BT224. The common name is an “IDC connector.” You find it on ATA cables. Now, they use header pins in a two-row grid for mating.

- D-subminiature connectors. The printer and serial ports are a wise fit for this setup.

- Micro ribbon. SCSI ports with 50 pins and some printer ports use this connector.

- PCB transition headers. Now, these are suitable for printed circuit board applications. While they have identical spacing as BT244, you can solder them into a PCB.

Building Ribbon Cables

Caption: A ribbon cable for a hard disk, floppy, or another drive

If you want to build this cable, you’ll need the actual cable and IDC plugs. It can be a hassle to make this setup. But if you’re going to try it, follow the steps below!

Buying Ribbon Cable Wire

First, you need the ribbon cable wire. Now, you can buy it in your local store or online. The stores sell it by length, so the provider might cut the size you need. Now, check the distance you’ll cover with the cable to determine how long it should be. Always give some extra room to ensure the length isn’t short.

You’ll also need to choose the pitch and conductor number. The standard pitch is 0.05 inches for expansion board connectors. As for the conductors, the plunger on the expansion board features eight pins.

Buying Ribbon Cable Connectors

Connectors come in different series, so consider the conductors and pins you need. You’ll find 0.1″ connectors to be a standard. However, it depends on your setup. It’s vital to ensure the connectors fit the assembly. That will ensure optimal performance and maximum longevity.

Assembling a Ribbon Cable

- Get the connector ready. You need to prepare the connectors for the cable, but note the jagged metal teeth on the lower piece’s surface. It’s sharp, so be careful not to destroy the cable insulation. Your idea is to make a gap big enough for the cable to go through it.

- Place the connector. Now, choose the pin header for plugging the connector. At this point, fit it loosely and keep a close eye on orientation.

- Prepare the cable. You need to cut the cable to the desired size.

- Choose the first pin. Use a red marker to place the “pin 1” position on the cable.

- Align the connector and cable and insert it. First, check where your board has the pin one mark. That’s where you connect this cable. Now, insert the cable into the connector. The width should fit precisely, but extend the cable a bit on the other connector end.

- Lock the connector. Keep the pieces in the desired position and remove the connector from the header. Then, squeeze the connector’s halves with pliers or a crimp tool.

- Connect the other end. Now, follow the steps above for the other cable end.

You might need a series of cables or don’t want to go through the hassle of making them. If yes, get a professional manufacturer to deliver cable assemblies, and wiring harnesses tailored to your needs.

Custom Ribbon Cable Assembly

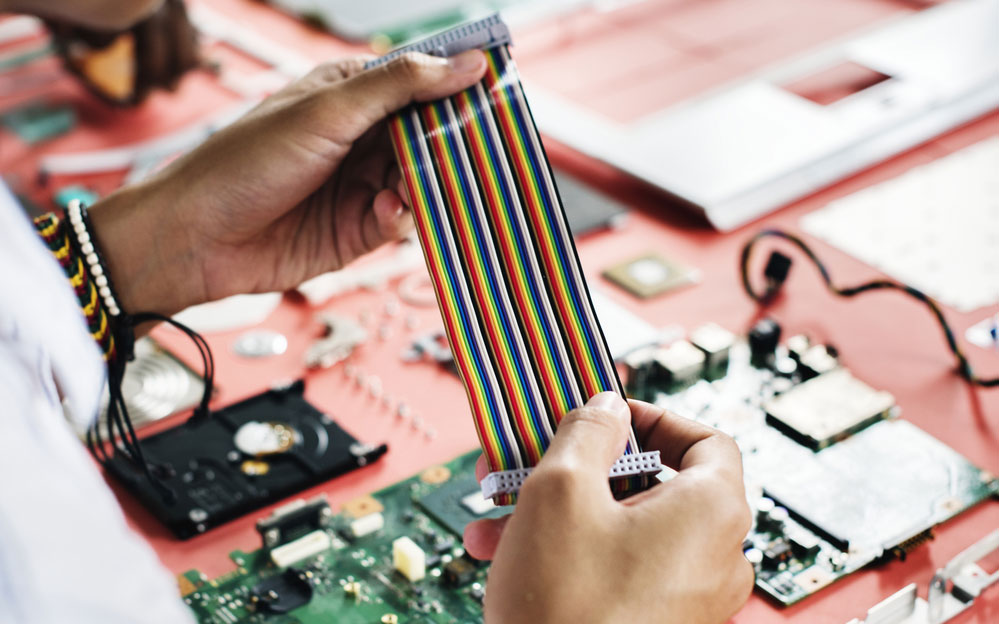

Caption: A closeup of a person holding a flat cable

A custom cable assembly brings many benefits. Apart from ensuring the desired quality, you get a cable that fits your setup 100%. Let’s check out some ribbon cable options!

Folded Flat Ribbon Cable Assemblies

If your product has limited space, folding the cable is wise. On the other hand, you’ll need a custom configuration. It’s how you ensure the cable fits your design. For the maximum quality of these cables, you need a reliable supplier. They should have optimal manufacturing equipment to fold the cables.

Color-Coded Ribbon Cables

Rainbow ribbon cables use insulated conductors in a parallel setting. However, it’s possible to go with twisted pairs. You’ll need a repeating flat termination section at specific lengths.

If you have an edge-marked cable, you’ll find the first conductor attached to the “pin 1” has a stripe. The center spacing or pitch decides the color of the edge marking. Therefore, you can find the desired connector easily.

Multiple Connectors on One Cable

Now, why limit IDC plugs to cable ends? You can attach them anywhere on the cable. Therefore, you can use one cable to connect many boards. For example, here is how to use one cable to join two flasher panels:

- First, a cable plug at one end goes into the output controller.

- Now, use the other cable end to plug the connector into the flashers on the cabinet.

- Finally, place a connector somewhere in the cable’s center. Plug it into the cabinet’s back flasher panel.

Flexible Flat Cable

Flat flex cable assemblies are thin, making them suitable for electronic devices. Furthermore, you’ll see them in high-density products like smartphones and laptops. The best way to describe the FFC is to say it’s a smaller ribbon cable. Unlike other ribbon assemblies, this one has to be flexible. Therefore, the base is a flexible plastic film.

Caption: 35-conductor flexible flat cable

Conclusion

Ribbon cables are versatile since they vary in pitch and number of conductors. These cables have many uses, but it’s all about finding the proper assembly. At Bloom, we have years of experience designing cable assemblies and wiring harnesses. We use premium equipment and materials to deliver cost-effective custom solutions that exceed your expectations. Don’t hesitate to contact us to discuss your cable requirements!