On many occasions, you have to install the cables in the bend position.

Especially in massive data centers, where thousands of data cables cross over each other all over the place.

You must keep the wires as organized as possible to save space in such places.

Moreover, it will be easy to work with organized cables in case of maintenance or repair rather than immerse yourself in a pool of random wires.

However, while organizing the wires, you must be careful not to bend them beyond their radius.

A bend radius calculator can help you a lot, and let’s find out.

Table of Contents

- What is the Bend Radius?

- Common Types of Cable Bend Radius

- Fixed Cable Bending Radius Calculation

- Where Will You use Cables With a Tight Bend Radius?

- How to Make Cables With a Slight Bend Radius?

- Does the Bend Radius Change at Extreme Temperatures?

- General Rules and Recommendations for Selecting the Radius

- Conclusion

What is the Bend Radius?

The minimum radius at which the cables can bend without cable damage or cracking is the bend radius.

Beyond this measure, if you try to flex the cable, it may cause kinks or abrasions on the surface.

Moreover, such activity can also shorten the lifespan and disrupt signal transmission quality.

Additionally, the lesser the bend radii of a cable, the greater the bending ability of the cable.

For example, a particular CAT6 24AWG cable can bend by 25mm compared to CAT6 28AWG wire with a 15 mm bend radius.

In this scenario, 28AWG cable is more flexible and can fit into small spaces more efficiently.

Common Types of Cable Bend Radius

There are three types of cable bend radius that you will need for most of the applications,

- Fixed

- Flexible

- Chain

A fixed cable radius is needed for areas where you will install the cable once. In such applications, the cables do not have to move constantly.

However, in a flexible setup, the cables have to move freely. In such cable applications, you cannot define the number of bends.

The chain radius cable is specified when cables have to move continuously. But it is not a fixed measure; thus, you need to measure it in real-time applications.

Fixed Cable Bending Radius Calculation

Usually, the minimum bending radius depends on four factors;

- Insulation material of the cable

- Size of the cable

- Overall Diameter

- Construction of the wire (Bend angle/angle of bend, Neutral Axis, Bend allowance Flat patterns, etc.)

All of them decide on the cable type. For minimum bend radius, you can use the following formula.

Min. Bend Radius. = Outside Diameter (O.D) of your cable × Multiplying Factor

The formula is simple. Yet it would be best if you determined some factors upon which the calculations depend.

Hence, follow these steps to calculate the minimum bend radius accurately.

- First, see the type of cable that you are dealing with.

- Next, see whether the cable is a single-conductor or multi-conductor wire

- Now, check the voltage on your cable. Also, determine its insulation and shielding type.

- Here, you need to see if your cable can classify as a mining cable. Moreover, does it have Metallic Armor inside it?

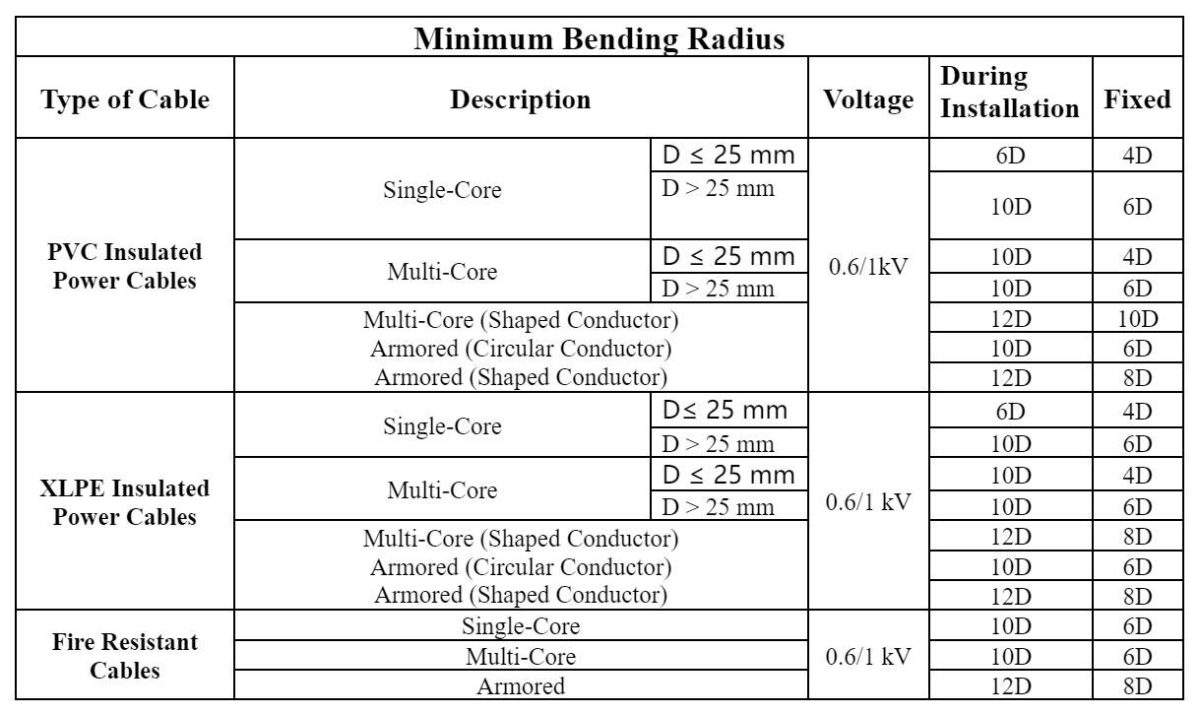

- After determining the type of your cable and all its specifications, you can now calculate the minimum bend radius. You can use the Outer diameter O.D of your wire and the multiplying factor as shown in the table below.

For example, in the case of Category 5 or 5e cables, the bend radius is eight times the cable diameter. So, suppose the diameter of a cable is 20 mm. In that case, you can calculate the bending radius as

Bending radius of a CAT5 cable=8D=8*20=160 mm

Caption: Minimum Bending radius of different cable Types

Where Will You use Cables With a Tight Bend Radius?

Cables with small bend radiuses are used in a wide range of applications. It is useful in applications where cables need to move in the shortest available space.

For example, you can use them in the electronics and assembling industry, robotics, automobile, and financial sectors.

Automated doors for trucks and trains, self-service meal vending machines, and packing sectors have new applications.

How to Make Cables With a Slight Bend Radius?

Copper cores in typical cables can quickly reach their high strain rate limits in different applications with small bend radii.

For added flexibility, manufacturers make the cable’s jacket of highly abrasion-resistant material, such as polyethylene terephthalate (PET).

Thus, you can use chain flex cables with the shortest bend radii for a longer service life for the cables.

Does the Bend Radius Change at Extreme Temperatures?

Temperatures do impact the radius of a cable, and that’s a fact.

You can calculate the minimum bend radius by the temperature range in which the bending occurs.

If the surface temperature surpasses the temperature range for the cable, you must take special precautions.

When exposed to freezing temperatures, the polymer becomes prone to cracking and may collapse.

Moreover, too high temperatures cause the material to become pliable, resulting in significant abrasion levels.

As a result, experts recommend that you utilize a cable with a TPE or a PUR jacketing designed for severe temperatures.

General Rules and Recommendations for Selecting the Radius

Here are some general recommendations to consider before selecting a bend radii.

Do not go beyond the manufacturer’s specified minimum radius – the maximum radius, on the other hand, is ideal.

For the most part, cables with elastic specifications that move need support to prevent shear loads on the contact points and the formation of a sharp bend.

Thus, use a ten times more diameter cable since the greater the bend radius, the less stress is placed on the wires, resulting in longer service life for the cables.

Remember that the minimum bend radius is determined by the temperature range in which the bending occurs.

Thus, as the ambient temperature reaches or exceeds this temperature range for the cable, you need to consider special precautions.

Mostly the temperatures become an issue in cryogenic cables, which can freeze at low temperatures, causing cable faults.

To avoid such failure at low temperatures, use cables with a PUR or TPE jacket and consult the cable manufacturer for bend radius guidelines.

The cable carrier radius must be shorter than the specified minimum bend radius for the filling pack for use in applications where space is limited.

It is not ideal, but cables specifically designed for short-bend radius installations should be employed if it is impossible to prevent.

Caption: Bended Cable bundles

Conclusion

The cable bend radius measures the minimum radius beyond which you cannot bend the cable.

Also, different types of cable have different numbers of multipliers.

Thus, they have different minimum bend radii.

Here at Cloom, we offer flexible wiring harnesses and cable assemblies. Your connection is made with attention to detail.