Electric power distribution carries electricity from the transmission system to the consumers. The power distribution units are either underground or overground. In urban areas, it is underground in common utility ducts (sometimes), and in rural areas, it is with utility poles and above the ground. However, in suburban units, it is a mix of both. No matter which type you choose, you need to pick the right cables, and the proper selection ensures smooth and reliable operations. Today, in this article, we will get into details about the power distribution cable.

Table of Contents

- Power Cables and Your selection

- Construction of power cables

- Power Distribution Cable–Underground and overhead cables

- Power Distribution Cable–Recent Developments in Cable Technology

- Conclusion

Power Cables and Your selection

The cables that you use for the transmission and distribution of power are power cables. The designing and manufacturing of these cables depend on the maximum operating temperature, rated current, and the application’s power requirements.

Construction of power cables

A power cable comprises the following parts:

Conductor:

Conductors are the innermost and essential part of a cable, and they carry current to the cable destination. Copper and aluminum-based conductors are the best due to their high conductivity. Other materials such as copper alloys, cadmium, phosphor bronze, steel core, and galvanized steel are also used as conductors nowadays. The conductor size depends on its resistance. You can use stiff, non-flexible conductors to highly flexible conductors based on the application requirements.

Insulation

Every conductor has insulation covering to prevent faulty currents from flowing outside cables, and insulations are of different types. Further, the insulation type depends on the cable’s current and voltage ratings.

Image: electric power transmission with high voltage power lines

Beading

The beading process offers extra mechanical strength to the cable. Additionally, it also provides earthing protection to the thread.

Power Distribution Cable–Armoring (optional)

In contrast to unarmoured cables, armoring provides earthing protection to the current-carrying conductor, as the faulty currents flow through the armor if insulation fails.

Outer sheath

This outermost layer protects a cable against mechanical, weather, chemical and electrical stresses. Materials such as PVC (polyvinyl chloride) or different types of rubber form this outer sheath.

Power Distribution Cable–Underground and overhead cables

As the name suggests, an underground cable lies beneath the ground while an overhead line is visible over the head. Apart from this difference, there are many other features of both wires based on the electric power distribution.

Power Distribution Cable–Overhead cable

You can call overhead cables the bare conductors also. These cables have been in use for electrical transmission for decades. To commission these cables, you need to install towers and poles. These cables are generally in the form of bare wire conductors. Mostly, aluminum and its reinforced forms are in use. However, medium voltage and low-voltage cable systems use copper wires also.

These cables are bare and overhead, constantly facing adverse environmental conditions. These may be heavy rains, snowfall, high heat, and humid conditions. As a result, the lifespan of these cables becomes less. Also, the weakening of these cables causes serious safety concerns.

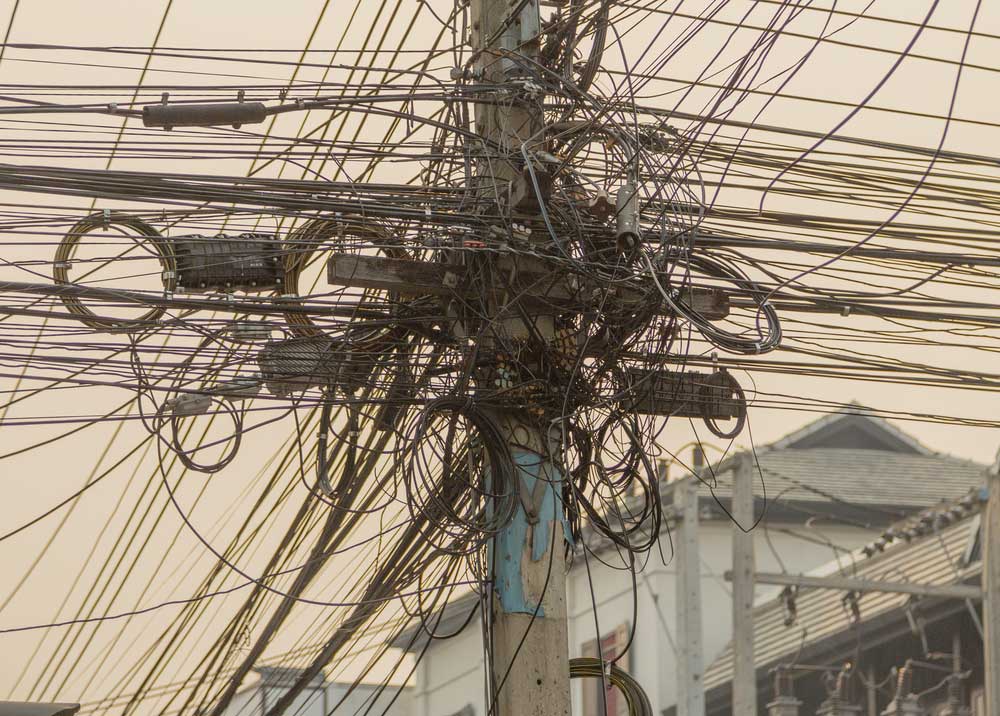

Image: overhead power telephone and internet cables

However, along with this, the overhead wires also offer several advantages such as:

- Need for less insulation

- Easy fault detection

- Less cost of installation

- Easy to expand

- Independent of proximity effect

- The small size of the conductors

- Higher life expectancy

Demerits of overhead lines:

- Non-aesthetic in appearance

- Radio interference due to corona discharge

- Emits hiss/hum noises every time

Power Distribution Cable–Underground cables

These are appropriately insulated cables that are lying under the ground.

These cables also offer several advantages such as:

- Firstly, they provide a continuous power supply.

- Secondly, these cables incur lesser faults as they do not face any adverse conditions like rain, heat, wind, etc.

- Thirdly, there is no radio interference.

- Finally, there is no need for transmission towers except for the local transformers.

Image: laying of wires and pipes in the trench

Along with the advantages, these cables also have their setbacks. These include:

- Challenging to locate any damage.

- Repairing and restoration of the faults take more time.

- You need more cables in underground systems for the same capacity compared to overhead cables.

- To construct an underground cable system, you need duct banks, splices, vaults, and terminations. All these lead up to the high cost of underground cables. It also makes the system less reliable. This problem increases with the increasing length of the cable.

- Heat dissipation from the underground cable systems may also interfere with its successful operations.

Power Distribution Cable–Recent Developments in Cable Technology

Underground cable systems are becoming more popular and reliable. However, you cannot ignore its shortcomings. Thus, many high-tech innovations are coming in cable constructions to overcome their negative issues. The main focus lies on voltage grade and insulation. Today, we have high- and better-quality polymers due to several advancements in the field of material science. These polymers have desirable electrical and mechanical properties.

Some of the developments include:

- Teflon cables can withstand a high temperature of 250 degrees Celsius, which PVC cables cannot.

- Several alternatives to copper are available today, which are much more affordable than copper.

- Some cables can operate even at a high voltage of 440kV.

Overhead cables have also experienced some similar kinds of products. After these developments, the cable industry now has a wide range of wires based on

- Conductor types: Different conductors include AAC (All Aluminium Conductors), ACSR (Aluminium Conductor Steel Reinforced), ACAR (Aluminium Conductor Alloy Reinforced), AAAC (All Aluminium Alloy Conductor), AACSR (Aluminium Alloy Conductor Steel Reinforced).

- Voltage rating: cables that operate at different voltage ratings like

- 132kV to 220kV

- 221kV to660kV

- Greater than 660kV

- Mechanical strength: cables with different mechanical strengths

- high strength

- extra high strength

- ultra-high-strength

- Types of current: cables for HVAC and HVDC currents

- Types of application: cables for High Tension, Extra High Tension, and Ultra High Tension

All these developments will take cable technology to a new level. These advanced cables bring power distribution solutions to a wide range of customer requirements.

Conclusion

A power distribution system should be reliable, safe, and economical. The cables in the system play a significant role in this. Thus, you always need to pick a high-quality line to avoid serious accidents. For any queries about cable solutions, please contact our experts. We can provide you with superior ones.