Custom M12 Overmolded Cable-For rugged data connections, automotive, aerospace, agriculture, marine, warehouse automation, and robotics use ethernet cables. The cables include m12 ethernet connectors. Many industries are replacing standard RJ45 connections. Because the m12 connectors are small and circular, creating a solid seal with its mating receptacle. They can withstand harsh environmental conditions and high strain, thus offering continuity. Today, we will have a clear picture of the custom m12 over-molded cable.

Table of Contents

- What are M12 Circular Connectors?

- Applications of M12 over-molded cables

- Why choose a custom M12 overmolded cable?

- Things to consider when picking Custom m12 overmolded cable

- How to assemble a shielded M12 crimp field-wired connector?

- Conclusion

What are M12 Circular Connectors?

The M12 circular connectors are keyed connectors having a 12mm locking thread. You get a rugged yet flexible connection for your equipment with these connectors. Initially, industries used them for corrosive environments. However, you can now use them in factory environments that require high-speed data transfer.

M12 connectors are non-removable and attach securely through soldering. They comprise stainless steel or brass plates and thus can easily withstand heavy-duty applications, including rust and corrosion. These connectors can work at high-temperature extremes ranging from -40 degrees Celsius to 85 degrees Celsius.

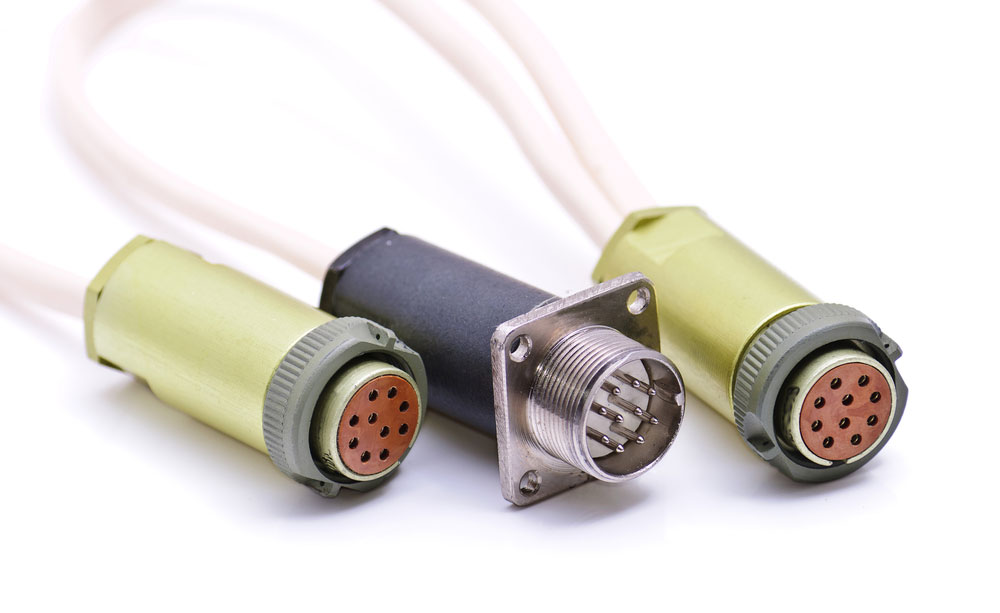

Image: connectors

Standards: The M12 connectors belong to the IEC 61076-2-101:2012 standard. It started in 2003, and presently it is in its third version, push-pull M12 or IEC 61076-2-010:2021.

Coding: An M12 connector is compatible with other M12 connectors with the same coding. They are given definite codes that define their pin counts and their arrangements to avoid confusion. The different m12 connectors based on coding are:

- A (3-17 poles)

- B (2, 4, or 5 poles)

- C (3 to 6 poles)

- D (4 poles)

- K (5 poles [4+PE])

- T (designed for DC power connections)

- X (8 poles, up to 10 Gb/s),

- Y (power and data in a single cable; 8 poles in a group of 4)

Cable considerations: Cat5e and Cat6a cable use M12 connectors.

Image: Cables with cable connectors

Current rating: M12 can withstand voltage up to 16V.

Mounting options: These include through-hole, wave soldering, and surface mount.

Materials: you can find M12 shells in brass, stainless steel, copper, gold, and other alloys.

Ruggedization: M12 cable assemblies can withstand harsh environments such as high temperatures, chemicals, radiation, etc.

Sealing: You can find these connectors in different versions, including IP67, IP68, and IP69. These protect fluid and particle ingress.

Interference: Shielded and unshielded cable assemblies protect devices from electromagnetic and radio-frequency interference.

Handling advantages:

For blind mating situations, you can use a bayonet, screw type, and connectors with the push-pull mechanism. You can connect these connectors quickly and easily. Further, to ensure mating, you can take the help of color codes, LED options, and keying.

Suppliers: Many manufacturers design a wide range of M12 connectors, such as:

- Amphenol Industrial

- Amphenol LTW

- binder

- Bulgin

- ERNI

- HARTING

- ITT Cannon

- JAE, LEMO Connectors

- Lumberg, METZ Connect

- Molex

- Norcomp

- Phoenix Contact

- TE Connectivity

- WAGO, Weidmüller

Related products: A wide variety of alternate options are available, such as:

- M8 Circular connector

- Ethernet Rj45

Image: coaxial cable connectors

Applications of M12 over-molded cables

Several industries use M12 connectors for varying purposes, such as

- Production of Automatic equipment

- Power Equipment

- Outdoor LED installation

- Mining machinery

- Hydraulic machine

- Temperature transducer

- Pressure transmitter

- Electromagnetic valve

- Meters and instruments

Why choose a custom M12 overmolded cable?

You can create an overmolded cable with assembled backshells and field connectors. However, industries use mold dies to create over-mold M12 connectors because:

- Firstly, it helps the connector makers to create small and large production runs of cable assemblies for customers’ critical requirements. These include pinouts, connector orientation, design specifications, and key configurations.

- Secondly, you can seal the cables assemblies and connectors strong enough to withstand rugged environments. It also provides resistance against shock, abrasion, and impact.

- Thirdly, mold dies to create flexibility at the exit point of the cable. As a result, it protects the cable from general wear and tears.

- Fourth, metal backshells are not needed as molded assemblies have better quality, a good appearance, and a pleasant feel.

- Also, the mating of each pair becomes easy, and thus installation becomes simple.

- Finally, it reduces human errors drastically.

First, the makers put the unmolded cable assemblies in the molds or precisely created tools having a safe exit for cables. Then, they close the molds and fill the cavity with low-pressure molding material. As the plastic cools down and solidifies, the process results in a single and seamless piece.

When the makers seal the connectors and cable assemblies together, it creates a ruggedized package. Industries use the 2-Shot approach to overmold the inline PCBs and smart connectors when there is a need for more wear resistance and sterilization.

Things to consider when picking Custom m12 overmolded cable

To deploy the best possible solution, you need to know the key variables required.

Angle

The angle of a connector is an important consideration, especially when tight spaces. If you put the straight connectors in a cramped area, they will wear over time. Also, using the correct angle will make your workspace look clean and organized.

Jacket Type

There are three types of jackets in overmolded cables. The use of cables depends on their jackets also.

- Polyvinyl chloride: PVC is a standard cable jacket and comes at a lower price. This jacket provides water resistance and protection against chemicals. However, this jacket is prone to hardening or cracking when exposed to oils. You can use these for moderately abrasive uses.

- Polyurethane (PUR): This is more durable and flexible than PVC. You can use them for abrasive production areas and applications with chemicals and oils. However, it can stick to itself due to its tackier surface, resulting in tangling.

- Thermoplastic elastomer: These cables can operate at a wide temperature range (from -25 degrees Celsius to 125 degrees Celsius). Further, it also protects against UV, heavy oil, and salt water.

IP rating

Industries use different IP ratings in their settings.

- IP65 protects against low-pressure water sprays.

- IP67 protects cables when immersed in water up to 1meter for 30 minutes.

- IP68 protects cables when immersed in water for a long duration and with high pressure.

- IP69K protects from high-temperature and high-pressure water jets.

Code

To make your device and cable work together, you must use the proper connector coding.

- A-code for sensors and actuators

- B-Code for process field bus connections

- C-code for AC power

- D-Code for 100 MB ethernet cables

- X-Code for 10Gb Ethernet cables

Pins/Position

The pins or position of the cable must match the ports. There can be a minimum of 3 to a maximum of 17 pins in the cables.

How to assemble a shielded M12 crimp field-wired connector?

To assemble an M12 crimp field wired connector, follow these steps.

Step 1: Take all the housing components and push them onto the cable.

If there is an angled connector, move the angled housing in the cable by pulling the external thread.

Step 2: Prepare the cable.

Strip the cable. If the cable is A or D coded, strip approx. 18mm and is x-coded, strip 20mm. Make the braided shielding short up to 5-7mm.

Step 3: Crimp contacts.

Crimp the individual cable using crimping pliers.

Step 4: Assemble connectors.

- Start with the fifth contact first.

- Snap all other conductors using the proper color schemes.

- Slide on the contact carrier.

- Bring the braided shield and grading ring towards the front.

Once the grading ring snaps, push the braided shield on the grading ring. Now take the anterior housing sleeve and push it on the assembled part.

Step 5: Complete the assembly.

5a: Screw the straight housing to the assembled portion with the help of a wrench.

5b: Now, take the angled housing and screw it to the whole assembly and tighten the knurl. And then fix the angled housing with another straight housing.

Conclusion

Finding the right system with corresponding cables is difficult, but custom cable assemblies make things easy. If you are looking for overmolded cable assemblies for your applications, we can help you. And our experts can create sensor cables, the USB cable that perfectly matches your requirements.