In every building, you need to install wires and cables for electrical needs. You must ensure a high-quality selection of lines for a safe electrical connection. There are different criteria on which you select the electrical wires. One of them is wire thickness, also known as Gauge. Wires of different gauges solve other purposes. In this article, you will read in detail about the wire gauge chart.

Table of Contents

- What are wire gauges?

- AWG Formulas

- Relationships Between Wire Gauge and Other Technical Specifications

- Wire Gauge Size Chart

- Stranded wire AWG Sizes

- Typical Applications of Standard Wire Gauges

- Choosing the Perfect Wire Gauge

- Conclusion

What are wire gauges?

The Gauge of an electrical wire means the thickness of the wire. A certain number represents the Gauge. The higher the number, the thinner the wire is. Industries use the American Wire Gauge method to measure the thickness of a wire. The AWG method is a standard method developed in the United States. With this method, you can specify gauges for solid, nonferrous, and round electrically conductive wires.

Image: different colored wires

AWG Formulas

According to the American Wire Gauge (AWG) method, the highest Gauge of a wire is Nr. 36 AWG, and the smallest Gauge is Nr. 0000. The diameters of these two are 0.005 inches and 0.46 inches, respectively. There are 40 gauges between these largest and smallest sizes, or you can say 39 steps. The ratio of these two diameters is 1.92. Now, as the gauge number decreases, the cross-sectional area increases. As a result, the diameter increases with the falling gauge number.

Now suppose A and B are two successive gauges, and their diameters are dia A and dia B. so, for these two, the diameter ratio is 1.12293. In contrast, the percentage of diameter for gauges two steps apart is (1.12293) ² ≈ 1.26098.

To calculate the diameter of an AWG wire, you can use the following formula.

dn=0.005inch*92(36-n)/39= 0.127mm*92(36-n)/39

Here n (from 36 to 0) is the AWG size, the value of n=-1 for Nr.00, n=-2 for AWG 000, n=-3 for AWG 0000.

To calculate the wire gauge with the help of diameter, you can use the following formula.

Step1– In this, you will calculate ratio R. The R is the ratio of wire’s diameter to that of standard Gauge (AWG#36)

R=d(inch)/0.005inch = d(mm)/0.127mm

Here, d(inch) is the diameter in inches, and d(mm) is measured in mm.

Step 2– Now, you can use the following logarithm o calculate the American Wire Gauge number (n).

n= -39log92(R) + 36

Relationships Between Wire Gauge and Other Technical Specifications

The wire’s thickness affects its electrical properties. Thus, with the help of a wire’s Gauge, industries identify whether a wire is suitable for their application or not.

Diameter: Wire gauges may vary from lower to higher numbers. A small number means a large diameter, while a large number refers to a small diameter. For example, the diameter of AWG 4 is larger than the diameter of AWG 40. The wire diameter doubles when the Gauge decreases by six levels, and it means a four-gauge wire will have double the diameter of a ten-gauge wire.

Area: You can calculate the cross-sectional area of a wire with the formula A= πr2. Here r is the radius (half of the diameter) of the wire. As the Gauge descends three levels, the cross-sectional area doubles.

Feet per pound: It means how many feet of wire you will need to reach the one pound of weight. For example, AWG 40 needs 34.364 feet to get one pound of weight.

Resistance (Ohms/1000 feet): The wire’s electrical resistance depends on the thickness and the length. The longer the wire, the higher the resistance. If the two wires are of the same size, the thicker wire will have higher resistance than the thinner wire. For example, AWG 4 has a resistance of 0.2485 ohms for 1000 feet, while AWG 40 has 1079 ohms resistance for 1000 feet at 25 degrees Celsius.

Current capacity (in amps): The current capacity is the amount of existing a wire can safely carry. The cables with lower gauges (AWG 4) are thicker and thus have high current capacity.

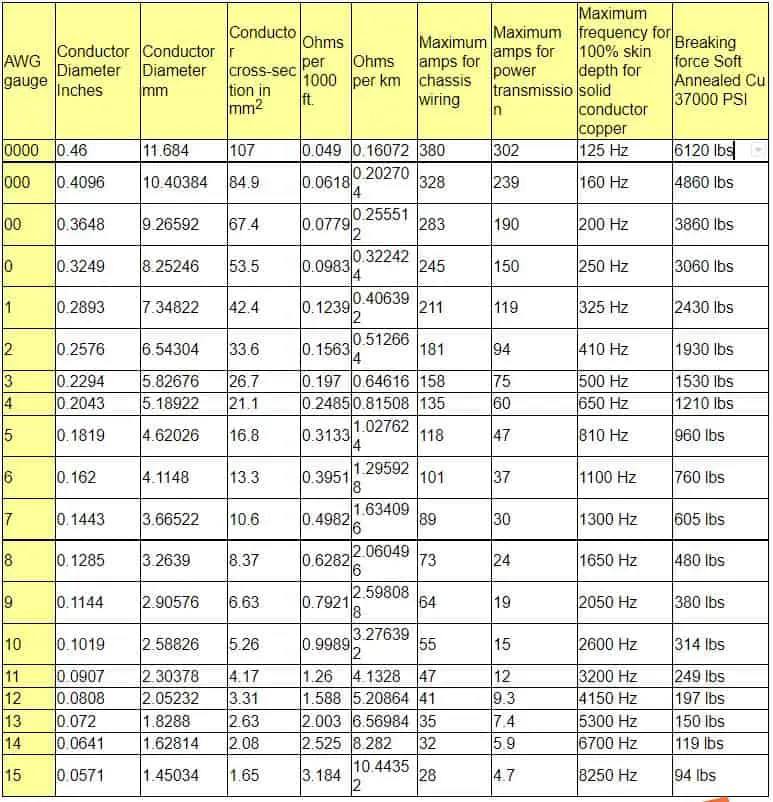

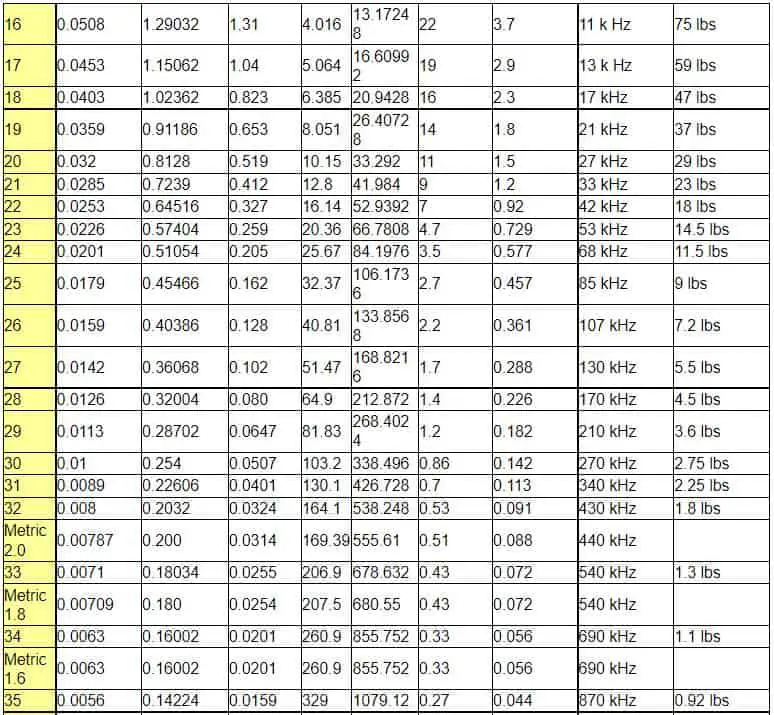

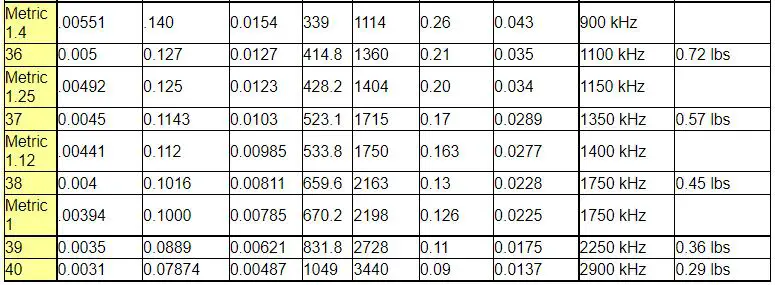

Wire Gauge Size Chart

The American Society for testing and materials (ASTM) maintains the standardization of wire diameters and cross-sectional areas. To see the latest wire gauge chart, you can see ASTM B258-18.

Stranded wire AWG Sizes

You can also use AWG gauges to describe stranded wire. For a stranded wire, the AWG gauge is the sum of the cross-sectional areas of each strand. Here, you do not count the gap between each strand. If the stranded wire is made of circular strands, holes consist of 25% of the wire area. Thus, the diameter of the overall bundle is 13% more than an equal gauge solid wire.

To specify a stranded wire, you have to mention three numbers. These include AWG size, the AWG size of the strand, and the number of strands. For example, a 22AWG 7/30 indicates a stranded 22 AWG wire with seven strands of 30AWG wire. To separate the number of strands and AWG of a single strand, you use a slash.

The difference in AWG affects the ratio of diameter and area. You can use this property to find the AWG of a stranded wire through diameter and number of strands. However, you can use this for a bundle of identical circular strands.

Image: the copper strands of large wires

Typical Applications of Standard Wire Gauges

The wire with different gauges has different electrical properties, and as a result, they are suitable for their unique applications.

Higher gauge wires are fit for lighter-duty electric works. On the other hand, lower gauge wires are suitable for heavy-duty projects.

For construction and building projects, the standard wire gauges used are 10, 12, and 14.

Some other applications of the wires with different gauges are-

- 18-gauge wire: you can use this for low-voltage lighting applications and cords

- 16-gauge wire: this is perfect for light-duty extension cords.

- 14-gauge wire: you can use it for residential wiring household outlets, electrical devices, and light fittings.

- 12-gauge wire: you can also use this for residential wiring, including small AC units and other appliances.

- 10-gauge wire: as this is thicker, you can use this for larger household appliances like water heaters, clothes dryers, or Window AC units.

- 8-gauge wire: you can use this for electric ranges and ovens.

- 6-gauge wire: a six-gauge wire is best suited for the largest household appliances, kitchen cooktops, and AC units.

- 4-gauge wires- best for furnaces and large heaters

Choosing the Perfect Wire Gauge

To choose the perfect gauge wire for your application, you must consider the carrying capacity and the current in amps that the wire needs to conduct. The current you need to run through a wire is directly related to the wire gauge.

Further, the distance of the wire that you need also affects the wire gauge. As there is no perfect conductor, you lose voltage with distance due to heat or resistance. To counteract this effect, you must choose a wire with a larger gauge. The high Gauge of the wire will increase its amperage capacity. Thus, you can pump required amps without experiencing any dip in voltage.

Conclusion

For an electrical system to run in the desired manner, it is essential to pick the correct wire. As a rule of thumb, the Gauge is a crucial factor. However, determining the right wire size is a bit complicated. You may take the help of professionals. You can contact Cloom for any assistance with wiring harnesses and cable assemblies. Feel free to call us anytime!