While setting up an electrical device, manufacturers always designate a safe path for the electrostatic discharge. This way, the electrical current can reach the ground without injuring people or destroying the system. For this purpose, you can use ground instruments available to you. You can find these critical safety devices in many variations. For instance, you can have aluminum, steel, or copper-plated flat or tube wire.

Table of Contents

- Braided Ground Strap Specifications

- Ground Wires Specifications

- Ground Braided Straps vs. Wires and Cables

- Conclusion

Braided Ground Strap Specifications

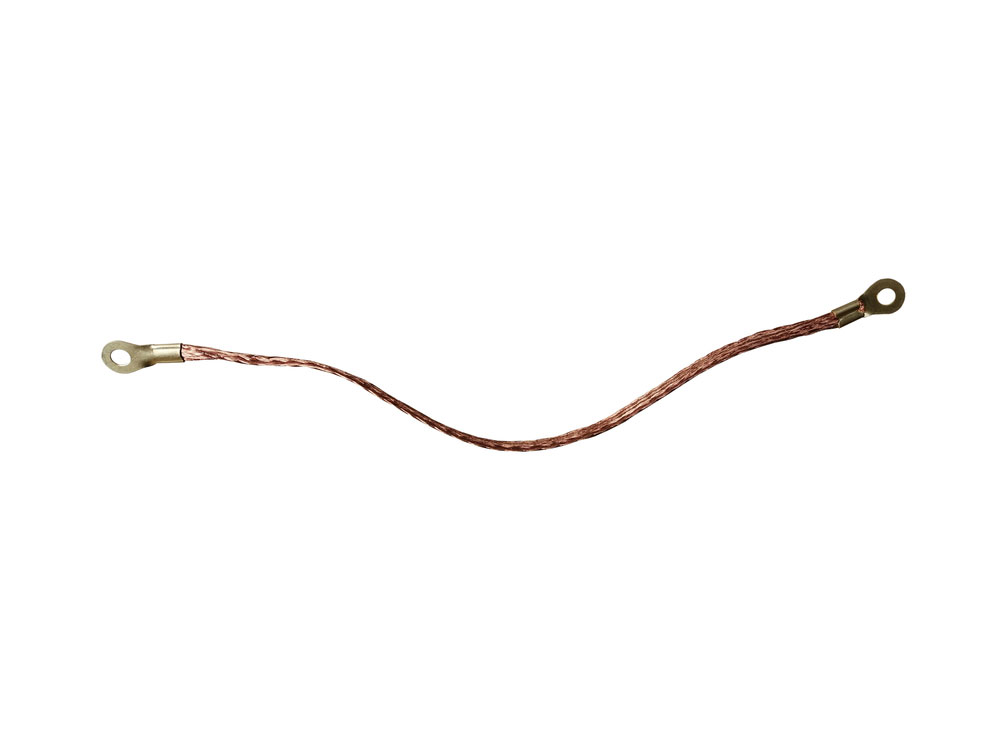

To form a braided ground strap, the makers interlace multiple strands of metal wire that should be flexible. That way, they can achieve a much stronger structure, are thicker than the non-interlaced wires, and resist twisting if present under load.

Caption: Grounding wire in Car Chassis

Take a 4 AWG (4 Gauge) battery cable and twist it under load. You will observe that it is easier to break than a braided wire that resists breaking. In addition to mechanical strength, you can adjust the braided ground straps to smaller areas, such as the opening or panel of the equipment. Hence, it is space-efficient as well.

While manufacturing, they flatten the ground straps first present in tabular form. That way, they achieve an increased surface area for more excellent resistance.

If you talk about the material, a flat braided cable is made of tinned copper wire to which they use metal connectors as terminals. Here, the width and length are key wire measurements that affect the performance of the wire.

Moreover, since the copper dipped in tin provides more excellent electrical conductivity, corrosion resistance, and solderability, you will observe that most straps are made with tin copper. But, if you require a RoHS-compliant application, you can also get straps with lead-free solder. Additionally, you can also choose between different hole sizes and termination orientations.

Typical applications of braided straps are:

- Attaching one radio chassis to another for grounding the car system

- Connecting swinging gates or doors to the grounding systems

- Attaching all the equipment with the single ground point

Ground Wires Specifications

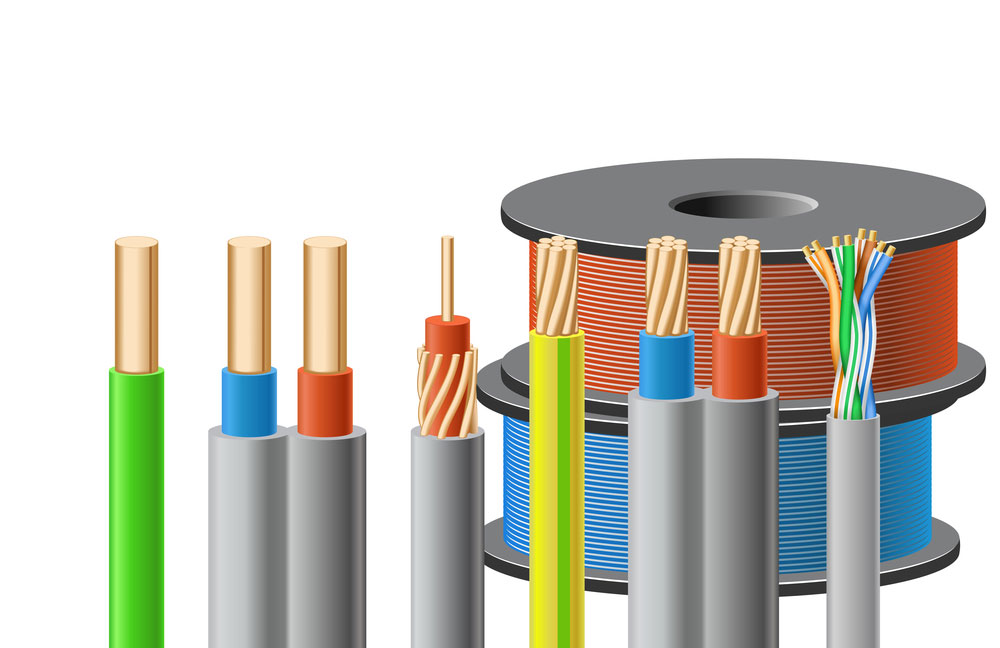

On the other hand, ground wires are of two types, stranded or single. A solid ground wire comprises a single conductor wire covered with insulating material. At the same time, the stranded ground wire has multiple thin wires twisted ( not in the shape of a braid) together within the insulator layer.

The companies typically use copper to manufacture the wires since it has good conductivity and is durable. Also, the design of the simple wire makes it easier for the engineers to install and maintain the connection. As the cables are available in different sizes and insulation levels, you choose the critical usages.

Caption: Different kinds of simple wires

However, as the shape is round and the wire has a lesser surface diameter, you might not use it with low impedance connections.

Typical applications of Ground wires are:

- Grounding of amateur radio equipment ( you can use solid wires of 10 AWG)

- Basic lighting protection ground (you can use stranded wire of 2 AWG or up)

Ground Braided Straps vs. Wires and Cables

Now, let’s have a clear comparison between the two kinds.

Functions of Braided Ground Strap and Ground Wire

Take an example of the vehicle’s machinery. Battery cables are stranded cables with jackets and a few thin wires. The grounding straps have more wire strands but are smaller in diameter. That way, it can support higher heat dissipation, higher amperages, and more excellent durability.

The function is the same whether the braided ground strap connects the engine block to the chassis or the engine block to the battery’s negative terminal. That is repeated movement and vibration.

Caption: Electrical Wire installation

In such places, the wire cable can fatigue with constant flexing. However, the braided wires do not break down and are ideal for such areas. That is the reason why braided straps are preferred in the manufacturing of planes and trains as well.

Types of Braided Ground Strap and Ground Wire

You can find braided grounding straps in standard as well as custom configurations. It can vary based on length, width, sizes, styles of terminals, and whether it is lead or lead-free solder.

On the other end, the wires are of two kinds, solid or stranded. These are available in varying wire gauges that tell you how much electricity the wire may safely carry. Moreover, some ground wires may use a bare conductor, whereas the others can have to condition electrical insulators.

Material of Braided Ground Strap and Ground Wire Material

Whether the strap and wire differ, both use conducting materials such as aluminum, copper, tin copper, stainless steel, silver-plated or nickel-plated materials.

According to the National Electric Code (NEC), a ground wire can be with insulation or bare. If it has insulation, it should be green or yellow. Mostly, the makers insulate wires with plastic or rubber. However, in some cases, the insulation can be fiberglass.

Ground straps can have insulation on top of them. But since they might have a lot of mechanical stress on them, bare braided straps are a good option for such situations.

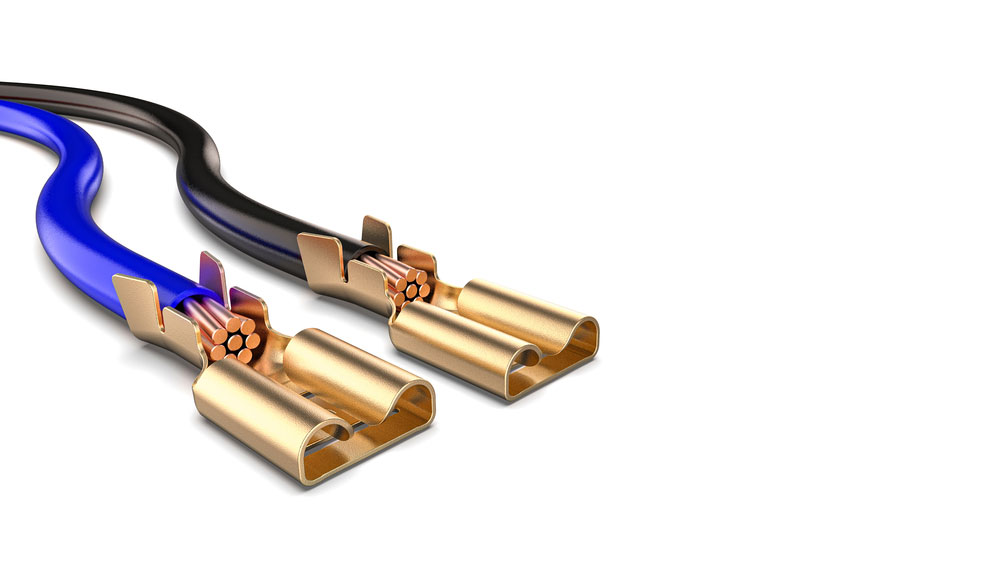

Caption: Insulated copper wire for cars

Electrical Safety Application of Braided Ground Strap and Ground Wire Material

You can see Braided straps in aircraft, trucks and cars, heavy machinery and equipment, generators, power suppliers, transformers, and other rich applications. Hence, using the correct type of battery ground strap in a vehicle or a dryer ground strap for home appliances will provide a path to the electrostatic discharge.

Ground wires also have the same intended use, but it is present in the outlets and electronics instead. Hence, the strap is for the car’s engine, whereas the wire is for the car’s sound system.

Caption: Electrical wires with brass connectors for automotive use

Conclusion

Braided wire straps provide greater surface area and are much more flexible than ground wires. While both use the same conducting material, their use is different. Hence, the straps are for places with a lot of mechanical stress. If you use ground wires in such sites, they will most likely breakout-causing the system failure.

Here at Bloom, we offer an Automotive wiring harness, so your connection is with attention to detail. To avail of our services, contact us now.