Wires are everywhere. Everything needs cables to run from the electric appliances you use to the internet connection. Even if you hear about a thing being “wireless,” it still utilizes the wires somewhere in the system. Hence, it would help if you designed the wiring harness types accordingly.

Wire harnesses or cable assemblies are a set of multiple cables that are bound with each other. It keeps the electrical systems organized so that the transmission of signals or power remains undisturbed.

However, you cannot use the same components for every design you create. Still, essential components of assembly have to be used. These three fundamental components are wires, connectors, and terminals. It is the backbone of a wire harness; no system can work without them. Thus, you cannot skip any of these electronic components. Instead, you have to choose from the multiple options available for each of them.

Table of Contents

- Common Types of Wire Harness

- Wire Harness Connectors

- Wire Harness Terminals

- Wire Harness Cables

- Conclusion

Common Types of Wire Harness

As said above, wire harness has applications in nearly every field. Be it household, industrial or commercial level; you need wire harnessing for the power supply. Moreover, you might apply them anywhere, from outdoors with harsh climates to indoors with controlled temperatures, even at sea levels.

Choosing a good wire harness is essential since it will, later on, affect the overall reliability and performance of the system. Hence, the application is critical to manufacturing. Let’s see which industries require wire harnessing for functioning correctly.

Automotive wiring harness

If you have driven any automobile, you know that the first step is to start a modern vehicle. Moreover, the electric power cannot turn the engine on without passing signals and achieving ignition. Hence, to create an automobile, be it a truck, motorcycle, or car, you need a variety of controls for transmitting the signals.

In reality, a complex harness supports the whole process narrated above. Also, the automotive wiring harness is essential for connecting the lighting, power brake, and other automobile components. Thus, there are dozens of electric units of durable in the system and wires stretching inside them over miles.

Manufacturing wiring harness

You need to use complex wiring systems and networks to support the process in the manufacturing industry. The product’s difficulty in manufacturing is; the more complicated the assembly lines found at the manufacturing plant.

Here, wire harnessing connects power and signal transmitters to control different systems in the production line. Moreover, a sound system ensures that the connection is fully optimized, and there will be minimal chances of an issue in production.

Caption: Wire harness close-up in a manufacturing plant

Medical wiring harness

In the medical world, there is plenty of electronic equipment for the scanning and diagnosis of patients. It means that there is also a broad application of wire harness elements, which are durable. Whether it is a drill, pacemaker, imaging, or Radio equipment, it has to work perfectly every time since many lives are at stake.

Because electronic devices in the medical field are vast, you will need to harness components in various shapes and sizes. Also, the need to be bio-sensitive and comply with the FDA controls and guidelines.

Communication wiring harness

Global connectivity is essential. Nowadays, the world has become a global village. Thus, it would help if you relied on specialized wire harnessing to connect everyone successfully in this infrastructure.

Wire harness plays a vital role in assembling communication devices such as hubs, routers, repeaters, broadband networks, and much more. Moreover, wireless communication is incomplete without DSL connectors, and satellite receivers’ wire harnessing.

Military wiring harness

Cabling is essential in many military types of equipment as well. Moreover, wire harnessing of any military equipment must meet the standards in any country. Hence, it would help design a cable harness to overcome extreme conditions.

Wire Harness Connectors

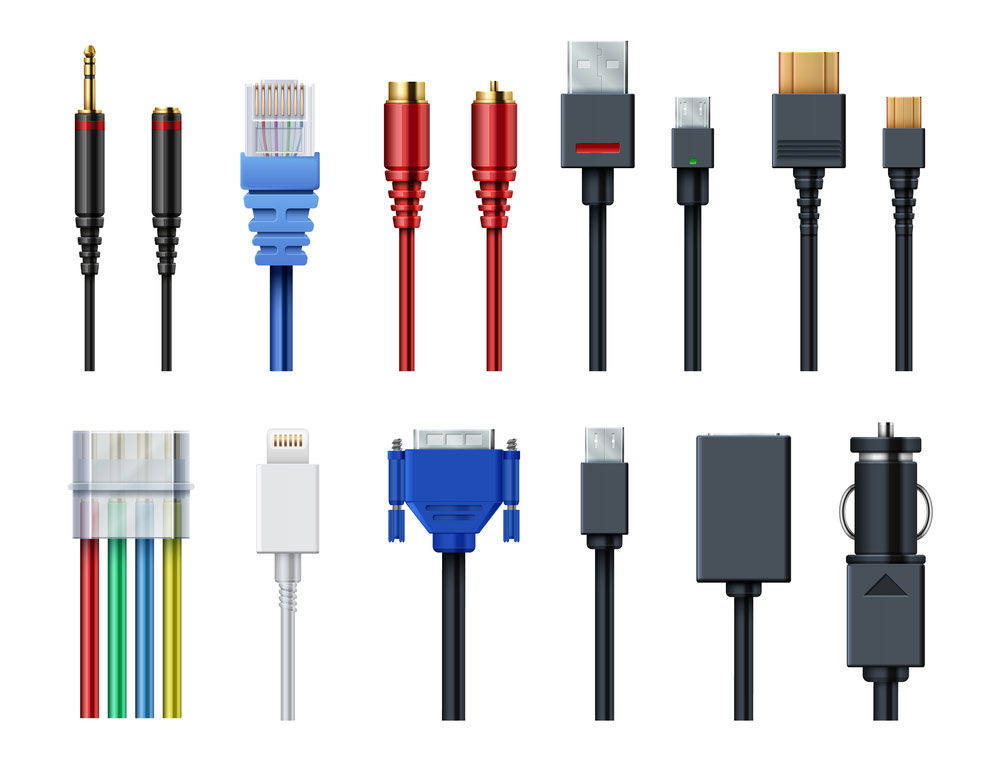

Caption: Types of connectors used in computers

The connector is an electro-mechanical that regulates an electrical connection by forming a pathway to wire from the source. Usually, the connector consists of a male and a female counterpart that bond to make a smooth connection. Thus, you can easily connect or disconnect the pair, and it comes in various shapes and sizes.

Connector Types

The design of a particular connector heavily depends on where you will use it. Hence, you can say that the function dictates the shape. While choosing connectors, you might consider

- How easy is it to mate the connectors?

- What is its mating type?

- Is it durable?

- Is there enough insulation between the two pins?

And so on, depending upon the environment for which you are selecting it.

From consumer electronics to aerospace, military or medical, every field requires a unique type of connector design, and so, you will find a wide range of it.

Choosing the Right Connector

Each connector has several signal contacts, power contacts, and specific configurations such as board to board, wire to wire, and board to the wire. Hence, the manufacturers create a vast catalog of designs, including 2 3, or 4-pin connectors, giving you weather-resistant and locking mechanism options.

Depending on your application area, you can choose whatever suits you best.

Wire Harness Terminals

Caption: Copper electric terminals

You can terminate a conductor to a fixed stud or chassis and establish a connection through a terminal. The terminal is another necessary component in the design of a cable harness. Moreover, it comprises a metal or alloy or other conductive material such as carbon or silicon.

Terminal Types

In a connector housing, the terminals are the familiar pins that secure the connection by providing electronic conduction. The terminals join the connector pins to the associated conductor, whether a PCB board trace or a wire. Just like connectors, the terminals also come in various shapes and sizes.

Terminal types vary as well. Their popular shapes are cable ties, spades, rings, hooks, quick-disconnect, Butt Terminals, and bullets. Thus they can be wire-wrap, soldered, crimped, or press-fit in a ribbon connector.

Choosing the Right Terminal

Again, choosing the right terminal from a wide variety for your connection requires an in-depth analysis of the place you are using it as well as the design you have made.

For example, there are insulated and non-insulated terminals. If you use a terminal in harsh environments, you might require insulation. On the other hand, if the climate is not too critical, non-insulated will work perfectly and be an economically viable option.

Wire Harness Cables

Caption: Bare stranded wires

The most important part of a wire harness is the electrical wires themselves. Therefore, you need to be very careful while choosing the correct cable type. Many cables are used in different conditions, loose wires, stranded, or braided. The important thing is what is the need for time.

Wire Types

Here are some common types of wires

- Flexible Ground Braid, to ground connection between the two terminals, Still it can move or Vibrate.

- Stranded, when you need a flexible wire in a product

- THHN – Solid, where the wiring is fixed, e.g., straight conduits

- THHN – Stranded, where the wiring is flexible, e.g., around the power boxes or within it

- Ribbon Cable – Gray, to make connections in the devices such as DVD players, computers, and hard drives

Choosing the Right Wire

In the older days, the wires possessed potential hazards. To overcome the problem, people came up with insulating the wires with nonconductors or other effective Insulation materials. For example, the Thermoplastic High Heat-resistant Nylon THHN wires are lower in price and provide efficient insulation. To date, it is effective and affordable.

Hence, you need to check out their insulation type to select the wires.

Whether they are PVC coated cables for general purpose use or Polyethene for High-voltage projects, there is a type that can cater to your needs. It would help if you were mindful of your choices in the harnessing process.

Conclusion

To summarize, each harness design is unique and requires selecting specific components to cater to the need. Hence, you need to observe the environment of the application and the constraints applied by the client, and you are ready to select the wire harnessing components.

Here at Bloom, we offer custom wiring assembly and multiple types of connectors, so you’re your connection is made with attention to detail. To avail of our services, contact us now.