Aluminum vs. Copper electrical wire has long been a fierce competitor in electronics wiring.

Both metals efficiently transmit electric energy through the valence electrons available in their structures.

However, despite their wide range of similar applications, Aluminum and Copper differ worlds apart.

They all have specific pros, cons, and differences that affect their suitability and performance, as covered in this cheat sheet.

Table of Contents

- Aluminum Wire Pros and Cons

- Copper Wire Pros and Cons

- Aluminum vs. Copper electrical wire: The Ultimate Comparison

- Aluminum vs. Copper Electrical Wire – FAQs

- Aluminum Vs. Copper Wires at a Glimpse

Aluminum Wire Pros and Cons

Pros

- Can resist corrosion, though not better than Copper

- More affordable

- Lightweight

- More malleable

Cons

- Lower heat and electrical conductivity than Copper

- Susceptible to galvanic corrosion

- No longer used

Coaxial aluminum wire cable

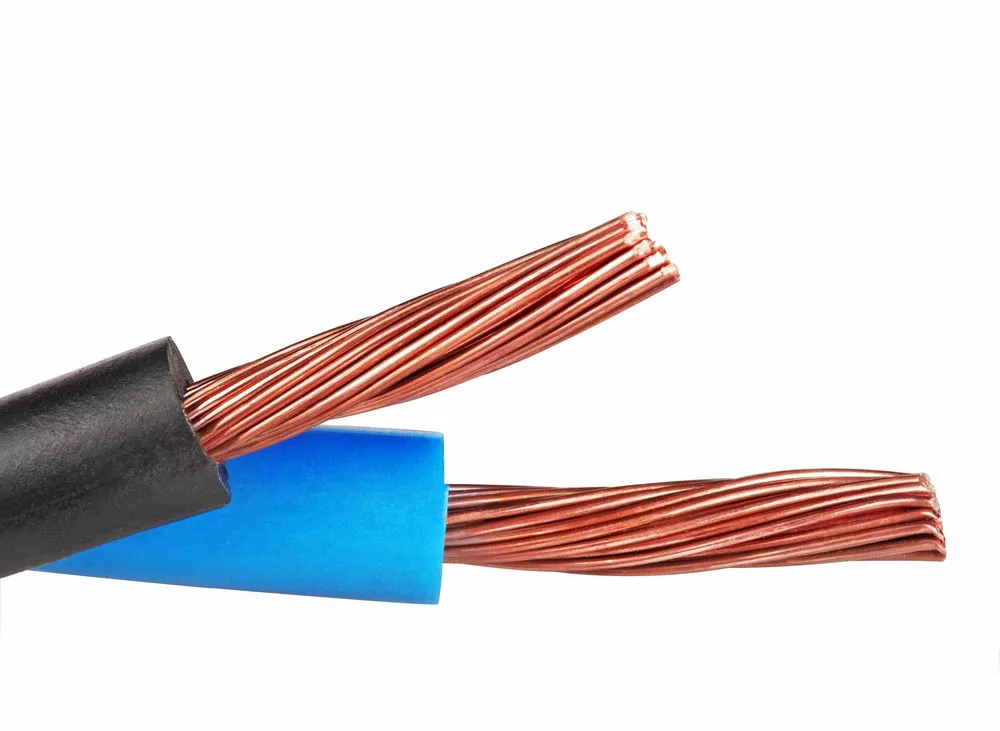

Copper Wire Pros and Cons

Pros

- Corrosion resistant

- More durable

- Excellent electric conductivity

- Excellent heat resistance

Cons

- More expensive than aluminum

- Rigid and more difficult to handle during installation

Copper electric wire

Aluminum vs. Copper electrical wire: The Ultimate Comparison

Beyond the pros and cons, there are numerous factors to consider when deciding between Copper and Aluminum wires. After carefully evaluating the two options, we came up with a detailed guide to help with easier choices:

Copper vs. Aluminum Wire: Current Capacity

The current capacity is the primary (and the first) difference to look for when comparing Aluminum vs. Copper wires. By definition, this is the maximum amperes of current the wire can comfortably and continuously carry without outpacing its temperature rating.

Aluminum has approximately 40% lower current capacity than Copper of the same size. Copper has a more compact structure compared to irregularly structured aluminum. This makes the flow of current much smoother and with less resistance than aluminum.

To compensate for their low current capacity, an Aluminum wire of the same current capacity as Copper is often larger. This explains why many engineers prefer Copper over aluminum for high-current and high-temperature applications.

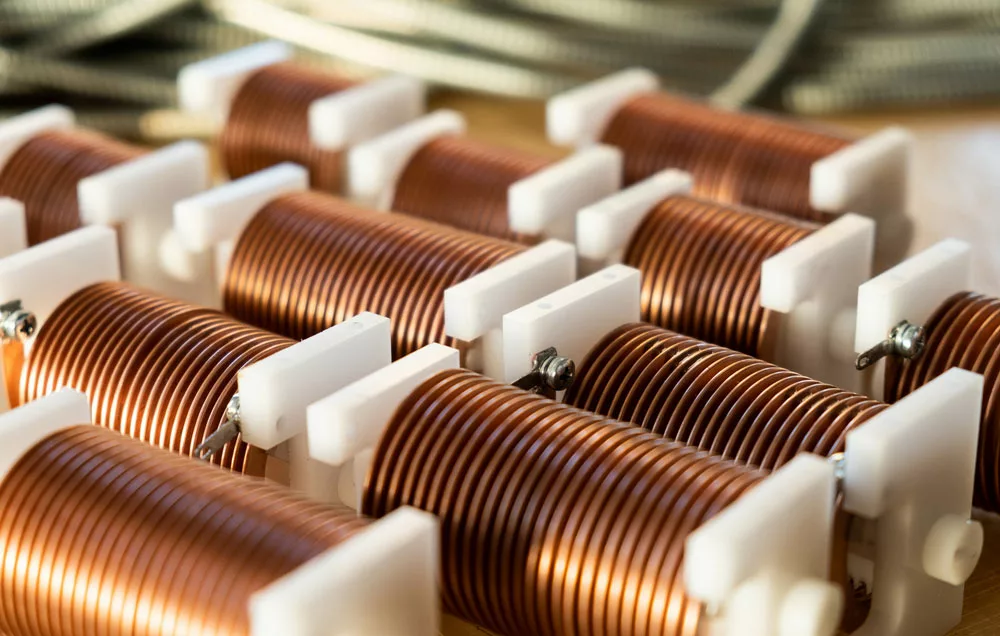

Close-up of high-frequency power with copper wire

Aluminum vs. Copper Wire: Price

Aluminum dominated homes and commercial wiring in the 60s and 70s as an affordable alternative to the copper wire with a spike in price. To date, it is still about half the price of copper wire.

The main reason behind the spike in copper wire is the production cost. To begin with, it is scarce, and the companies would spend a lot more on acquiring the material than aluminum.

Besides, Copper is more rigid (less malleable) than aluminum. It takes more time, effort, and resources to wind a copper metal into a wire of desired length, diameter, and current capacity.

Copper vs. Aluminum Wire for Underground

Copper wire is ideal for underground wiring. They can safely live underground for 100 years compared to aluminum, which cannot last more than 80 years.

Ideally, Copper wire forms a protective film of a reddish-brown cuprous oxide that increases its ability to prevent corrosion. This thin plating often remains intact and can be readily repaired regardless of soil condition.

A Copper wire also doesn’t react and cannot be affected by steam or water. On the other hand, Aluminum wire readily reacts with water to form Aluminum hydroxide and hydrogen deposits at room temperature. Therefore, using an Aluminum wire underground increases the risk of dissolution, especially in areas under frequent earthquakes and tsunamis.

The technician repairs a copper wire.

Aluminum Electrical Wire vs. Copper Strength

Copper has more tensile strength and flexibility compared to Aluminum wire. For perspective, Copper’s Brinell hardness is between 40-50, while Aluminum’s Brinell hardness is approximately 70. Metals with higher Brinell hardness are softer and more likely to suffer more nicks than those with a lower Brinell rating.

On the Mohs scale, Aluminum rates 2.75 in tensile strength, after Sodium 0.5, Lead 1.5, and Tin 1.5. The copper rate is 3.0 after aluminum. These show that Copper is more resistant to deforming, breaking, or chipping under tension than aluminum. Copper also resists stretching or being drawn back more efficiently than aluminum.

Choose Copper wires over Aluminum wires for bending and twisting applications since they won’t easily break apart.

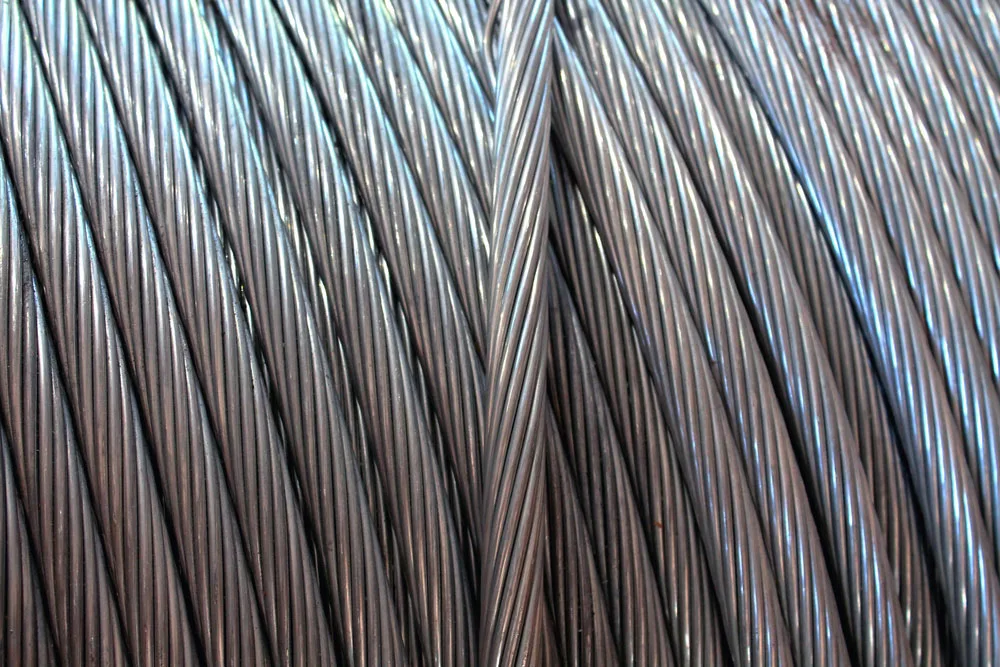

The Aluminum electric wire coil

Aluminum Electrical Wire vs. Copper: Home Wiring

Aluminum and Copper’s wires are both popular choices for home wiring. However, Copper is the best alternative since it conducts electricity more efficiently.

Copper also has higher heat conductivity than aluminum. They maintain conductivity without needing special connectors as they expand uniformly and keep their connections intact.

Additionally, they don’t overheat, hence guaranteeing more safety. Even without regular maintenance, Copper wires maintain their efficiency and remain reliable for years of use in residential houses wiring.

Aluminum wires are generally susceptible to overheating. As a result, there are higher risks of fire hazards, especially during the electric surge.

They even become more dangerous when not properly installed and poorly maintained. To minimize this risk, technicians install Aluminum wires with specialized connectors that cushion the cables as they expand and contract to prevent loose connectivity.

Aluminum vs. Copper Electrical Wire – FAQs

Which Wire is Better: Copper or Aluminum?

Copper wires are better than Aluminum wires for many reasons. They are durable, stable, and perform better due to their higher electric and thermal conductivity.

You’d only want to use an Aluminum wire over the Copper wire if you are tight on budget. However, if you consider safety and other perks that come with Copper wires, they’re worth every coin.

Why is Aluminum Wiring no Longer Used?

The primary reason is their risk of fire hazards. Aluminum wires expand and contract rapidly due to low thermal and electric conductivity.

As they expand, the wires loosen connections at the switches, outlets, and lights, increasing the risk of fires. Also, aluminum oxidizes when exposed to heat, potentially resulting in an electrical fire.

What is the Benefit of Aluminum Wire Over Copper?

Aluminum wires have only two benefits over Copper wire: they’re less expensive and more malleable. You can get the same Aluminum wire size at half the price of Copper wire. More malleable means are easier to bend or hammer in any shape during installation.

Is Aluminum Wire Good for Electricity?

Aluminum is good for electricity, especially when properly installed and maintained. However, it is not as good as copper wires and is not widely used currently. You can find stranded aluminum cables in feeder lines and distribution wiring.

Aluminum Vs. Copper Wires at a Glimpse

The difference between aluminum and copper wire is very clear. Copper is the best option and the most commonly used in home and industrial wiring. Aluminum is no longer common. However, it is a great alternative to copper if you are on a budget.