As you are working in automation, the type of cable used to carry the load is critical for the smooth operation of moving robotic or automated equipment. However, a cable isn’t going to do its job well enough to withstand constant abrasions and rotate only if it is flexible. Here, the constant motion of machinery can quickly degrade cables, leading to frequent failures and expensive downtime. Hence, you might need to look into a proper wire rated for such applications. According to most manufacturers, the cables suitable for such applications are “flexible cables.”

Table of Contents

- What are Flexible Cables?

- Construction of Flexible Cables

- Requirements For flexible Cables

- What is the difference between flexible cable and flexible cord?

- Conclusion

What are Flexible Cables?

Flexible cables are made up of hundreds of conductor strands or fine wires that you can bend millions of times. Moreover, it can retain its properties without breaking or losing the data transmission capacity or current movement.

Generally speaking, the motion of flexible cables can be either of three ways.

Bending:

You might bend the cable hundreds of times

Torsion:

In some cases, you might twist the cables longitudinally. Due to such torsional movements in wind turbines, this situation occurs. However, these cases are rare since twisting also comes with bending.

Winding and Unwinding:

The instance, when you unwind the cables from big reels. For example, in stage performance, where you will wind it for the time being and then store them for later use.

Aside from the braided conductor class, another feature that distinguishes a flexible cable from a less flexible one is the stranding. To grasp this, consider that thicker areas alternated with thinner areas as you braid closer together in a hair braid. Twisting the hair makes it thicker. In “stranding,” copper strands do something similar.

Manufacturers twist the thin metal wires to improve flexibility – if all strands and cores become parallel, it will extend the external copper cabling and compress the inner ones when the cable bent. It would stiffen the cable. The length of the lay controls thickness and versatility. The cable is thinner if it is longer and has less twist.

Cables that move a lot have sliding support that helps the components move as smoothly as possible. They also keep the cable round. For cables going through glands or connectors, leaks occur if you do not work properly around the sheath. Moreover, sliding supports can be fine plastic strands that slide between the cores. You will wrap it in polytetrafluoroethylene film fleece to make sliding easier, especially under torsion.

Caption: Optical Cable with hundreds of fibers

Construction of Flexible Cables

You can divide flexible cables into two types: conductors stranded in layers and bundled or braided conductors.

Stranding in layers

Because it is easier to make, stranding in layers is cheaper because it is easier to make. The cores wind strongly and leave several strands around the center. Then, a tube-shaped jacket of extruded plastic wraps them from the outside. For shielded cables, you will wrap fleece or foil around the cores.

However, when the cable core bends, the inner radius gets smaller, and the outer radius gets bigger as the wire core moves since the manufacturers have designed it that way. At first, this works well because the material is still flexible enough. But, the material can wear out and cause permanent changes. Thus the cores move and start to make their areas of compression and stretching, which can lead to a “cork-screw” form and, eventually, core breakdown.

Stranding in bundles

The second method of making flexible cable is by braiding the wires around a strainless center rather than layering them. This method makes sure that each conductor has the same radius for bending.

Every core quickly moves from the inside to the outer layer on the cable bending point. Because of this, no single core gets compressed inside or stretched near the front of the bend. It lowers stress overall. Moreover, it fills all the straps around the center and prevents them from coming apart. The result is a dynamic cable that is usually stiffer than a regular cable but lasts much longer in situations where it has to bend constantly.

Use within cable carriers/drag chains.

You can use flexible cables for various tasks because of their adaptability. However, you must cover them with cable carriers or drag chains to protect the flexible cables while building projects. It not only ensures the safety of workers but the well-being of cable as well.

So, if your cable is damaged, it will almost certainly be expensive to have it repaired. Additionally, the risk of injury increases if you leave the wires dangling in the air or running along the floor without an extra layer of protection. Hence, it is important to use the cable carriers over the flexible wires.

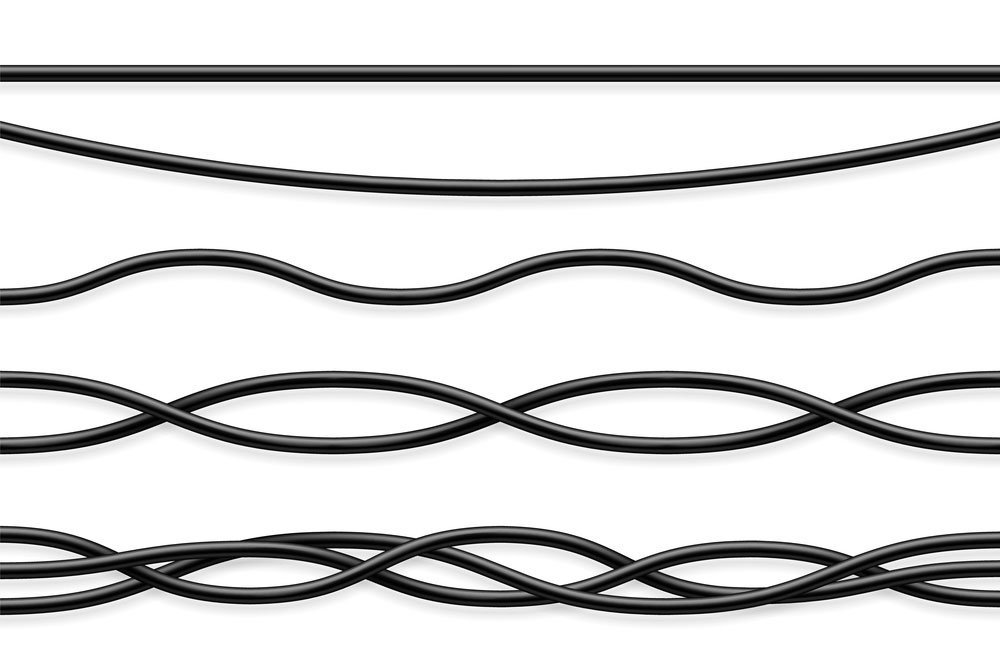

Caption: Black electrical cables with different flex capacity

Requirements For flexible Cables

Following are some requirements while installing the cables in flexible environmental conditions.

- You should use flexible cables in operating equipment that do not have rigid requirements.

- As per cable length, you need to cut the flexible cables so that they can respond to the short circuit situation. Also, it should be long enough to tolerate the risk of physical and mechanical damage.

- Multi-conductor flexible cables must be protected from permanent bending, abrasion, stress, and tight bends. Especially at the point of entrance in port connectors, minimal stress should be applied for better electrical performance.

- Additionally, you should avoid attaching the special cable to any equipment unless you have wrapped it in mechanical protection or rated it for permanent installation.

- You should not place flexible cables under carpet or floor covering since they can heat up and cause the insulation to burn. Moreover, the foot traffic can also damage the flex cables.

- Flexible cables should not be used under high temperatures. Additionally, these cables are also not suitable for freezing temperatures.

- Due to its characteristics, certain ratings will determine the short periods of continuous usage. However, flexible cables are not suitable for permanent installation outdoors.

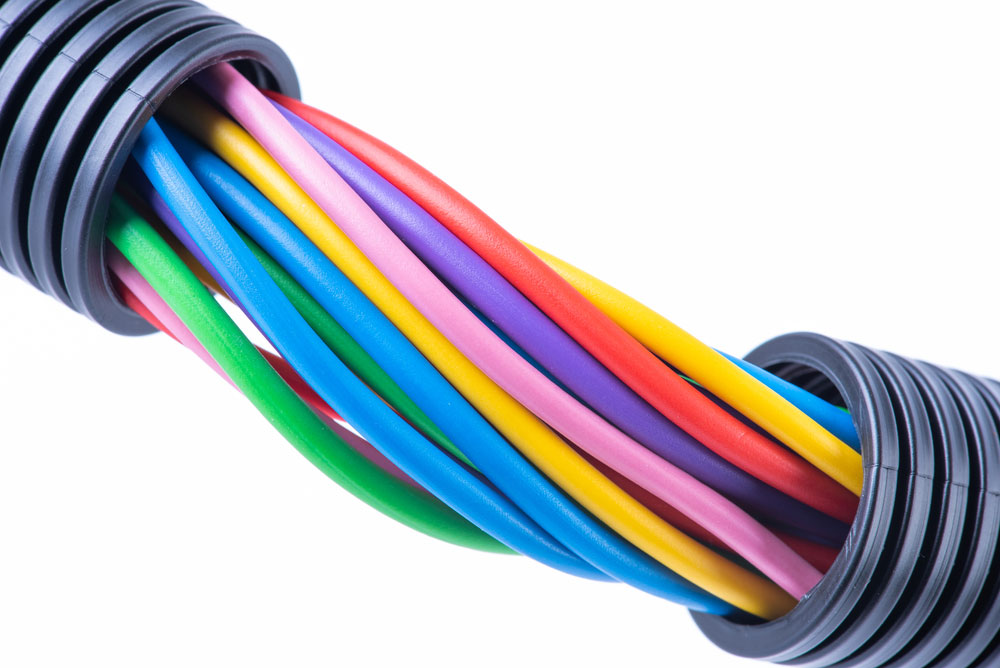

Caption: Multiple thin insulated wires inside a protective cover

What is the difference between flexible cable and flexible cord?

Flexible Cable, Flex Cable, or Flexible Cord; you might mix these terms as companies use them interchangeably. However, they do have some differences in them.

As we talk about flexible cable, Flex Cable or flexing cable is a wire with hundreds of thin strands. Moreover, it is pliable and can tolerate a certain amount of flexing life cycles in its application time. However, another variation of flexible cables is called continuous-flex cables. Continous-flex works much better than simple cables in machinery used for control, data bus coaxial, fiber optic, power, and robotic applications.

On the other hand, Flexible Cords (also called Portable cords or service cords) connect the electrical devices to the power source. You can use them for temporary connections or permanent installation at your workplace. Moreover, they might have plugs available on one side to mate with the power plug and form strong connections in flex applications.

Several types of multi-conductor flexible cords are available:

- Type W Cable -8 AWG, 2000 VAC

- Type SOOW – 18 to 6 AWG, 600 VAC

- The Type SEOOW – 18 to 10 AWG, 600 VAC

- Type SJOOW – 18 to 10 AWG, 300 VAC

- Type SJEOOW -18 to 10 AWG, 300 VAC

And commonly used designations for flexible cable power cords include:

- SJ = Junior Severe Service (300-volt cords)

- S = Severe Service (600-volt cords)

- OO = Oil-Resistant Interior Insulation and Oil-Resistant Outer Jacket

- E = Thermoplastic Elastomer

- W = Weather and Water-resistant

Caption: Bundles of network cables

Conclusion

Flexible cables can tolerate twisting and turning. Moreover, they can be made with several methods, each with specific ratings and usage. However, as you apply them in a real environment, you have to check for the ratings to which it can comply. Also, you should not install them in places where the surrounding causes permanent damage to the cable. Here at Cloom, we offer wiring harnesses and cable assemblies with attention to detail. To avail of our services, contact us now.