Many components that you use nowadays are based on complex features. Be its a weapon system, elevator controls, gear or control panel box, or printed circuit board conveyors; all use a mixture of electrical and mechanical parts. You might use a wire harness to provide a path to signals and electric power flow in a unit for such systems. All in all, electromechanical assembly is complex. You need to understand it and get the job done.

Table of Contents

- What are Electromechanical Assemblies?

- Types of Electromechanical Assemblies

- Industrial Applications of Electromechanical Assembly

- Who are Electromechanical Assemblers?

- What to look for in an Electromechanical Assembly Partner?

- Conclusion

What are Electromechanical Assemblies?

Caption: Electrician welding an Electromechanical System

From box builds to simple wire or cable subassemblies, anything in which the electrical and mechanical parts work together as a single and do a specific job is an electromechanical assembly.

In general, every machinery has its function to perform. Based on the functionality, you have to design and choose the parts of that heavy machine. Thus, the subassemblies and wiring components you will integrate will vary with installing them.

The assemblers will follow a blueprint that a specialist has created with attention to detail as the assembly process starts. Thus, they will connect the electric components with the mechanical part to make a single unit by observing.

Also, the person must be skilled in different aspects, including through-hole mounting, soldering, circuit layout, and surface mounting techniques. Additionally, these fabrication details will allow him to understand better the need and how any electrical or mechanical component can fulfill it.

Types of Electromechanical Assemblies

As you know, there are specific electromechanical assemblies to support a particular cause. However, below are some common types you will need in most cases. If not, you can customize the Electromechanical devices according to your needs.

Panel Assembly

You might find some assemblies in the form of panels. These usually serve as controllers for the power distribution units. Hence, you can handle the electric flow in different electrical parts through the panel assembly.

The creation process of such kinds of assemblies is straightforward.

- First, position the parts on the back panel. Make sure that you integrate them at the correct location.

- Then, punch or saw holes for each component to have a secure connection.

- Next, drill holes for fixing the hardware on the panel board.

- In the end, wire all the components of the panel.

Switch and Sensor Assembly

Switch and sensors are two different components with different functions. A switch assembly makes or breaks a connection in a circuit. At the same time, a sensor senses the stimuli like motion, heat, and light and converts them into electrical signals.

Since they both are different in performance, they have various components. A switch is based on

- Contact to control the flow of signals.

- Wiring harness to hold the switch in place and provide a path to the current for entering or exiting the switch body

- Switch mechanism to control the device operation (Usually a button)

However, a sensor has

- Sensing elements to detect the stimuli

- Housing to protect the sensing element

- Transmitters to transmit the data

- And connection heads connect the sensing wires to the transmitter

Transformer Assembly

Transformers can transfer the electric power between two or more electrical circuits. For that, they use fluctuating voltage levels and, as a result, produce changing magnetic waves. However, the extent of the activity will vary depending upon where you are applying it. The components of a transformer assembly are

- Laminated CoreWindings (primary and secondary)

- Insulations (PVC or others)

- Accessories (that you will need for a specific application)

Caption: A powerful transformer for supplying energy

Power Supply Assembly

On the other hand, a power supply assembly will provide an electrical load. Thus, the unit converts the electrical energy into the current and voltage a receiver requires. That way, they will power up the system.

Power supplies can be a part of a more extensive assembly or a device on its own. Components of a power supply are

- Housing Case to insulate all the components

- Transformers that can change the voltage levels into the required ones

- Rectifiers that convert the power from AC to DC

- Filter to smooth the power waves in DC power

- And Regulator to reduce the ripple effect in the voltage due to filtering

Caption: Power Line for a sector

Cable Harness Assembly

Cable Harness assembly has cables and wires connecting the system and transferring electrical signals. These components are

- Wires and Cables that carry the power

- Connectors that connect the wires to devices and other cables

- Fuses that can prevent the heavy flow of current

- Relays to power on or off in High power circuits

- Insulation material to insulate the electricity carrying components and

- Ties to fix the wire harness.

DIN Rail Assembly

You can use the Mounting Rails or DIN rails to mount the components inside the assemblies. Thus, you need to choose and configure these rails according to the parts or subassemblies of the unit.

Industrial Applications of Electromechanical Assembly

You can find electromechanical assemblies in various industrial equipment and systems. But, some industries use them the most.

- Aerospace needs custom designs for incorporating preciseness and unique features in different aircraft systems. Therefore, the electromechanical assemblies are present in power boxes, switch panels, cockpit panels, etc.

- Automotive, since you need reliability along with long-term functionality in an automotive system, you will find electromechanical components in sensors, relays, and switch boxes.

- Military includes from simple wire harnesses to complex panels

- Agriculture, where you will find the assembly in tractors and sprayers since the work calls for switches, etc.

- Fire Protection, which again uses a sensing mechanism. Thus, you will find electromechanical sensor assemblies in critical places like hospitals, schools, and other public (or private) places.

- Heavy Equipment, since the vehicles depend on box builds, wire harnesses, and other assembling for high performance in harsh environments.

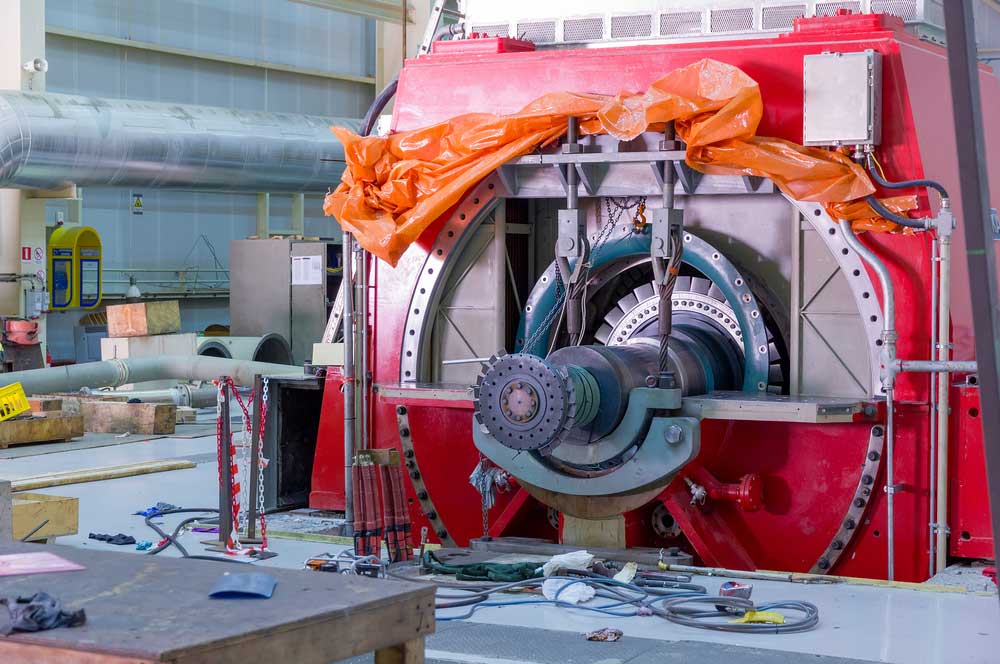

Caption: Heavy machinery under construction

Who are Electromechanical Assemblers?

Electromechanical assemblers are the ones that perform the assembling tasks in machinery. Hence, they put together the electrical and mechanical parts to create a meter, controller, or actuator.

Rather than just fixing the components, they will also require performing unit tests, interpreting drawings and blueprints of a system, drilling holes, and creating units out of different elements. Also, you might need to use hand tools for connecting wires and buff or file parts until they are a perfect fit.

What to look for in an Electromechanical Assembly Partner?

One cannot deny the importance of the assembling process. Therefore, it is essential to be careful while choosing a person or a company to outsource your task.

So, you will need a partner that

- Has the resources and skills that he can help you in designing a new system or validating the old assembly

- Can provide you with detailed documentation, which includes details of each step

- Has tools to create prototypes so that you can evaluate their effectiveness.

Caption: Mechanical assembler testing unit

Conclusion

Electromechanical assembling incorporates electrical and mechanical components. However, every application needs a different way of assembly. Thus, you need to hire a professional Electromechanical Assembly Partner. Here at Bloom, we offer a wiring harness, so your connection is made with attention to detail.