Electronics are an element of modern-day life. From kitchen to household cleaning, electrical equipment has aided every moment. However, it is impossible to build a piece of equipment without using a wire harness. You may have heard a lot about the cable harness and the elements it needs. But, what is the cable harness itself? Let’s dig in.

Table of Contents

Understanding Cable Harness

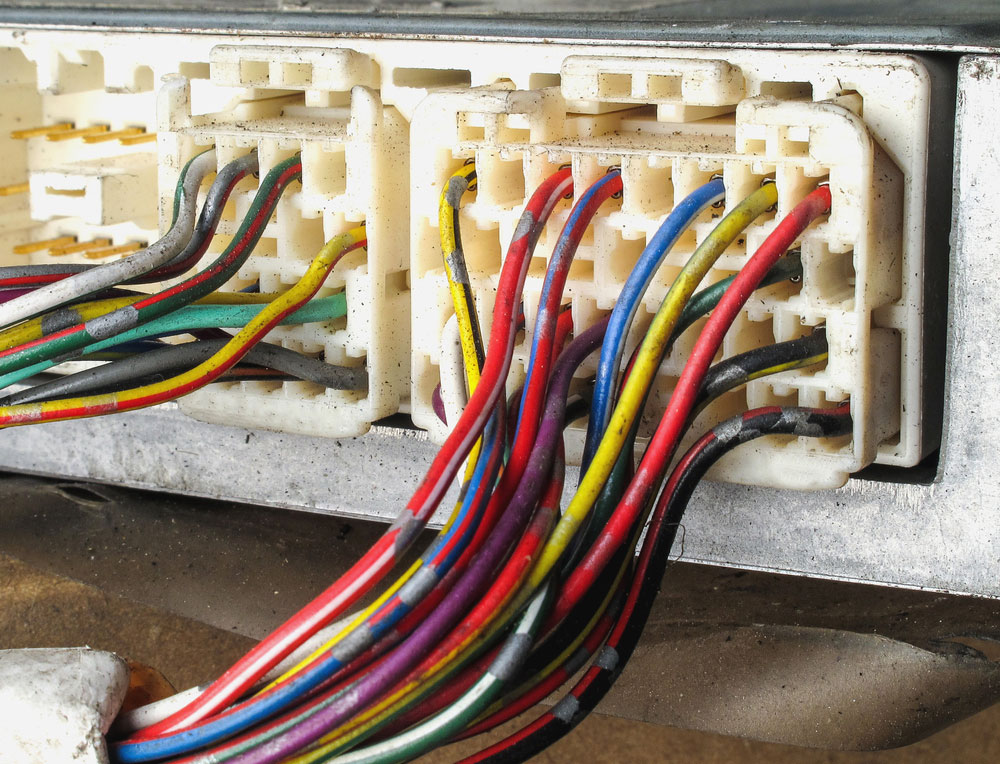

Caption: Wire harnessing in automobiles

Cable Harness, also called the wiring harness, wire harness, or wiring loom assembles multiple electrical wires or cables that transmit the electrical power or signals. You bound together many cables and wrap them with durable materials such as vinyl, rubber, or electrical tape conduit.

The wire harness is a part of many active industries. For instance, in large aircraft, spacecraft, heavy machines, and automobiles, you might see mile-long lines. Be it automobiles, machinery, or construction; cable harness has a much better performance over loose wires and single cables. The damage rate decreases significantly as you bind these together and transform them into a cable harness.

Therefore, in a cable harness, wires are much more protected against moisture, cuts, abrasions, and adverse effects of vibrations. Moreover, by converting the wires into a non-flexing bundle, you can also decrease space usage and the chance of short-circuiting.

In the case of installing the wire harness, now the technician has to fix only one bundle of wires. Thus the installation time decreases, and you have more efficient ways to repair the damage if any. Also, you can lower the chances of electrical fires by using a flame-retardant sleeve for binding the wire harness.

Production of Cable Harness

Caption: Colorful wire harness in the machinery

For designing the cable harness, you have to consider the electric and geometric requirements of the intended place of installation. Next, you will create a diagram either on paper or on a software tool and conform it to the standards of the inspection team. In the end, you will find the correct elements and start assembling them.

How to make a wire harness?

The process of making a wire harness is not tricky if you are equipped with the right tools and skills. Hence, you will follow these steps to complete the production:

- Cut the wires into the desired length using a special wire cutting machine. You can also print these wires during the cutting process or separately

- Then, you will strip the ends of the wires to expose the metal part and fix it with suitable connectors or terminals

- Next, you will fix these cables onto a pinboard or assembly board according to the design

- Now, cover it with any protective sleeves, insulation, or conduit, and it is ready to fit in any vehicle, machinery, or equipment.

Why is the Harnessing Process not Automatic?

Despite every automated process, hand manufacturing is still the primary method to create a cable harness. It is because there are many small steps involved which need proper care and attention, such as

- Routing the wires through protective sleeves,

- Taping the branch outs of wires with fabric tapes,

- Inserting one sleeve into the other,

- Fastening the outer strands with clamps, tapes, or cable ties,

- And crimping the terminals onto wires.

These steps are challenging to automate. Yet you cannot complete a successful wire harness without them.

However, you can automate the steps like cutting the wires, stripping them, crimping their terminals, fixing plugs, soldering the ends, and twisting the wires. It will cut off most of the time in preproduction, and you will have the wire harness ready in lesser time.

How to Test the Wire Harness?

Once a cable harness is complete, you will conduct various tests to ensure the quality and effectiveness of functioning. For that, you can use a test board to measure the harness’s electrical capabilities.

Thus, you will input the electric signals of values that the other circuit boards are already being tested through and check how the harness will behave. Then you measure its ability to function in the simulated circuit.

Another popular method is the “pull test.” You will connect the harness to a machine that will pull it constantly. You will get the measures of how good the cable harness’s strength is and whether the conductivity of the cable changes or not. It will ensure that the cable harnesses are effective and safe.

Industry Quality Standards

Caption: Splice Electric Wiring

Customer specification for the wiring harness takes the highest priority. But what If the client describes no such requirements? In North America, to deal with such situations, you can use the cable harness specifications standardized by IPC.

The publication under IPC standards is revised frequently to remain up to modern standards. Moreover, it includes electrostatic discharge production, installation, conduit, crimping, pull test requirements, and other critical steps to the production process.

These standards by the IPC are based on the product classifications under three defined product categories. These are;

- Class 1: General Electronic Products, where the end product’s functionality is essential. It includes toys and items that do not have critical use.

- Class 2: Dedicated Service Electronic Products, where you need consistent yet extended performance, but it may not be uninterrupted. In case of failure of such products, you will not face any severe dangers.

- Class 3: High-Performance Electronic Products, for the products that should be consistently up for work. Hence, the environment where these harnesses are operating is uncommonly harsh. It includes ventilators in hospitals and the military. Here, the period of failure is intolerable, and many lives might be at stake.

Conclusion

To conclude, the cable harness is a bunch of wires tied together and fixed in different types of machinery. Their uses can be critical or straightforward. Hence you need to follow the specific design and the standards in the production process.

Here at Bloom, we offer custom wiring assembly and multiple types of connectors, so you’re your connection is made with attention to detail. To avail of our services, contact us now.