A vehicle’s engine is the most critical part which makes your vehicle functional. So, you must take care of all the engine parts and ensure everything is working perfectly. If your car is showing some errors, you should first check your wiring harnesses and decide whether to change them. The custom engine wiring harness may be your best option for replacing one.

Table of Contents

- What Is an Engine Wiring Harness?

- How does an engine wiring harness work?

- How do I know if my engine harness is wrong?

- Is it difficult to replace an engine harness?

- Engine Harness Replacement Cost

- Is it possible to fix an engine wiring harness that is not functioning?

- Why does my engine harness go bad?

- Conclusion

What Is an Engine Wiring Harness?

Engine wiring harnesses are a set of cables, wires, terminals, and connectors that control the electrical system of a vehicle. The engine wiring harness transmits electric power and sends information to different outlying components, including:

- Audio systems

- Batteries

- Alternators

- Computers

- Blower motor

- Fuel injector

- Windshield wiper

- Fuse

- Any other electrically controlled parts of the vehicle

The engine wire harness carries battery power to the fuel pump, ignition coil, alternator, starter, emission control component, and air intake system.

Image: engine wiring with a bundle of coolant tubes and corrugated pipes

How does an engine wiring harness work?

Imagine your car as a human body, and the engine wiring harness work as blood vessels for this body carrying electricity to all the car parts. The whole vehicle engine system works in the following steps:

In this whole system, the battery works as the heart. The alternator ensures that the battery has power and a part of the wiring harness takes this power to the fuse box.

The fuse box protects the whole engine system from the high current by stopping it. The engine wiring harness starts from the engine and goes to the fuse box. It then helps transmit the power to the starter, ignition coils, alternator, emission control components, air intake systems, and fuel pump from the battery.

Now, the wiring harness brings back the power to the vehicle engine and the different engine components such as the computer, wiper, blower motor, and others.

How do I know if my engine harness is wrong?

These symptoms will tell you whether your vehicle requires a new engine wiring harness:

- Malfunctioning indicator

- Illuminating lamp

- Irregular or hard start

- Warning light of the engine flashing or in “on” condition

- Random stalling out

If your vehicle faces any of these issues, address them immediately as they will be less expensive and more convenient at earlier stages.

Is it difficult to replace an engine harness?

The difficulty in changing an engine harness depends on the specific vehicle, and it can take either only up to one hour or can also take around 16 hours. Nowadays, cars are becoming highly dependent on electrical functions; thus, repairing is becoming more complex. Therefore, looking out for professionals to get your work done is essential.

Engine Harness Replacement Cost

Replacement of an engine wiring harness costs around $1,100. An engine harness will cost about $650, while the labor will cost about $575 for installation. The cost of the engine harness depends on the types of vehicles and their make year. Further, the car’s features, capabilities, and sensors.

Is it possible to fix an engine wiring harness that is not functioning?

If your engine wire harness does not have severe damage, you can fix that damage. For repairs, sometimes, you may need to repair some simple parts. If you want to assess whether your engine harness needs repairing or replacing, consider the points mentioned below:

Check the degree of the damage

Sometimes only some portions of the wire get damaged. In such cases, you must splice a snew wire section and set connections again. There is no need for harness replacement.

Check for any burn-out spots on the engine wire harness

You can fix the wiring harness’s burn-out spots if they do not involve any electric machinery. If burnout areas involve more than one wire, you may need to replace the whole harness.

Check for any loose connections.

Sometimes, the engine harness shows errors due to some loose connections. To fix these, you need to reseat the connector inside the housing. Remember, you can repair loose connections, but leaving them unattended can cause more significant problems.

Check for any wrong components.

If you want only some components, you don’t need to replace the whole one. You can custom parts of the harnesses. Manufacturers may need your old cable harnesses to know the length and placement of components. For example, if you want to replace the door lock relay or install an alarm, there is no need to cut or splice the wires, and you are only required to plug the component in the wiring harness.

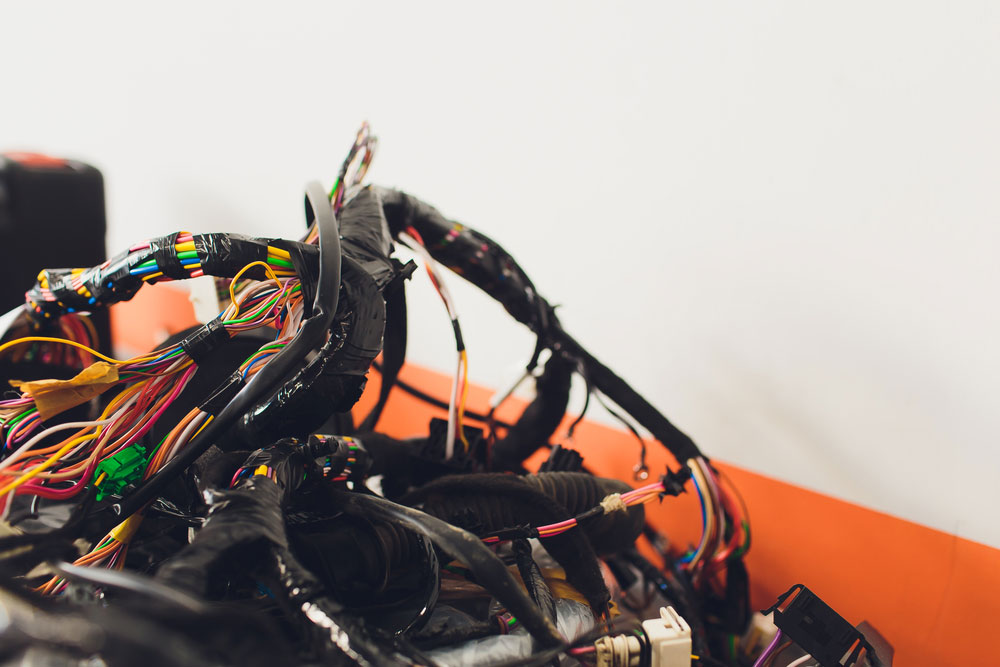

Image: automotive wiring bundle of wires

Why does my engine harness go bad?

Here are some reasons which can damage your engine harness. And knowing the causes will help you maintain the harness in a better way.

Short circuit

Sometimes, the engine harness faces an electrical short, which damages the whole engine harness. In such cases, it is difficult to identify the point of electrical short, and you may need to replace the entire engine wire harness.

Damage from water

If your engine has faced water damage, the wires in the harness will start malfunctioning. Further, the wires may get short due to moisture, leading to extensive problems. You may need to install a new harness after water damage.

Heat damage

Engine heating over a limit can happen when your car runs at its maximum rpm for a long time. In these cases, sometimes the harnesses also lead to electrical fires.

Weather conditions

The harness comprises a variety of materials, and in extreme weather conditions, even the best of the materials starts damaging. It may corrode and get damaged over time.

Image: car wiring

Conclusion

Great wiring keeps your car’s electrical system working perfectly. Remember that your vehicle engine depends entirely on a steady electrical source, and the wires that carry this electricity are the most important. So, it would help to choose an automotive wiring harness that can bear high temperature, shows resistance to abrasion and heat, and is rated for high voltage. In addition to this, don’t forget the small details kike connectors, switches, and terminals as they play a significant role in keeping the wires intact and functional.

If you want custom harnesses for your vehicles, contact Cloom. Whether for complex harness systems or simple harnesses, we provide customized wiring harnesses for our OEM customers. Give us the exact wire specifications, and we will provide custom wiring harnesses and fully integrated wire assemblies that you can plug and play with directly.