You can find wiring systems anywhere, from a home electrical project to the advanced aerospace industry. You’ll hear a wide range of different terms regarding these setups. And the most common phrases include cable assemblies, wire harnesses, and a wiring loom.

These all have similarities. But there are different from each other in some way. And here is what you should know about a wiring loom and its differences from other cable ties! Apart from moving data, these setups also keep wire bundles in order.

Table of Contents

What Is a Wiring Harness?

Caption: A bunch of wiring harnesses on an automobile

First, we’ll cover the basics and describe the difference between a cable and a wire. Whether it’s an industrial wire or another type, it’s a single conductor. The conductor wires usually use aluminum or copper, which can have many strands.

On the other hand, a cable contains many wires. You can identify them with different sheath colors. Furthermore, a cover protects from abrasion and external factors.

A wiring harness includes joining several wires together to save space. This system first appeared in the automotive industry over a century ago. The goal is always to prevent a single wire from getting loose. Joining multiple wires together also reduces the odds of vibration damaging a single conductor. Cars and other machinery often vibrate while in operation. This protection is vital, especially since it keeps things neat as a bonus.

If it’s simple, an electrical wiring harness won’t have terminations. But complex automotive wiring can feature terminating units. You’ll see the electrical tape, cable ties, and heat shrink as methods to connect the conductor wires.

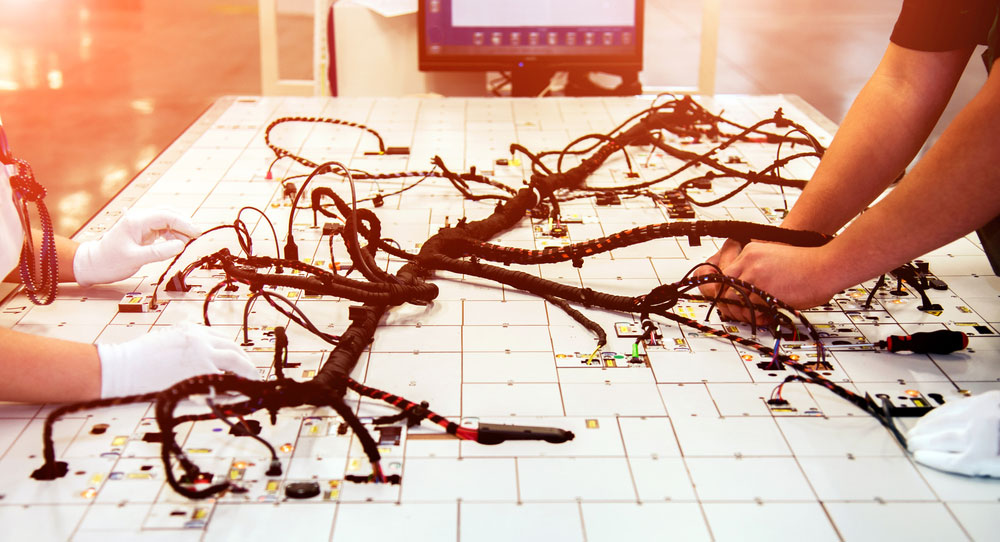

Caption: Employees checking the quality of a wire harness

Now, the wiring harness manufacturer’s rules are simple. The primary goal is to keep wire harness assemblies neat. The process starts with a layout to follow when assembling the harness. Wires should have the necessary length. Next, they connect delicate wire bundles. It saves room while reducing damage risk. Also, you know where the black wire and each other conductors are.

Check out the pros of these setups:

- They are simple to make. Whether it’s simple setups or complex aircraft wiring harnesses, the production is simple.

- You won’t pay much per unit. The cost is reasonable, and you can save by outsourcing the project to a custom wiring harness service.

- Fast delivery. The simplicity is what ensures a quick turnaround.

- Reduce the risks of electrical problems. If you keep wires in order, it minimizes the risk of anything going wrong.

- Keep everything neat. It leaves a better impression when you check the wiring. Furthermore, it helps you discover the faulty wire if it happens.

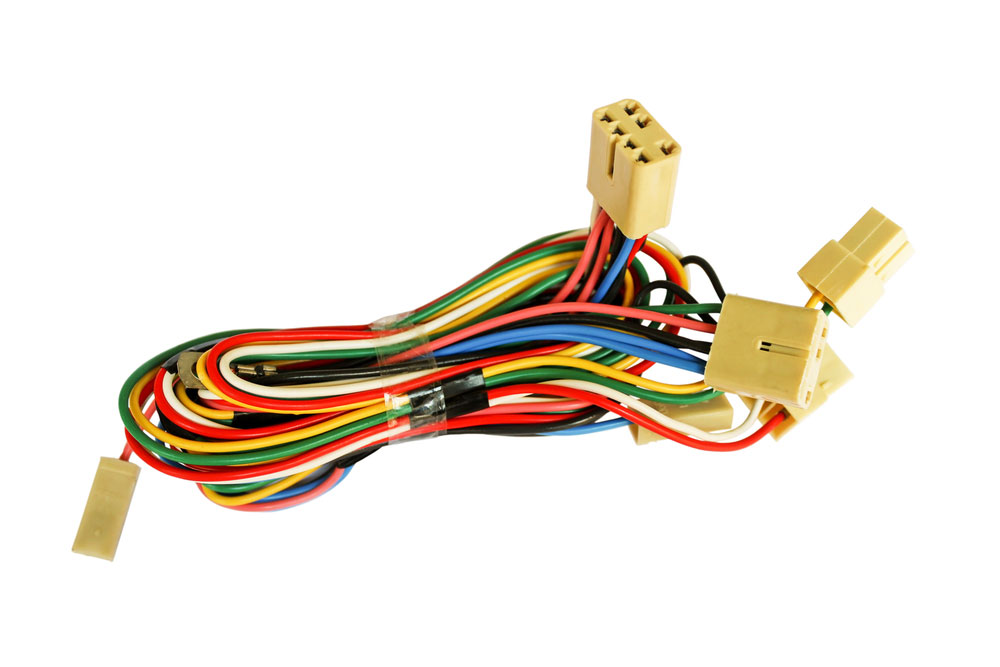

What Is a Cable Assembly?

Caption: A large cable assembly with multiple colored wires

A quick review – wire is a single conductor, and a cable contains two or more wires. Now, a cable assembly can include both. It’s a setup that can hold cables and conductor wires together. It would help if you also had a layout ready before making this assembly.

On the other hand, protection for cable assemblies can be from different materials. Those include fire, heat, water, and physical damage. Most use special plastic, rubber, or vinyl. They form a sheath to keep the cable assembly safe from external elements. It results in better protection, making them a high-quality option for an electrical project.

What Is a Wiring Loom?

Caption: An example of a wiring loom

The wiring loom is a step forward compared to cable assemblies and harnesses. These complete wiring packages connect many harnesses and packs into a single system.

At first glance, the loom seems like a bulky item. It has many wires, terminations, and other components. The crucial advantage is that it maximizes value for money. You don’t connect each assembly into the electrical product separately. Instead, you use a single system.

For standard products, this means you save material per every unit made. It allows getting the wiring at a lower price, saving total costs. Furthermore, you are being eco-friendly by minimizing material waste. Ease of installation is another benefit of affordable wire looms. Most creators provide complete installation manuals to ensure everything goes smoothly.

Another thing you should know – wiring loom connection faults are rare. Stick to reliable shipping providers that perform the necessary safety check. That ensures a minimal risk of issues. That’s important because you won’t have to pay a fortune on costly repairs. It’s why wire looms are suitable for construction machinery and other complex projects.

Conclusion

A wiring loom is a system that helps to keep complex cable and wire assemblies neat. It has many uses, which implies you can customize it to your needs. At Bloom, we have advanced skills and experience working with wiring solutions. Don’t hesitate to contact us and place a customized order for the desired wiring loom!