Many characteristics of copper make it a perfect pick for audio cables. Besides, several companies also use OFC or oxygen-free cables in theatre music and film reproduction connections to enhance audio performance. Why? In the following article, let’s discuss using the copper audio cable and their different types.

Table of Contents

- How do you choose copper over silver?

- The types of copper conductors:

- Are Oxygen-Free Copper Cables Worth the Added Cost?

- Conclusion

How do you choose copper over silver?

Let’s start a debate between the two.

Copper Audio Cable: Copper vs. silver: Performance

You must understand that warm copper harmonizes better with semiconductors, and silver, due to its cold nature, harmonizes with valves (warm nature) better. When you combine both warm nature cable components, the sound you get is warmer and less dynamic.

Also, silver and copper only harmonize in a good way together if wired parallel. Don’t think that you will get the best of both when combined. Instead, the resulting sound will have dissonance between both conductors.

Copper Audio Cable: Copper vs. silver: Cost

An ounce of silver costs ten times more than copper. So, it’s evident that cables made from silver will come at a higher cost. You may cut the price by decreasing the amount of silver employed in the cable. However, you must know that the amount of silver is directly related to the absence or presence of mid-bass. So, tempering with the silver quantity will lead to poor sound quality. Whether high cable prices justify the sound quality depends on the expectations and requirements of an individual.

Copper Audio Cable: Copper vs. silver: Other features

- Origin and age (which of them is new or old).

- Conductor geometry (flat, thick, or round)

- Insulation of the conductor (dielectric material, the thickness of insulation, and distance

- Storage and treatment conditions

- Conductor purity

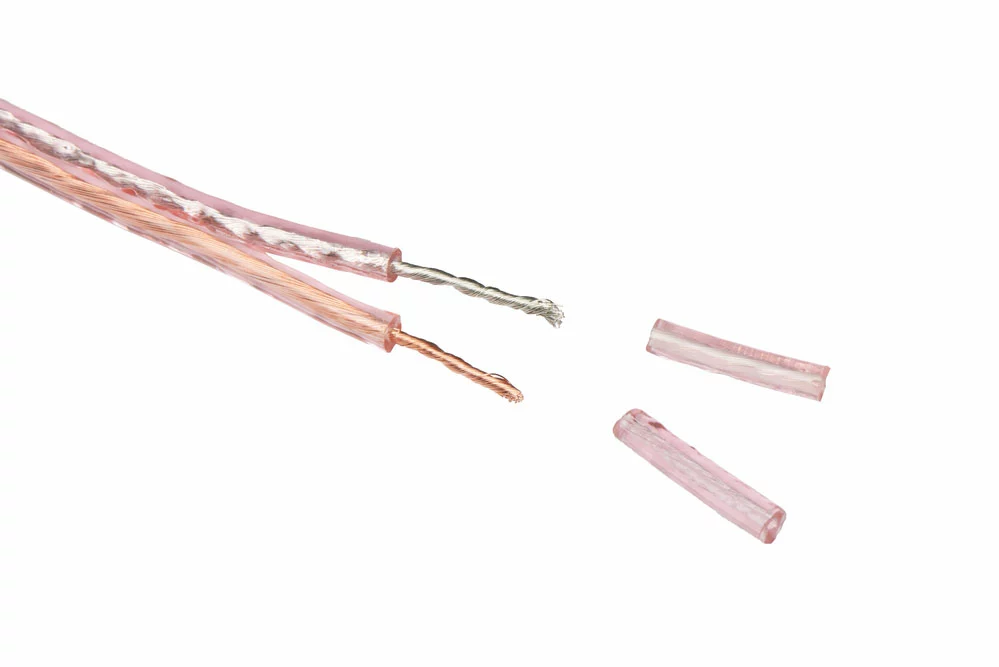

Caption: copper speaker wire

The types of copper conductors:

Some conductive materials like OFC, OCC, and LC OFC show better sound fidelity than TPC.

Copper Audio Cable: Unprocessed copper- tough pitch copper (TPC)

Tough-pitch copper or unmachined copper is commonly used in low-cost audio cables. The cable manufacturers first melt the TPC, give it a cylindrical shape and then allow it to cool. After this, makers repeatedly engrave the wire to give it the required diameter.

Tough-pitch copper has around 300-500 ppm of oxygen and other types of impurities, and this quantity is too much for crucial audio applications. If you use this copper for power cable or speaker wire, there will be no fine details in sound, and you will get an opaque audio system. The PVC insulation also affects the sound quality in these standard audio cables.

Copper Audio Cable: Oxygen-free copper (OFC)

Gradually manufacturers learned that the copper quality and its treatment process affect the audio quality. After this thought, Oxygen free copper was designed in Japan around 1975.

OFC copper follows an extrusion process for manufacturing. As the production occurs in an inert atmosphere (free of oxygen and other gases), the silver oxide content reduces to 10 ppm compared to 300-500 ppm in TPC. Also, the copper’s conductivity increases between 0.5% and 2% higher than the TPC. As a result, when manufacturers design audio cables from this copper type, you get high quality. The purity of the copper delivers clean and clear sound as fewer border areas lead to sound degradation.

Copper Audio Cable: Linear crystal- Oxygen-free copper (LC-OFC)

Hitachi developed the production process of LC-OFC to reduce boundaries between nearby veins and crystals. Manufacturers reheat the copper wire after extrusion to remove impurities from the crystal boundaries, as copper crystals have longer grain. Compared to the 4mm long grain in TPC and OFC conductors, the grain length is 130mm in LC-OFC conductors.

Ohno Continuous casting copper

This variety got its name as professor Ohno from the China Institute of technology worked hard to develop his patent method to get a grain-free copper conductor.

During manufacturing, when a pure metal becomes solid, its crystals form a geometric pattern on its boundary that radiates from the core. The size of the crystals may vary based on the heating frequency, and these crystal boundaries create a non-linear resistance in the electric current path.

In the Ohno continuous casting method, manufacturers reheat the extrusion and release the molten form of copper from the mold. As a result, it gradually pushes the crystal or granules along the conductor length resulting in a monocrystalline structure. You must know that there is nothing like 100% copper. There are always some boundaries of impurities, but here these boundaries are insignificant. In this process, the crustal reduces to 0.3mm in a copper conductor of 125m in length.

Due to insignificant boundaries, there is no hindrance in the electric current path, and you can get better details and more information delivered to your device.

Silver plated copper

In silver-plated conductors, you get good-quality high-frequency dynamics. You must compromise bass quality and performance if you think silvered copper gives you opaque tones. Listening to a silver-plated copper cable for a long time leads to irritation and fatigue. Avoid using two materials of different resistance in speaker and signal cables.

Caption: acoustic sound cables

Are Oxygen-Free Copper Cables Worth the Added Cost?

One reason you get better sound with oxygen-free cables is that copper has crystalline nature where each crystal has its specific boundary, which electrons cross. When you take pure electrical grade copper, it has 1500 crystals per foot which audio signals must cross. When electrons pass through the impurities, they result in phase shift and distortion, thus degrading sound quality. OFC pulls the knots tighter, thus reducing the hurdles for the electrons. Further, the electrolytic refining process removes other impurities from the copper, especially iron which may cause resistance.

However, Roger Russel, the former director at McIntosh Laboratory (in acoustic research), said that Oxygen Free Electronic (C10100), having an oxygen level of 0.0005%, is only one percent better in conductivity than C10200. The conductivity rating of C10100 is almost similar to other C11000 grade copper, which is irrelevant in audio applications.

Another advantage of oxygen-free copper is that copper is susceptible to corrosion when exposed to air. In oxygen-free copper, the chances of corrosion are less due to less oxygen, and it is more durable and long-lasting.

So, the OFC is preferable because it delivers audio signals consistently and has excellent reliability, longer life, and better performance.

Caption: speaker wire on a reel

Conclusion

It’s the conductive material required for good sonic characteristics in audio cables and the other elements that result in a good quality speaker cable. For example, you need to consider propagation speed, dielectric choice, construction of connectors, and the type of conductor.

You can get some high-quality audio cables and other cable assemblies from Cloom. We are a leader in producing superior-quality wiring harnesses and cable assemblies of all types. Contact us for more information.