The United States military has a set of MIL-Spec (Military Specs) standards. They are crucial for any electrical device that faces harsh elements like chemicals, cuts, or high temperatures. Among these elements is the mil-spec wire that conforms to the army safety standards. Hence, manufacturers use these standards for wiring loom and cable assembly to determine the type of material and method of the group. Furthermore, as the wire is essential in harness making, you must manufacture it with extra care. Read along to get a deep insight into the Mil-Spec wire.

Table of Contents

- What are MIL-SPEC Wires?

- Common types of Mil-Spec Wires and Mil-Spec Cables

- Can you use Regular Hookup Wire/Lead wire and Mil-Spec Wire interchangeably?

- Conclusion

What are MIL-SPEC Wires?

Mil-spec wires, or military wires, follow the strict requirements of armies worldwide. They hold up under extreme conditions and rough use. These cables can easily withstand high heat and a lot of movement. Also, wear and tear, lubricants, solvents, and other chemicals do not affect it. There is an additional shield present to protect the wire from potential harm.

The Military uses cables for various purposes, including armor plating, electronics, airframes, antennae, commercial applications, and ground wires. Moreover, they also use it in the armament industry, particularly for interior wiring. Benefits include long service life, high resistance, and fault tolerance. The operating temperature of military-grade wire varies by kind but typically ranges from -80 to 260 degrees Celsius. There are two voltage options for the cables: 300 and 600 volts.

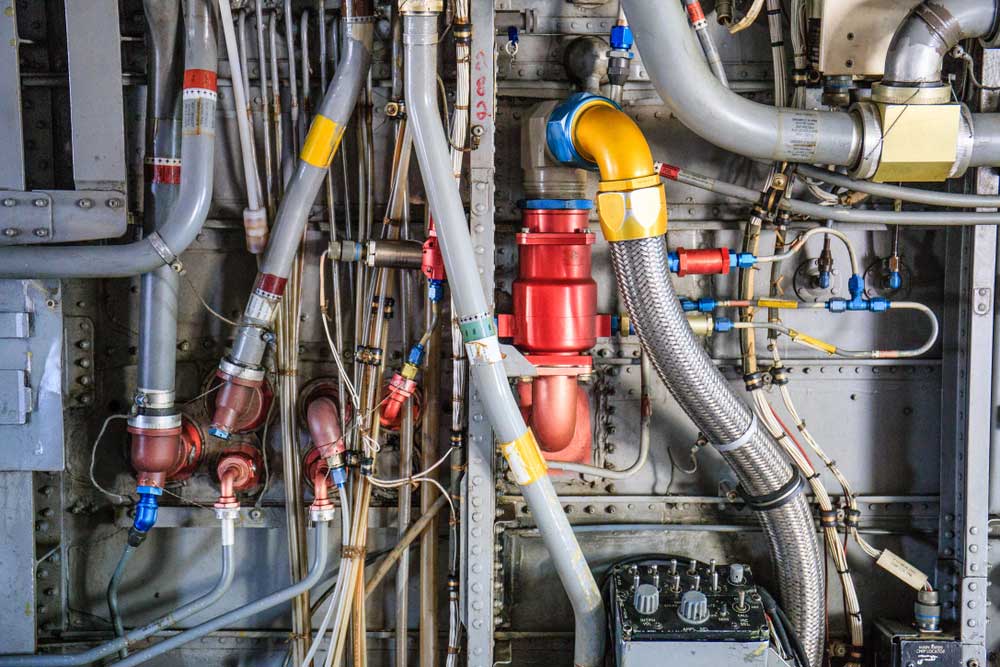

Caption: Color-coded mil-spec wires

Common types of Mil-Spec Wires and Mil-Spec Cables

Many Mil-Spec standards are available for wires and cables nowadays, but here are a few of the most common ones.

M22759 (SAE AS22759)

The Military developed the M22759 wire specification for use in unique aerospace environments. This type of wire is typically used for the electronics and engine controls of planes that have to work in wet and windy conditions.

M16878

PTFE, PVC, and ETFE are some insulating materials used to create M16878, or MIL-W-16878 compliant wire, which can tolerate extreme temperatures and voltages. The construction of these wires varies between products because they have to fit each. For instance, M16878/4 can be used for wire harnesses and power sources. As with M16878/5, it is designed for use in electronics that will face extreme temps.

M25038

The M25038 wire can withstand extreme conditions, including vibrations and direct fire. This wire is safe for use in complex circuits of aircraft.

M13486

M13486, like other Mil-Spec wires, comes in various types to meet the needs of a wide range of products. The M13486 standard covers low-tension cables in military tanks, trucks, and combat vehicles. These wires can withstand cold temperatures without cracking or breaking and remain flexible even when wet or bent.

M5086

The aviation, Military, and factory automation sectors use M5086, a multipurpose wire. The manufacturers use tin-plated copper core and PVC insulation, whereas its sheathing is nylon. In situations where you may expose the wire to wear and tear, impact, chemicals, or cutting, the M5086 cables are the best option.

Check the Military Wire Specifications Chart to find your needs.

Can you use Regular Hookup Wire/Lead wire and Mil-Spec Wire interchangeably?

People often wonder whether they can use regular wire to replace the mil-spec wire.

Defining the Terms of Military wires and Lead Wires

Single-conductor cables, or “hookup wire,” are usually present in various internal connections of different home gadgets. Thus you can find them in multipurpose motor cables, control cables, power cables, and circuit wires. The term “lead wire” can also refer to the wire used to make an electrical connection.

On the other hand, military wires are typically present in the internal wiring of appliances and, like hookup wires, only contain a single conductor. As a result, all mil-spec wires are hookup wires, except for their data transfer quality. However, the Mil-spec wire has greater flexibility, temperature and chemical resistance, and service life.

Explaining the Difference Between Military wires and Lead Wires

Is there any distinction between military and hookup wires if they serve the same purpose? The answer is the place of application.

- UL and CSA regulations in the United States cover simple hookup wire that isn’t designed for military use. UL 1015, 1007, 1061, and 1569 are some hookup wire specs. However, unlike the wire that the UL and CSA specify, the Military approves the mil-spec wires.

- For a similar alternative to UL/CSA approved hookup wire, you can choose the M16878. If you’re looking for something similar to a standard hookup wire but with some added qualities, you can consider the M16878 family (M16878 /1, M16878 /2, etc.).

- Popular mil-spec wires such as M22759 and M80104 differ in construction from hookup cables in the UL/CSA standard range.

Depending on the project’s budget specifics, it may make sense to use non-premium mil-spec wire instead of UL/CSA grade hookup wire. Therefore, you cannot use standard hookup wire in the Military. Thus, if you have a complex project, you can use mil-spec wire for whatever connection you need outside the Military.

Caption: complex wiring in aircraft system

Conclusion

Including simple Mil-Spec cable assemblies in your product is crucial, as it can have harmful results. When designing goods with strict requirements, like those used in the Military, it’s vital to use only components that meet those standards. Hence, it is crucial to have regular talks with your OEMs. It is essential to source high-quality wiring and cable assemblies.

Cloom has a record of serving as a supplier of military wire assemblies to OEMs. We produce Mil-Spec cable assemblies per customer specifications for various electronic systems. To avail of our services, contact us now.