You may have heard of hardlines. If so, it’s probably from an action flick. Usually, you’ll see a scene where someone yells, “cut the hardline.” Sounds fictitious, right? Well, that’s the point. Today, hardlines are non-existent, except in such movies and several other areas, not to mention hardline coax connectors. But there was a time when the hardline was king. Now, let’s have a look.

Table of Contents

- What is Hardline Coax?

- Choosing the Right Hardline Coax Connectors

- Installing the hardline connectors

- Conclusion

What is Hardline Coax?

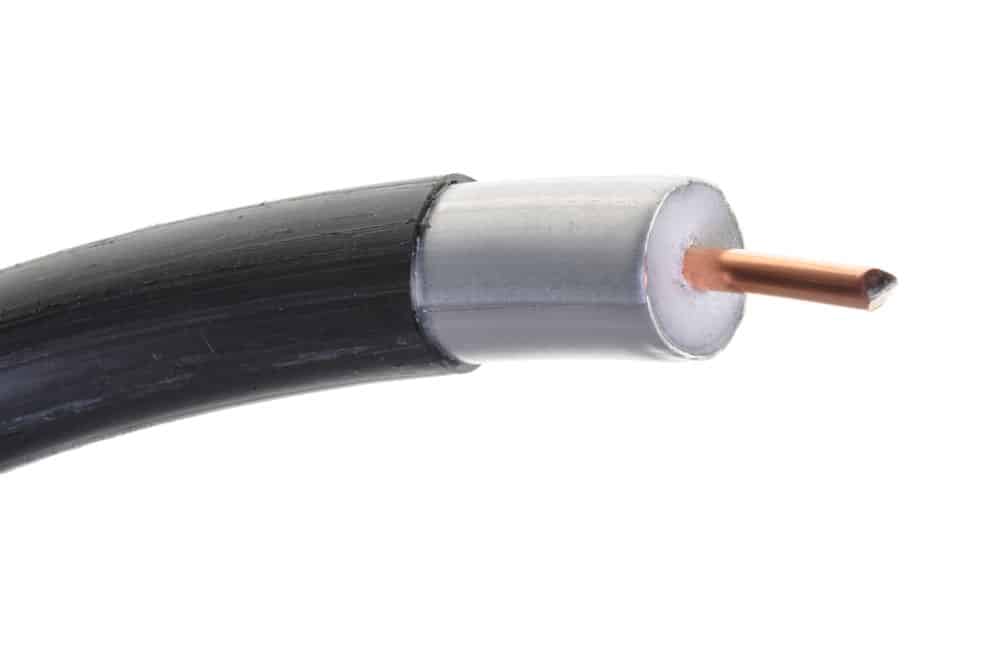

These cables work similarly to regular coaxial cables but are much larger. Utilized in broadcasting and other forms of radio communication, they have solid shielding, high power handling, foam dielectrics, and low signal loss.

Over the years, the properties of hardlines have changed. For instance, the shielding is either copper, silver, gold, aluminum tubing, or a blend of these metals. Other changes include variations between the outer and inner diameter of the core conductor, shied, and even the spacing between rings.

Choosing the Right Hardline Coax Connectors

Connectors made from highly conductive materials such as tarnish-resistant silver or gold terminate coaxial cables. Every hardline requires a connector that fits it mechanically and sustains constant impedance through it. This has made finding suitable hardline coax connectors a real challenge.

For example, coax connectors for lines with spiral shields fasten onto the cable. Those with annular shields have connecting components that secure the connector to the cable. So before selecting the connector, check what kind of hardline you have. Besides that, most connectors are reusable, so don’t rule out getting second-hand ones from reputable dealers. That said, you have to thoroughly check the connector to ensure it is still in good working condition.

Installing the hardline connectors

Given these connectors’ technical and sensitive nature, it’s best to let only qualified personnel install them. Otherwise, bodily harm or damage to the equipment may occur. Anyway, let’s look at how to make the installation easier and faster.

1. Gather all tools

The first step is getting tools together. Hardline connectors vary, and as such, the tools needed will differ. For instance, QR coax cables require a different preparation technique than P3s. As you are gathering your tools, you want to ensure they are in proper working condition. A dull blade can leave score marks on the conductor core or outer sheath. This can, in turn, cause weak spots resulting in transmission issues.

2. Prepare the cable

Make a clean square cut at the end of the cable, where you will attach the connector. Don’t distort the cut in any way; make sure to clean off any flooding material left on the outer sheath. Also, ensure the conductor core is clean and debris-free, meaning there’s no dielectric residue left. You can use a cable core cleaner to remove the dielectric or your fingernails. Do not remove the residue using another object, such as a knife, which will damage the core.

3. Trim the conductor core

You need to trim the core to the right length before connecting the conductor. If it’s too long or too short, it will cause transmission issues. Use the cut marks provided by the body of the connector to determine where to cut. Using pliers, cut halfway through, rotate the pliers 90 degrees, and complete the cut to make a chisel point.

4. Double-check the connector’s pin length

Cutting the stinger pin correctly is the easiest way to ensure proper signal transmission and network performance. With the right pin length, you can make connections more easily in the equipment. Measure and mark the connector pin, then using the equipment cut mark as a guide, make the cut.

5. Make sure to tighten the connector

A common reason for installation errors is not tightly securing the connector to the cable. Securing it hand tight will only hold for a while but fail later on. Always ensure you utilize the right tools to tighten the connector to the cable body. Else you will have a bad installation that will need you to come back and correct it later on. That said, you also don’t want to tighten the connector too much and damage the cable.

Conclusion

All in all, hardline connector installation requires a great deal of care. That is why you should hire qualified personnel to help you out. Do you need help? We are experienced and will ensure everything is set upright.