Fiber optic cables are the unsung heroes of the digital world, transmitting massive amounts of data at lightning speeds. That social media app you can’t seem to quit, or that cable tv show you love so much is accessible to you thanks to fiber cable connectivity. In the world of fiber optic cables, pre-terminated fiber optic cable is like the coolest kid on the block.

Think of them as the high-tech equivalent of pre-packaged meals—ready to go right out of the box, no hassle required. Before going any further, let’s take a closer look at what pre-terminated fiber cables are.

Table of Contents

- What Are Pre-Terminated Fiber Optic Cables?

- How Is Fiber Cable Terminated?

- Advantages of Pre-terminated Fiber Optic Cables

- Tips for Choosing Pre-Terminated Fiber Cables for Your Requirements

- Pre-Terminated Fiber Cable vs. Field-Terminated Fiber Cable

- How do you remove pre-terminated fiber optic cable?

- Conclusion

What Are Pre-Terminated Fiber Optic Cables?

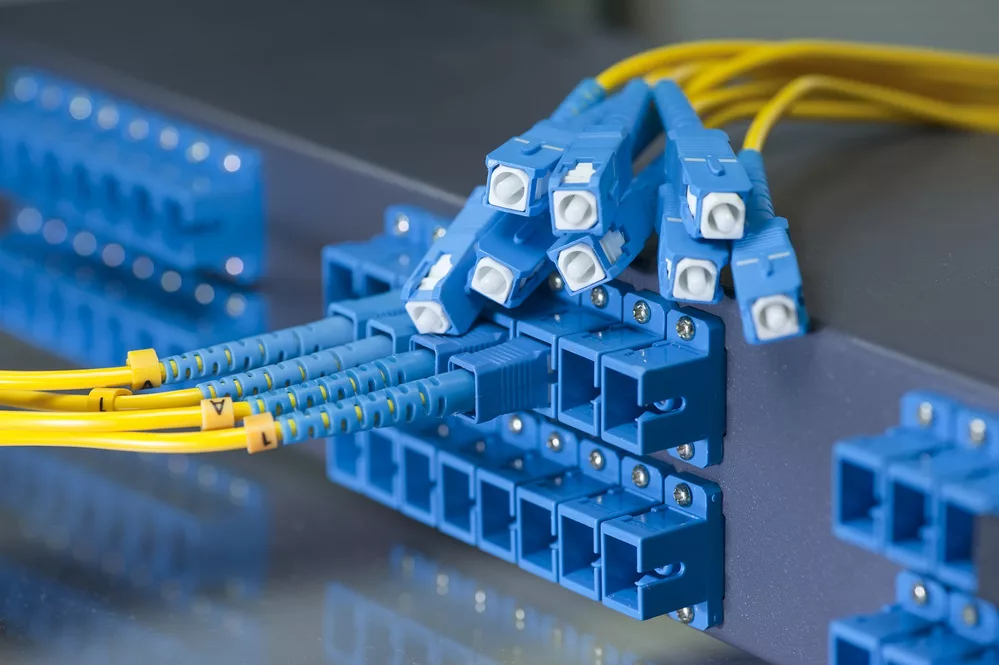

Fiber Optic cables are connected to ports on a hub.

Termination of fiber optic cable refers to adding fiber optic connectors to each fiber.

As the name suggests, pre-terminated fiber optic cables are cables the manufacturer has already terminated. They are a hassle-free solution when it comes to fiber connectivity.

Who loves breaking a sweat when you can plug in the cable, and voila? It’s up and running.

Unlike traditional fiber optic cables, which require extensive field termination, pre-terminated cables come with connectors already installed. This makes your cable deployment work much faster and cheaper.

How Is Fiber Cable Terminated?

Close-up image of a fiber cable connector

Termination of fiber cables is no walk in the park; that much we have established. It requires several variable tools and a great level of precision to get the best results.

There are two common ways to terminate fiber cables: connectors or splicing. But, they share a common goal, giving optimal performance (very low reflectance) while having high mechanical strength.

Each approach has its pros and cons, and the best choice for your network will depend on your specific needs and requirements. However, you can check out our meticulously crafted guide on the cost of splicing fiber optic cables to make the most out of your experience.

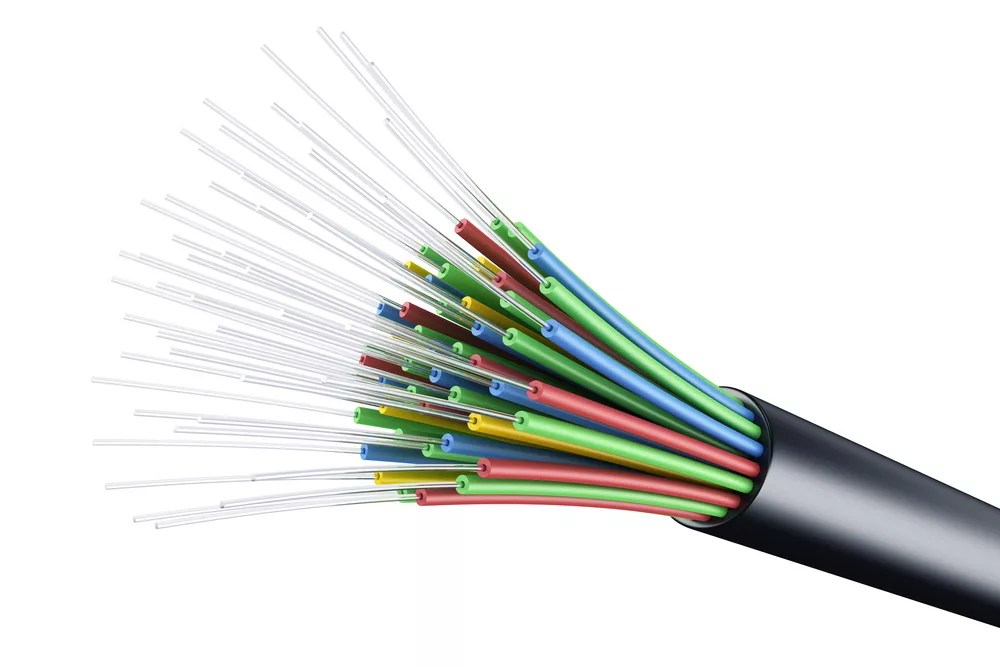

3D rendering of a fiber optic cable on a white background

Connector termination involves putting designed connectors at the end of the fiber strand. This method offers temporary connections, unlike splicing.

You must consider that the system must be compatible with the connector before purchase. If the installer doesn’t know the system before cable deployment, hybrid patch cords with multiple connectors should suffice.

Generally, always use pre-terminated armored fiber optic cable when deploying in harsh environments.

Splicing is suitable for making permanent connections. You have to join bare fiber strands directly using mechanical coupling or fusion for a perfect joint.

Fusion splicing is the preferred method for splicing fiber optic cables due to its low loss and low reflectance. Almost all single-mode fiber splices have fusion splicing.

Advantages of Pre-terminated Fiber Optic Cables

Fiber network cables patch

These cables have many advantages, given their ‘ready-to-use’ nature.

One must plug the cable into compatible fiber ports or devices, getting connectivity in the least time and cost. They do not require any preparation and testing.

They become a cost and time-effective solution by eliminating the need for a skilled laborer and resolving installation issues.

Pre-terminated fiber cables have also become popular because of their high performance compared to field-terminated cables.

Reducing carbon footprints because of low leftover waste materials associated with pre-terminated cables is a huge plus.

Tips for Choosing Pre-Terminated Fiber Cables for Your Requirements

Fiber cable on electronic board

Like any other purchase, various factors play a role in selecting premade fiber cables.

Connector Types

There are different types of cable connectors. Meaning you must be careful when choosing one suited for your applications.

However, the SC, LC, and ST connectors offer various locking mechanisms to secure your cable.

Cable Construction

It’s important to consider the type of cable construction when selecting your premade fiber cable. Some of the notable cable construction types include:

Interlock Armor Indoor Plenum

This cable type has the capabilities of an indoor plenum cable but with armor. The armor protects the cable from accidental damage in harsh environments.

Indoor Plenum

It’s a construction suitable for indoor applications. Most of these installations do not require an inner duct or conduit. Such cables produce less smoke than other types.

Interlock Armor Indoor/Outdoor Plenum

These cables have the combined perks of the indoor plenum and indoor/outdoor cables. The additional armor makes it a perfect candidate for burying it directly in the ground.

These hybrid cables are the way to go if you’re looking for versatility. With no indoor restrictions, they’re perfect for underground conduits. Remember that they may not be the best option for plenum spaces or aerial installations.

Outdoor Aerial with Messenger

Cables of this type of construction have a water-blocking gel that limits their indoor use to only 50 meters. However, they have steel messengers used to traverse across buildings and poles.

Outdoor

Underground conduit installations got much easier with this type of construction. They’re the go-to choice for outdoor applications and are filled with a gel that effectively blocks water.

So, these are worth considering if you’re looking for a cable that can handle the elements.

Fiber Type

Some of the most popular pre-terminated fiber type classifications include:

OM1 Cable (62.5/125 µm)

They are one of the most popular multimode fiber types and have been in demand since the 1980s. Their very low data capacity transmission property is, pushing them to obsolescence.

OM2 Cable (50/125 µm)

Capable of delivering speeds of up to 10 GB, they’re perfect for running 1GB Ethernet for distances up to 220 meters. And, with their bright orange jackets, you’ll never mistake them for any other cable.

OM3 Cable (50/125 µm Laser-optimized)

These cables are ideal when you want to upgrade to high speeds of 10 GB now or in the future. They are distinguishable using their aqua-colored jackets and can run 1GB ethernet up to 550 meters.

In long-range fiber optic network applications where distances exceed 300 meters, it is highly advisable to incorporate mode conditioning patch cords in the setup to mitigate signal impairments and ensure reliable transmission.

OM4 Cable (50/125 µm Laser-optimized)

OM4 cables are popular in modern-day data centers because they can run from 100 GB to 150 meters and beyond. They also have aqua-colored jackets.

Pre-Terminated Fiber Cable vs. Field-Terminated Fiber Cable

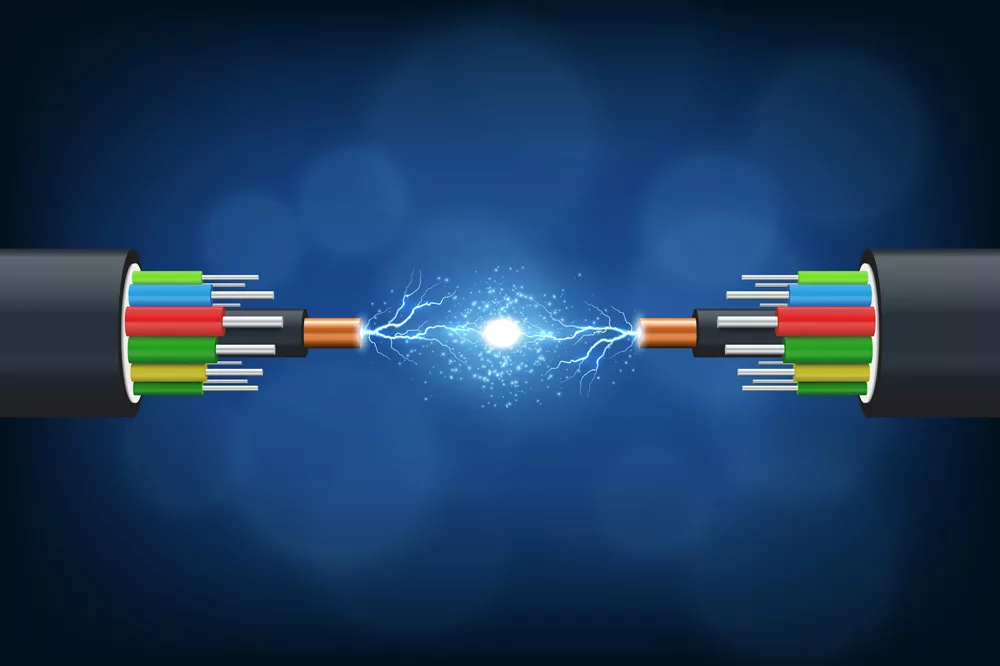

Two fiber cables with ends facing each other.

Field-terminated fiber cables require termination at installation sites, often by skilled personnel. Pre-terminated cables, on the other hand, ship with termination on order according to your needs, as mentioned earlier.

As much as premade fiber cables have their pros, they also have a countable number of cons. They are not easily customizable in length and are difficult to run through, especially if the connectors are bulky.

Field-Terminated Fiber Cables are known for their flexibility since cables are cut according to requirements. This also avoids wastage. You can easily pull bulky cables from both ends. The high labor costs in terms of expertise and quality equipment make the cable choice expensive.

The technician’s skills and experience determine the quality of cable termination, so achieving the best results isn’t always a sure thing.

How do you remove pre-terminated fiber optic cable?

Fiber cable cutter

Strengthen the yarn fibers inside the outer jacket by properly pulling the fiber optic cables. Using a three-hole cable stripper, remove a small part of the jacket to expose the inner core.

Loop the exposed yarn inside the cable, pulling the eye, and double-knot it for security.

Conclusion

Premade fiber optic cables come with attached connectors, eliminating the need for on-site termination and reducing installation time.

When you install a fiber optical cable, you will undoubtedly have to consider the termination type of the cables. Premade fiber cables provide a better option in terms of cost and time. They, however, have their downsides.

From the two termination classes, it would be objective to say that you should consider both types and choose the one that meets your requirements.