There are many cables and wires present in the electronic industry for different applications. However, every cable is not suitable for low-voltage, internal wiring applications. For that, hook-up wires or lead wires are the best options. However, it would help if you looked into some factors while choosing the best hook-up wires. So, let’s dig into it.

Table of Contents

- What are Hook-up Wires?

- Certifications of Hook-up wires

- What to Consider When Buying Hook-Up Wire

- Conclusion

What are Hook-up Wires?

Hook-up wires, lead wires, or appliance wires consist of a single conductor wiring covered with different insulation materials. You can use these wires for the internal wiring of your appliance. So, you will find these wires in different homes and industrial appliances like switchboards, panels, power and control circuits, rectifiers, transformers, and motors.

Here are some highlighted features of electronic hook-up wires:

- Most hook-up functions require these.

- The specific high temperature or high thermal conductivity of hook-up wires facilitates high-temperature applications.

- The extruded material makes the hook-up cables with tough exterior and flexibility.

- The insulation can be color-coded and striped.

Caption: Hook-up wire with multiple thin insulated wires

Certifications of Hook-up wires

You can identify the cable in various ways depending on the type of wiring used. For example, multi-conductor cables utilize the made material to explain their construction and wiring products. Wire hook-ups are no exception and have a significantly broader range of designs than other categories. Different certifications help to distinguish these various goods.

CSA Hook-Up Wire

The most prevalent designations for hook-up cables are CSA and UL. Although these terms may refer to the same product, they have different meanings. Thus, Hook-up wires specified by CSA include popular CSA TEW, CSA REW, CSA SEW models, and the CSA-specific Type SIS. The Canadian Standards Association (CSA) established these special designations. However, it may require additional permissions due to the application type and area. CSA FT-4 and CSA AWM are two examples.

UL Hook-Up Wire

Every hook-up wire has UL and CSA approvals, but the manufacturers will often rate the UL for specific gauge sizes, whereas the CSA has one rating for all gauge sizes of that construction’s specific gauge. It’s uncommon for UL certification to have the same voltage rating as its products, but if not, it’s usually lower.

Because of the wide range of countries that utilize the UL designations, electrical wiring designations issued by that organization differ from those issued by the Canadian Standards Association (CSA). Though it’s nearly equivalent to CSA, you can use UL for lower voltage applications, making it a common certification.

Mil-Spec Alternatives

Mil-spec wiring items are mistaken for hook-up cables. However, this isn’t the case. Hence, if the UL or CSA constructions are unavailable, these related constructions can be an alternate option. Thus, the only difference between these options is that the hook-up or military spec wires do not hold certification for only certain application circumstances, so these choices are identical in specifications.

Caption: CSA/UL & Mil-Spec Alternatives

What to Consider When Buying Hook-Up Wire

You should consider:

Conductor-Related Specs

- Material: Most of the time, the conductor inside hook-up wires is copper, the most popular conductor material. For example, copper doesn’t rust and is a good conductor of heat.

- Size: Most manufacturers use American Wire Gauge (AWG) to measure the surface area of a wire in the U.S. When the gauge number is greater, the diameter of the wire is small. Moreover, a thicker diameter means that a wire can handle more current and has less resistance. And the AWG size of most hook-up wires is between 10 AWG and 28 AWG.

- Solid or Stranded Wires: Stranded conductors are a group of thin wires that twist around each other, making them easier to bend than solid wires. On the other hand, the solid wire comprises a single core wire covered with insulation.

Jacket Materials

Protecting the wire from damage and allowing current to leak out of the conductor is one of the primary functions of the jacketing materials. Thus, you can use Polyvinyl Chloride, silicon rubber, neoprene, and other materials to make jackets for hook-up cables. For example,

- You can use Insulated thermoplastic or PVC hook-up wire-like UL1015 (MTW) in panels and meters to conduct internal wiring.

- For switchboard wiring and industrial control panels, cross-linked polyethylene, or XLPE insulated hookup wire, is commonly used.

- In addition to its uses in machine tool wire (MTW) applications, thermoplastic shielded with nylon sheathing hook-up wire (TFFN) is also used in appliances and fixture wire material.

- Additionally, Teflon insulation (PTFE, ETFE) or flexible Silicone is best for high-temperature applications. Many configurations are available, ranging from simple to complex, that can withstand temperatures of up to 200°C and even more. Moreover, larger gauge widths and higher voltage levels are often required in these less-common applications.

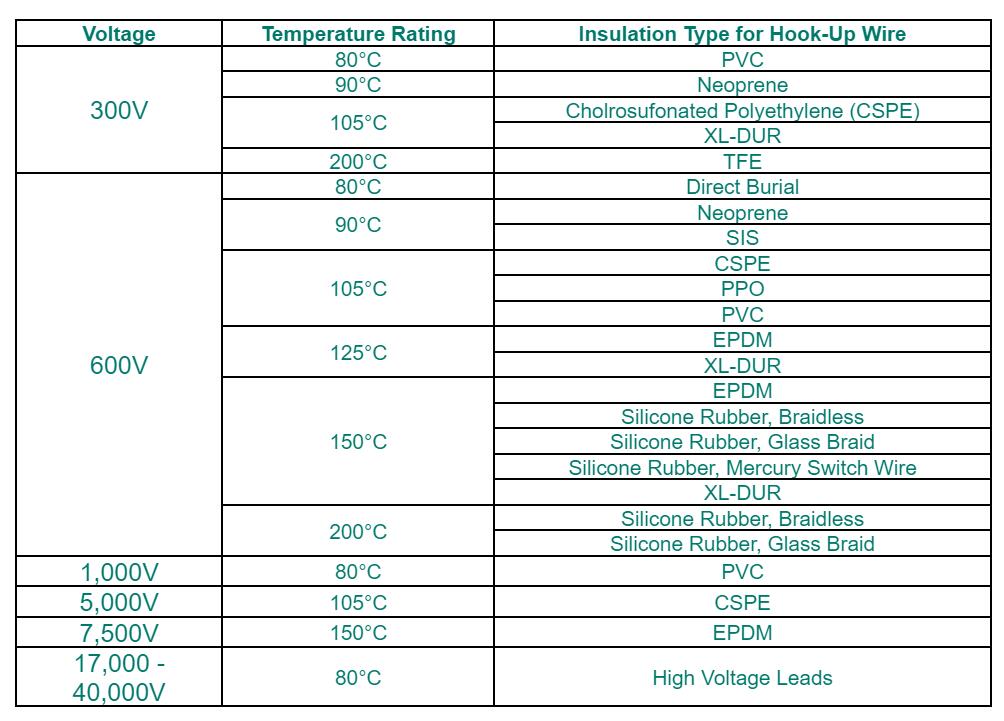

Voltage

If you need a wire for applications <1kV, a Hook-up wire is the best option. The voltage rating is another important aspect that you have to look into while choosing hook-up cables. Due to voltage rating, you will also decide on the insulation thickness and types.

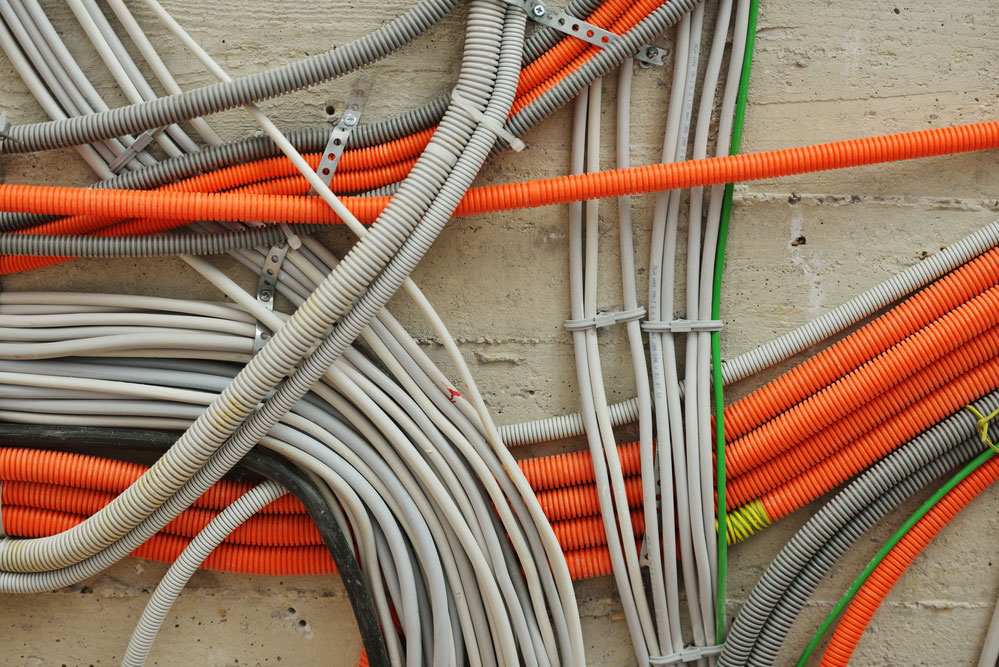

Caption: Insulated hookup wire reels

Conclusion

Hook-up wire is an insulated conductor with insulation material. It is necessary for the internal wiring of appliances. And you need to choose a good lead wire based on different factors. Here at Bloom, we offer wiring harnesses with proper lead wires, so your connection is made with attention to detail.