As we all know, fuses are an essential component of any circuit since it helps in preventing short circuits and other hazardous effects. Now, you can add an inline fuse parallel to each circuit component or in series with the whole loop. Do you know how the inline fuse works? Let’s dig into the inline fuse wiring.

Table of Contents

- What is an Inline Fuse?

- How Do Inline Fuse Holders Work?

- How to Wire an Inline Fuse Holder

- Thermal Factors to Consider

- Conclusion

What is an Inline Fuse?

A fuse is a circuit-breaking security device that you can add to a circuit’s wiring. It usually works in a circuit’s “path,” according to the technical definition. Also, you can achieve fuse protection by limiting the amperage (the amount of current) of electrical power that can flow through the fuse. The fuse will blow if the wind is too high. It will prevent harm to the circuit’s electrical components.

There are a variety of techniques for installing fuses. You can find some of them in the electrical panels of the fuse box. In contrast, inline fuses do not require a separate fuse box. Thus you can fit them wherever a circuit needs protection. Autos, solar panels, home theaters, and other electronic devices all employ inline fuses. They prevent overcurrent from causing harm as you place them between an electrical supply and an appliance.

Caption: Electrical fuse for Overload protection

How Do Inline Fuse Holders Work?

Typically, you’ll find the fuse rating in amps on the side of the fuse. A fuse rating is the amount of current required to blow or open a fuse. When this happens, it stops power from flowing through the circuit. Fuse ratings are valuable information and should not be ignored. Each course requires a different amount of current, and there may be too much or too little current to fit in one circuit.

Here’s how to choose the correct fuse size in 3 easy steps:

- Find the wire gauge you are using by measuring or placing it on the package.

- Use the table below to determine the maximum current for any wire gauge.

Source:https://www.oznium.com/blog/how-to-determine-the-fuse-wire-size-for-your-project/

- Take the maximum current value from the table and find the largest fuse within limits. Common automotive blade fuses are 5A-20A in 5A increments. For example: 5A, 10A, 15A, & 20 Amp Fuse.

A fuse with an inline placement usually has a two-part holder. This holder wires into the circuit itself. For example, the line will be severed if you use a cable to complete the course. After that, attach each holder section to the cable’s exposed end. After setting up the holder, you can tuck the inline fuse inside. The circuit’s electrical components won’t function properly if you do not add one on time.

Also, you can use both screws and snap styles for inline fuse holders. Depending on the design, you can screw or clamp the two halves together after inserting the fuse.

Caption: Clear electrical Fuse

How to Wire an Inline Fuse Holder

Fuses protect against a single surge of electricity. And you have to replace the fuses whenever they fail. Perform the steps below to replace the fuse in the event of a failure.

Material

When properly installing inline fuses, you will require some supplies to assist you in doing the work to the best of your ability. These are

- Compatible AWG Wire

- a pair of pliers for stripping and cutting wire,

- crimping pliers,

- butt-splice crimpers,

- a fuse holder with the proper amperage rating.

Steps

As you have all of these items, installing an inline fuse holder is as simple as following these procedures in the correct order.

- Remove the power supply from the device you are using.

- Snip the positive red wire closer to your wiring using the pliers for cutting gauge wire.

- Using the cable-stripping pliers, remove a quarter of an inch from each end of your split cable and the end of the holders. When removing the insulation from the wires, be careful to grip them tightly so that you do not harm the inside of the inline fuse.

- Make the naked ends of your circuit wires complex and straightforward to connect by winding them into a spiral before joining them.

- Here, it would help if you used crimping pliers to press down to the end of the fuse holder cables after you insert them into the opposite end of the connector. Check the connection to see that you have adequately secured the ends.

- Now, twist the primary device wire and insert the twisted end inside a butt splice connector as the wire is clamped down.

- Turn the other end of the holder so that it is facing away from you, then put it into the butt splice with system wire and crimp it down.

- Put the fuse with the correct amperage rating into the holder for fuses. Then join the two pieces of the holder by pressing them down and locking them into position.

- Restore the device’s power supply and test whether the fuse is working or not.

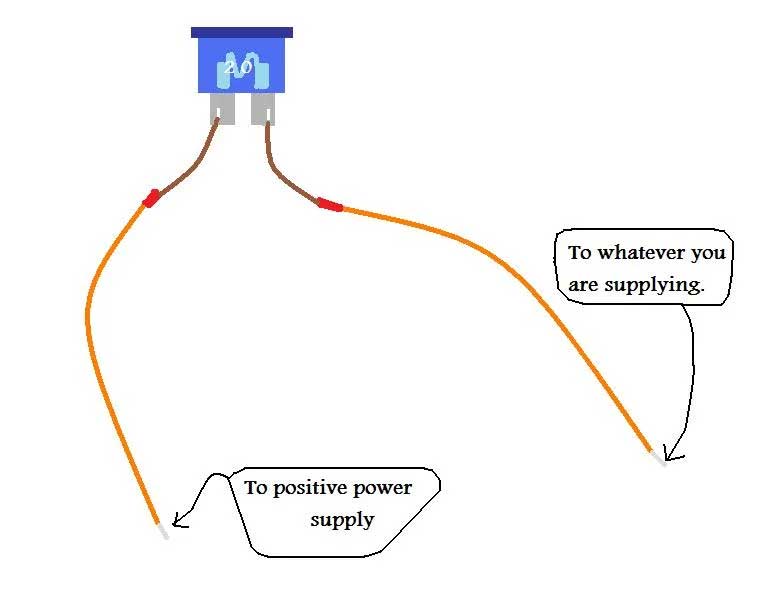

Caption: Inline fuse wiring diagram

Source: https://www.instructables.com/simple-in-line-fuse-for-your-car-or-any-12-volt/

Thermal Factors to Consider

The designer must consider ambient temperature and heat rise in the application area when using fuse holders. It helps in choosing the most appropriate components for the applications at hand. Moreover, it allows them to determine whether or not the design needs to be expanded to help alleviate issues with heat buildup. Hence, It is essential to pick the correct fuse and fuse holder combination for the job. The engineer is responsible for ensuring the power confirmations and temperatures.

Included in the list of things to think about are:

- The consequence of power loss in the connection points of the fuse holders

- The power dissipation rating of the fuse

- Fuse holder dimension

- Fuse wires/fuse holder wires/fuse holder cable type

- Fuse holder operational current, temperature ratings, and acceptable power acceptability

- The temperatures of the air surrounding the equipment, both inside and outside of it

- Changing the load on the electrical system

- Heat impacts of neighboring components caused by continuous operation with a burden more significant than 0.70 In.

- The apparatus consists of heat dissipation and cooling parts, and ventilation components.

- Bringing together the wire’s length and its cross-section.

- The orientation of the mounting hole in the fuse holder.

Caption: automotive fuses on

Conclusion

The inline fuse prevents the fluctuating current from flowing from the path. You can wire it using a butt splice and crimp the wires with a crimping tool. However, Choose a suitable fuse and fuse holder after considering these considerations.

Following this, we suggest that the selected devices be put through rigorous testing in the most demanding of environments. Problems that point to excess heat may demand a different approach or tweaking the current design. Here at Cloom, we offer wiring harnesses and cable assemblies to make your connection safe and reliable.