A wire harness is critical for the connectivity of the automotive structure, and you have to ensure the electrical insulation by choosing the right type of wire cover.

Consider an engine wiring harness. The more you drive your car, the more often the engine gets hot from “cold” to “operating” temperature. Although It’s inevitable, it raises an important question: how could wires be protected from constant engine heat exposure and direct interaction with hot components?

The solution is straightforward: use heatproof wiring insulation and perhaps even heat-protecting sleeve material that can endure direct interaction with high-temperature surfaces. Moreover, it must be a material specifically designed for structured system automotive applications and resist a constant temperature range of 125°C (257°F).

However, that’s not all. The automobile harness is divided into two functional lines: a power line for the actuator and a signal line for the sensor input command. They have different physical characteristics and need other covers.

Thus, Let’s see the common types of wiring harness cover available in the market.

Table of Contents

Types of Wiring Harness Cover

Every type has its application and purpose. Thus, you cannot use one in place of the other.

Cable sleeve

Caption: Cable Sleeving made up of mesh

Cables sleeves are made up of mesh material. So they can save you wires even if you bound the wire bundles irregularly. Also, as you want to cut it with a hot knife, you can seal its edges and avoid fraying.

The purpose of cable sleeves are straight, and they will

- Organize the wires, making the area more spacious.

- Protects the wires from temperature, moisture, cuts, and dirt.

- It prevents the current from flowing to the other conductors in contact.

Further, three options are available: Expandable, Self-closing, and Thermal protectant sleeves.

Most of these materials use polyphenylene or polyester as manufacturing materials. They offer open weave construction that makes the expandable sleeve easy to install and are flexible and make an easy-to-carry bundle. However, it might dissipate heat and moisture in electrical systems.

The self-closing wrap is non-expandable but is easier to install and maintain.

Moreover, you can choose the thermal protection option, a high-temperature wire sleeve that applies to critically hot areas of cable harnesses.

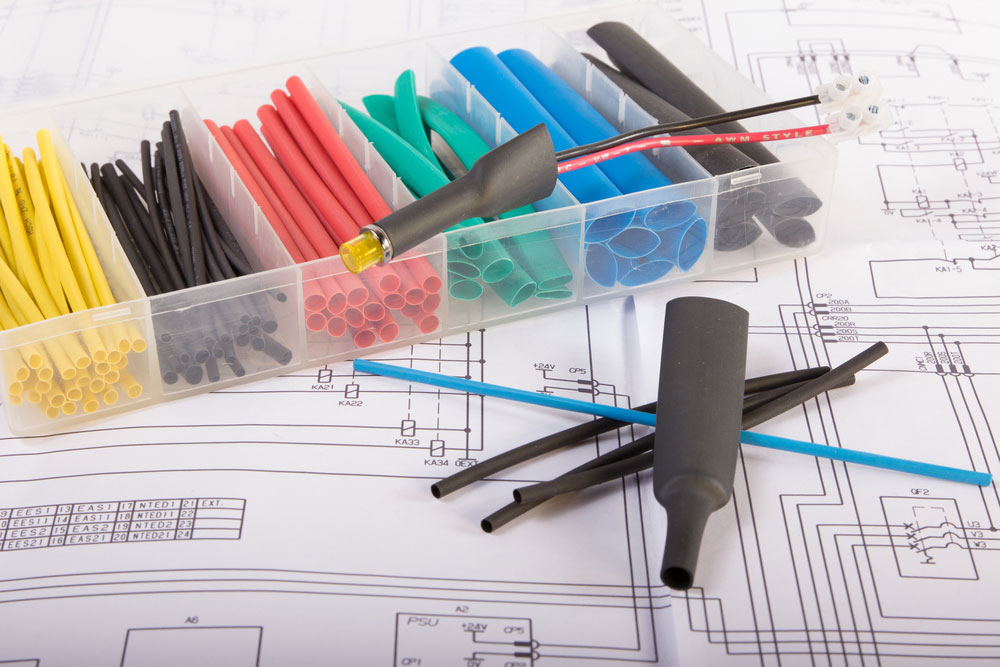

Heat shrink tubing

Caption: Polythene heat shrinking tube

In heat shrink tubing, you will encase the wires or cables through heating. Hence, you will take a blowtorch or hot gun to heat the plastic casing to make it a close-fitting wire cover. Although you can get shrinking tubes in other materials, they are mostly polyolefin.

Polyolefin is flexible, durable, UV and chemical-resistant, and has excellent electrical conduction. Also, the polyolefin is available in multiple colors to color code the wire and organize them properly. Moreover, you can get “clear tubing” as well.

Additionally, the heat shrink tubing has one edge over cable sleeves: “strain relief.” The wires might become useless with cable sleeves since you would have stuffed them into tight spaces. However, as you use the heat shrink tubing, it lessens the strain and keeps the performance of the wire smooth as ever.

Wiring Harness Cover: Fiberglass sleeving Cable wrap

Caption: spiral wire wrap

Cable wrap, also known as spiral wire wrap, protects cables and hoses at a low cost. It is crush-resistant, flexible, and simple to put together. Also, you can branch off the line at any point along with the spiral wrap, making it a practical cable management option.

Moreover, heat-stabilized nylon and polyethylene are the two most popular materials. Heat-stabilized nylon contains a stabilizer that reduces the loss of physical qualities as the temperature rises. Thus, it makes the material’s cable wrap a heat-resistant cable sleeve.

Polyethylene is a long-lasting plastic spiral wrap material. Hence, it can be bent and flexed several times without losing its strength or integrity. Cable spiral wrap isn’t simply for industrial purposes; you may also use it for personal connection.

If you choose to hook or loop braided cable wrap, you can choose between polyester and nylon. For usage, connect the cable fasteners on the ends of the wire and wrap them on the cable assembly. Also, you can reuse them to save the buying cost.

Wiring Harness Cover: Fiberglass sleeving Cable conduit

Caption: cable conduit

Conduit in buildings, industrial structures, and equipment protects and routes cables. Moreover, it has the advantage of ensuring safety when you change the wiring often. Metal conduits can also offer you grounding and bonding. However, a metal conduit is crucial for reducing electromagnetic interference. Hence, they can keep the electrical lines in houses from leaking.

A plastic conduit is also available. These cable conduits are flexible and have a long fatigue life. Plastics’ high impact strength allows them to bounce back quickly after being crushed, making them suitable for outdoor use.

Wiring Harness Cover: Fiberglass sleeving

Caption: Fiberglass sleeving in White

Fiberglass sleeving comprises braided sleeves that are composed of glass fibers. The sleeve has better voltage resistance. Also, it has a temperature tolerance of 200°C, which is extraordinary. Fiberglass sleeves are excellent for generators and motor accessories.

Conclusion

Cable wraps are essential for the smooth working of wires in a system. In automobiles, you need these coverings to make the structure’s functioning smooth. With its help, you can protect the cables from fire and abrasions. Here at Bloom, we offer a wiring harness, and your connection is made with attention to detail.