For modern-day equipment, batteries are essential.

Whether it is a heavy vehicle, boat, fleet truck, or fuel-powered automobile, you need a battery to start either of them.

Yet, to function correctly, they must link the battery to the rest of the system without fail.

For that, you will need a medium for connection for power transmission. Yes, that’s what we will talk about, battery cables.

Table of Contents

- What are Battery Cables?

- How do Battery Cables Work?

- Facts about Battery Cables

- How to Assemble a Battery Cable?

- Four Things to Double-Check While Choosing Battery Cables

- Battery Cable Replacement

- Battery Cable Repair Splices and Their Application

- Custom Battery Cable Assemblies

- Conclusion

What are Battery Cables?

Caption: Start Battery of a Car

Battery cables and the lugs required to connect them to a battery are heavy AWG (American Wire Gauge) copper wires on industrial machinery. There are two types of battery cables.

- The positive Battery Cable is red and attaches the battery to the car’s computer.

- The negative Battery Cable is black and connects the battery to the vehicle’s chassis to ground it.

As they work together, they allow the power to flow inside a closed loop until you turn the vehicle off.

Battery cables are rigid since they are manufactured with heavier copper wire strands. Also, manufacturers use PVC insulation and cross-linked polyethylene insulation (XLPE).

However, battery cables hold them once you bend them into shape, even if they are challenging to turn.

Moreover, their insulation can survive high temperatures beneath the hood, resist gas, oils, and lubricants, and resist battery failure.

Automotive battery cables usually are rated at 60 volts in terms of voltage.

How do Battery Cables Work?

The working of Battery cables is simple. The battery’s positive wire will go to the starter solenoid and power it.

In contrast, the negative line leads to the chassis of the vehicle to ground it.

That way, they allow all the parts to create their circuits once their specific switches become active.

Caption: Starting Engine with a battery

Facts about Battery Cables

Copper cable is an excellent electrical transporter. But, copper conductor corrodes since electrolyte (or acid) in all vehicle batteries is highly corrosive.

A battery needs this substance to work. Unfortunately, this same substance promotes rusting. Since the seal between the battery housing and the post allows some acid to escape.

These fumes increase battery wire abrasion with moisture, heat, dirt, and other chemicals.

Corrosion takes numerous forms, some visible, and some not.

Thus, cleaning the battery post of corruption and ensuring adequate contact between the battery cable terminal and battery post are essential steps in successful protection against corrosion.

How to Assemble a Battery Cable?

The mechanics may find it better to repair the old, worn-out battery cables in some cases instead of completely replacing a battery.

It is possible to purchase the pre-made cable and lugs separately. Now, we will see how to assemble a battery cable.

For that, you will need:

– Black Battery Cable for Negative

– Red cable for Positive

– Heat shrink Tubing

– Heat Gun

– Battery Lugs

– Insulation Stripper

– Paint Marker

– Measuring Tape

– Hand Crimper

Steps

- Measure the red cable as one foot and mark the ends with the marker, which you will insert in the lug.

- Now, strip the insulation and attach the lugs to the cable. Make sure to push the lug all the way.

- Then, put it inside the jaws of the Hand crimper and crimp it twice.

- Next, slide the heat shrinking tube over the crimped area and heat it with the heat gun. It will secure the ends like battery terminal covers and ensure no strands are poking out of the lug.

And there you have it, a cable ready to be attached with a battery.

Four Things to Double-Check While Choosing Battery Cables

When constructing battery cable assemblies, these things need a double check to make a reliable connection.

Caption: Battery wires with jumpers

Wire Gauge

Battery cable is offered in various wire gauges to meet the needs of different power applications.

The greater the diameter of the line, the more voltage it can carry.

Thus, according to the use, location, and heat flux the cable will face, the type of Gauge Battery Cables will vary significantly.

Moreover, you can use the SAE standard for an automotive battery setup.

Whereas for residential and commercial uses, you will get help from the National Electric Code (NEC) standard and local regulations.

Stranding

Another factor for determining the type of cable is the number of strands. The greater the number of strands, the more flexible is the cable.

However, some automobiles might not require loose wires as there are.

Thus, you can use a lower strand count cable in such places.

However, suppose mobility is essential, or the cable needs bending.

In that case, you must opt for flexible lines with a higher strand count. Moreover, the wires with more strands also offer better conductivity due to increased surface area.

Insulation

Then comes the insulation type of the cable. Since the battery cables will face higher temperatures and constant exposure to dust, oil, and chemicals, the insulation should handle all these things.

Common insulation materials for the battery cables are PVC, EPDM, and XLPE. Since a conductor with polyvinyl insulation is affordable, suitable for higher temperatures, and resilient to environmental factors like ozone, UV radiation, etc.

Connectors

It is possible to connect batteries using a variety of connector types. The regular battery terminal, which fits over a lead post, and the ring-lug terminal are the most common.

Most connectors are made of copper and are available in two finishes: plated copper and bare copper.

Moreover, straight and right-angle layouts are also available, as they are designed to accommodate different wire gauges.

Battery Cable Replacement

Follow these steps to replace a battery cable.

– Inspect the battery components and see what needs replacement. Also, locate the Negative and Positive of the battery.

– Remove the negative terminal and disconnect the grounding system. It is standard practice so that you can avoid any accidental shocks.

– Then, remove the positive terminal cable.

– After that, open all the securing mechanisms at the top of the base of the battery. Then, lift the battery from the Engine.

– Disconnect all the cables from the vehicle and discard them if they are not working.

– Take new cables and compare them to the older ones in terms of length and connector type to take the correct battery cables.

– Now, install the new cables in the vehicle, in the same manner, you removed them in the above steps.

– Secure the cables and reinstall the battery. Now, connect the wires to the battery as well.

– Test whether the installation is successful by starting the vehicle. If any issues occur, revisit the steps above.

Battery Cable Repair Splices and Their Application

You can use the repair splices to replace damaged cable parts quickly. Also, battery harness assemblies are standard in vehicles.

Replacing the entire harnesses if broken or rusted is costly and complicated. So, do not replace the whole cable, Rather replace the broken or corroded piece.

Moreover, replacing a damaged terminal is as simple as unplugging the battery and re-plugging it.

Repairing the terminal end of a battery cable is more accessible and more practical with splices.

To connect the battery cable repair splice, you can turn the vehicle off and disconnect the battery.

Then, cut the wire near the terminal and strip the insulation from the end.

Next, enter a proper cable splice and crimp using a crimping tool.

Reconnect the battery cables and tighten the terminals on the battery posts.

Custom Battery Cable Assemblies

Here are a few cable harnessing types from which you can choose.

- Tapered-Post Battery Cable

- Flat/Ground strap

- Fused Battery Cables

- Booster Cables

- Ring-to-Ring Battery Cables

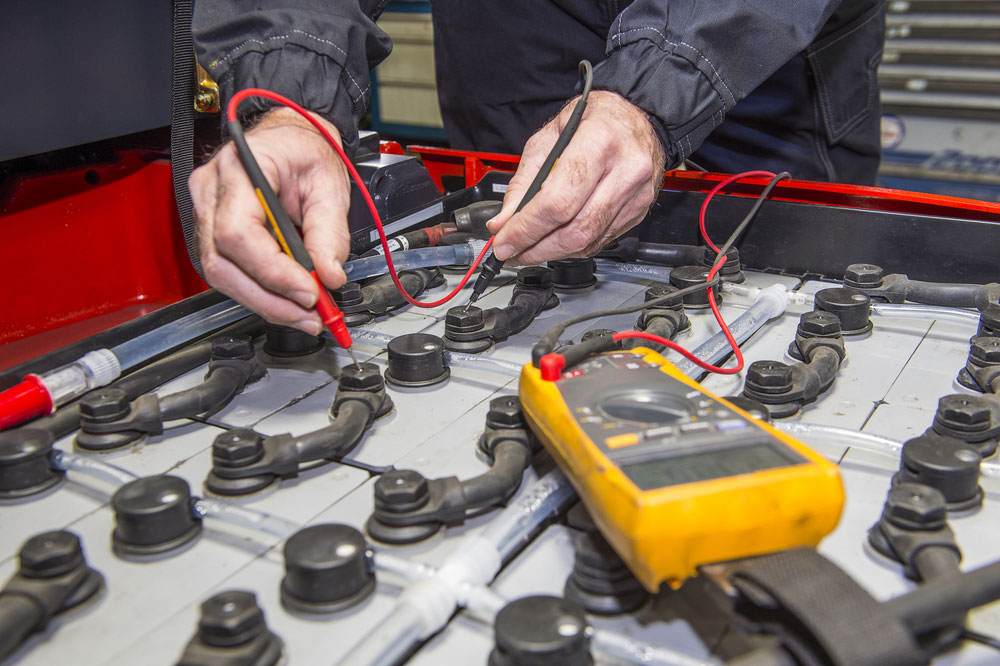

Caption: Battery testing of heavy automotive

Conclusion

Harnessing a proper Battery cable assembly is vital since all the connections will depend upon it.

Moreover, it will protect the wires from abrasions, moisture, and vibrations, lessening the risk of shocks.

Here at Bloom, we offer cable assemblies and wiring harnesses. To avail of our services, contact us now.