Imagine that an exposed wire connects to a primary power grid, causing deadly accidents. So, it would help if you used an insulated wire in your wiring applications. However, different variations make it challenging for people to choose the proper one. This blog will get you to know different wire insulation types. Using this information, you can decide which electrical cable suits your application.

Table of Contents

- What is Insulated Wire?

- Types of insulation

- Conclusion

What is Insulated Wire?

Insulated wires are conductors covered and held together by wire insulation. And insulation is a critical safety component. Its purpose is to keep the electrical current from the cables contained.

Depending on the electrical conductor and insulation, a wire can be different. Mainly, a conductor is made of copper or aluminum. However, copper is the better option.

Earlier, insulated technology comprised braided sheaths and knob and tube systems. Nowadays, engineers use complex polymers rather than rubber to protect wires.

Generally, engineers change insulation to overcome the harmful properties of the old insulation.

- First, an insulating material must not get brittle with age.

- Second, an insulating material must not lose its solid characteristics and convert it into liquid.

- Third, an insulating material must not lose its flexibility over time

- Fourth, the properties like heat resistance of insulation must not change over time

- Also, When used in cryogenic HVDC applications and freezing climates, insulating material should be resistant.

- Lastly, an insulating material must be UV light resistant and not break under sunlight.

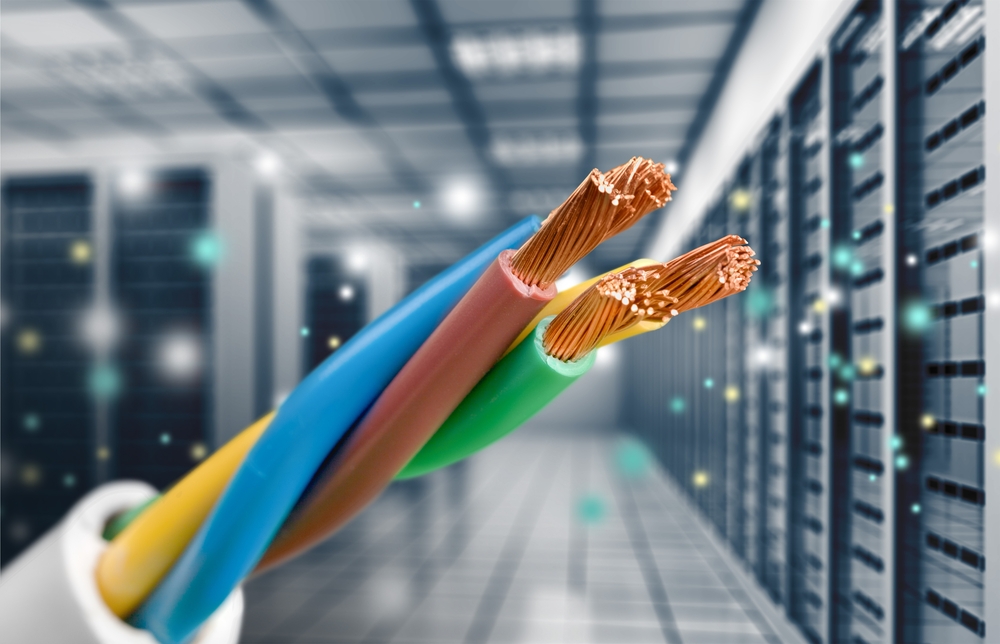

Image: four core armored copper cable

Types of insulation

The three most common materials used for wire insulation are plastic, rubber, and Fluoropolymer.

Plastic Insulation Types

PVC or polyvinyl chloride:

- It is easy to use in different applications, including heavy and thin-wall applications.

- Is an inexpensive insulation material.

- It can withstand a temp range of -55 degrees Celsius to +105 degrees Celsius.

- It is resistant to flame, abrasion, and moisture. Also, it can bear the exposure to ozone, acids, solvents, and gasoline.

- It is odorless, tasteless, and non-toxic. As a result, you can use it for medical, food, and other household applications.

- As PVC lacks flexibility, it is unsuitable for long flex life applications.

- It has high attenuation and capacitance loss when using it in an electrical system.

SR-PVC or semi-rigid PVC

- It is the primary insulation material as it has abrasion resistance.

- SR-PVC has flame retardant properties. Thus, it is resistant to water, acid, heat, and alkali.

Plenum Polyvinyl chloride

- You can use plenum PVC in plenum spaces. These spaces are open for air circulation behind raised floors and dropped ceilings. The plenum PVC meets more strict fire safety regulations.

Polyethylene

- It has classic electrical properties and is suitable for low capacitance and coaxial cables.

- This insulation material is affordable.

- You can reduce its dielectric constant to 1.5 by foaming. Thus, you can use this in cables needed for high-speed transmission.

- Professionals also cross-link PE to make them more resistant to cracking, soldering, solvents, and cut-through.

- You can use them in the temperature range of -65 degrees Celsius to +80 degrees Celsius.

- PE is stiff, inflexible, and rigid.

- Although PE is flammable, additives can make it flame retardant. However, it loses its dielectric strength.

Image: coaxial TV cable

PP or Polypropylene

- It is like polythene but with a broader temperature range of -30 degrees Celsius to +105 degrees Celsius.

- One can improve its electrical properties with foaming.

- It is suitable for use in thin-wall primary insulations.

PUR or Polyurethane

- It shows extreme toughness and flexibility even under low-temperature conditions.

- In addition to this, it also offers resistance to chemicals, water, and abrasion.

- PUR is suitable to use in retractile applications. Further, it is also a good option for salt spray and low-temperature military applications.

- PUR is mainly flammable. However, additives can make it flame retardant, losing its strength and surface finish.

- Due to its poor electrical properties, it is more useful in jackets than in insulation.

Chlorinated Polyethylene (CPE):

- CPE has high oil, heat, and weather resistance.

- It serves as an alternative to CSPE as it has lower costs and is more environmentally friendly.

- As it is highly fire-resistant, it also serves as an alternative to PVC insulation.

- As a result of its fire-resistant property, you can use this in power and control cables and industrial power plants.

Nylon

- Nylon is highly resistant to abrasion, cut-through, and chemicals, mainly in thin-wall applications.

- The nylon jacket is quite tough, and it extrudes over softer insulation materials.

- It is very flexible.

- As nylon absorbs moisture, it loses its electrical properties over time.

Rubber Insulation Types

Thermoplastic Rubber (TPR)

- Sometimes, in several applications, TPR replaces thermoset rubber.

- High processing speeds, a wide temperature range, and better colorability.

- Also, it is resistant to water & weather and has a long life. However, it is not resistant to cut-through.

Neoprene (Polychloroprene)

- Synthetic thermoset rubber.

- Need vulcanization for better qualities.

- Highly resistant to abrasion, oil, solvents, and cut-through.

- Has long life, wide temperature range, and higher usability.

- It is self-extinguishing and flame retardant. Thus, it is suitable for hand-held cord devices and military products.

Styrene-Butadiene Rubber (SBR)

- Thermoset rubber with similar qualities as that of Neoprene.

- Wide temperature range of -55 degrees Celsius to +90 degrees Celsius.

- Suitable for Mil-C 55668 cables.

Silicone

- Silicone rubber is a highly flexible, heat-resistant, and flame-retardant material.

- As a result of the above property, it can withstand temperatures up to +180 degrees Celsius.

- Also, it is moderately abrasion-resistant.

- Silicone has a long life and impressive bonding properties. Thus, it has been a part of many electrical applications.

Fiberglass:

- Most common glass insulation.

- Suitable for temperatures up to +482 degrees Celsius.

- High resistance to moisture and chemicals.

- Suitable for aluminum processing applications, including heat treating, foundries, glass, and ceramic kilns.

Ethylene Propylene Rubber (EPR):

- Have excellent electrical and thermal properties.

- Resistant to oxidation, heat, chemicals, oil, water, acid, alkali, and alcohol.

- As EPR is flexible, the mining industry and temporary installations use it.

- High voltage cables use this insulation material.

- Wide temperature range of -50 degrees Celsius to +160 degrees Celsius.

- As it is not tear-resistant and is soft, you may need to be careful during installation.

Chloro-sulfonated Polyethylene (CSPE):

- Suitable for low voltage cables.

- can perform well in a wide temperature range

- Resistant to chemicals and UV rays.

- You can use it in motor lead wire, transformer leads, coil leads, and appliance wire.

Ethylene Propylene Diene Monomer (EPDM):

- Excellent resistance to heat, weather, abrasion, and ozone.

- Exhibits good electrical properties, including good dielectric strength

- Highly flexible at low and high temperatures, i.e., from -55 degrees Celsius to +150 degrees Celsius. Thus, it replaces silicon rubber in some applications.

Fluoropolymer Insulation Types

PFA:

- The temperature range of PFA varies with cable construction. It can vary from -65 degrees Celsius to +250 degrees Celsius.

- Its low dissipation factor makes it suitable for electrically efficient use.

- It does not have thermoset qualities to use in only some selected applications.

Polytetrafluoroethylene (PTFE):

- It is a thermoplastic material and has a temperature range of -73 degrees Celsius to +204 degrees Celsius.

- Its properties include high flexibility, and resistance to water, chemicals, heat, and oils.

Fluorinated Ethylene Propylene (FEP):

- Its processing characteristics make it suitable for plenum cable and military applications.

- When foamed, it has improved the transmission of data.

- It also has high flame resistance.

ETFE and ECTFE Halar:

- Compared to PFA and FEP, ETFE and ECTFE have more strength and higher flexibility.

- With foaming, ECTFE and ETFE have better signal transmission.

Polyvinylidene Fluoride (PVDF):

- Extremely flexible, light in weight, and thermally stable insulating material.

- Highly resistant to heat, weather, abrasion, chemicals, and fire.

- As it is low-cost, it is favorable for various industrial applications.

- Cables that pass UL standard 910 Plenum Cable Flame Test use PVDF insulation.

Conclusion

Remember, extra insulation gives different properties to the enclosing conductors. And choosing the correct proper one can be challenging. However, you can get help from professionals from Gloom.