A cable harness is essential for any electrical equipment. However, for places where the conditions are intense, you need a military wire harness. The Mil-spec wire harnesses use special connectors, terminals, and wire types that make them immune to wear and tear in harsh conditions and extreme temperatures. Let’s look into the details.

Table of Contents

- What are military wire harnesses?

- Applications of Military Wire Harnesses

- How are Military Wire Harnesses made?

- Automotive Mil-Spec wiring can improve your car’s electrical system but comes at a cost.

- Industry Challenges of Military Wire Harnesses

- Conclusion

What are military wire harnesses?

Military wire harnesses are specially designed and tested for extreme operations. Moreover, they have to meet the MIL-SPECs. Thus, manufacturers must use connectors, wires, terminations, and other elements according to standards.

After manufacture, the military wire harness also undergoes rigid testing with higher temperatures and pressure to qualify for many uses.

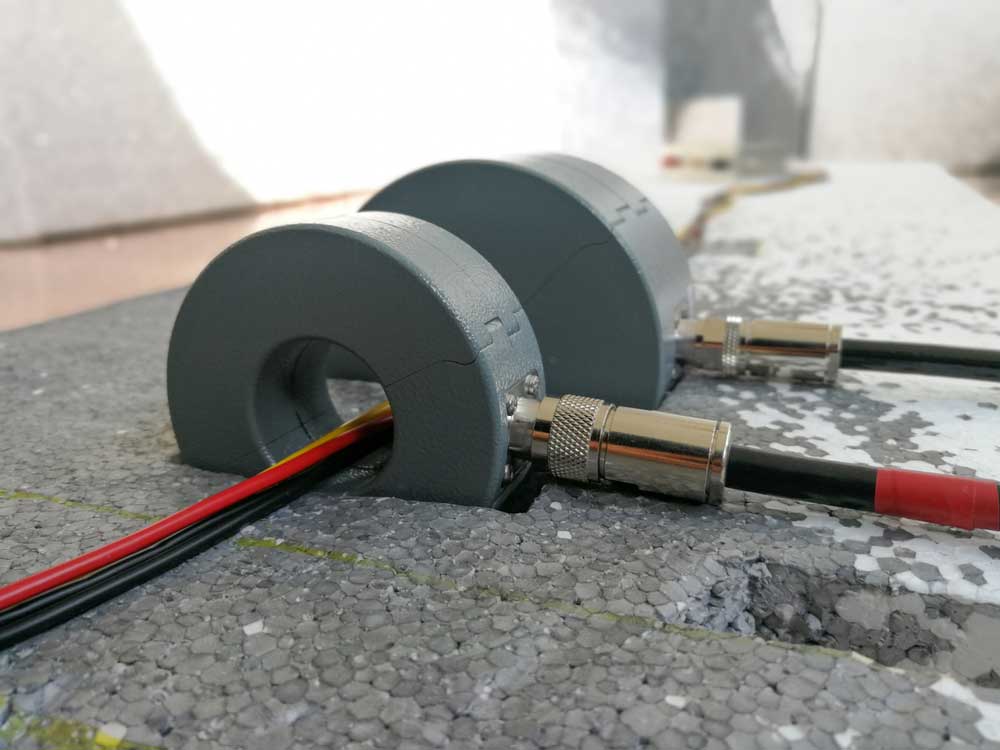

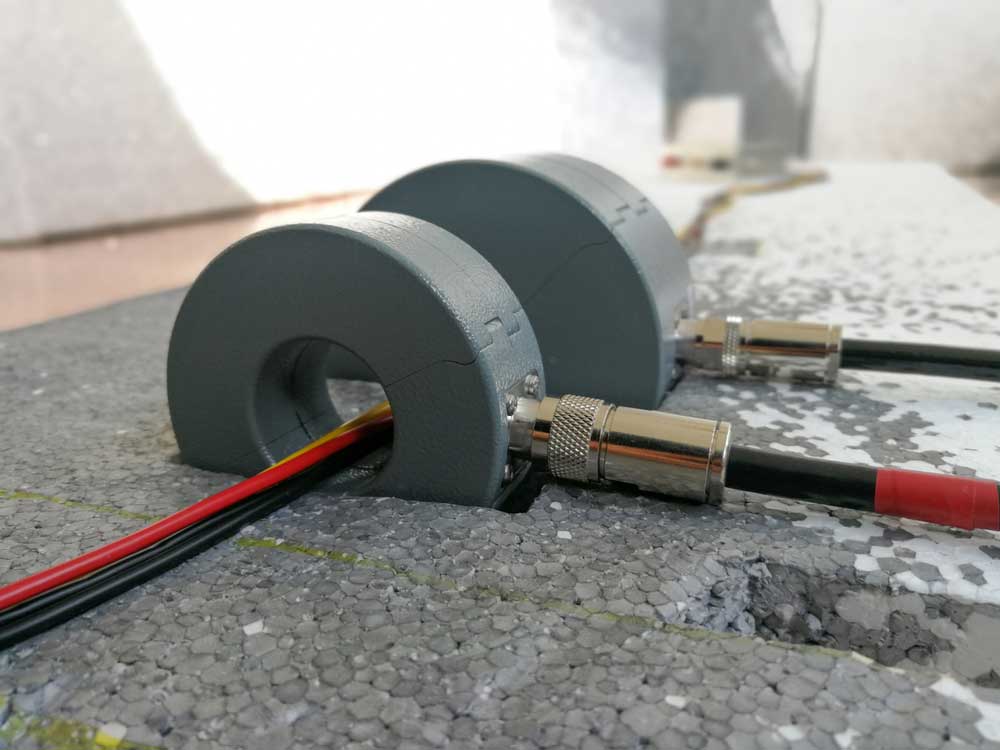

Caption: Military-grade hydraulic system wiring

Applications of Military Wire Harnesses

- Tractors and other ground-based military Equipment

- Equipment for both in-field and in-between-base communications

- Tools for aerial communication and navigation

- Control of Weapons from a Distance

- Marine machinery includes ships and submersibles

- Robotic spacecraft and artificial satellites

- Electromagnetic interference-sensitive avionics

- Weapons of the Space Force

All in all, cable and wire assemblies used in aerospace applications and military systems ensure reliable performance in many crucial contexts.

How are Military Wire Harnesses made?

You may have observed a commonality in the electrical systems of government-owned aircraft, autos, and boats.

First, wires typically have a Teflon coating to resist heat and reduce RF interference.

Also, special features, such as service loops for strain relief and twisting tactics to maintain the wires flexible and bend in any direction, add complexity to the wiring process. To further conceal the cables, manufacturers use high-grade heat-shrinkable tubing.

In addition, the mil-spec bulkhead connection is the most recognizable and readily identifiable part of these vehicles’ wiring harnesses. A bulkhead is useful here because it provides a conduit for the cables to run through. That could be an engine’s airbox, a building’s firewall, or a fender’s well. The circular shape, barrel crimps, and high-quality gold connections of Mil-spec bulkhead plugs guarantee reliable connections. These connectors have a rubber boot that fits with a rubber O-ring and a threaded shell on the rear.

Caption: Bulkhead plugs

Automotive Mil-Spec wiring can improve your car’s electrical system but comes at a cost.

But, Why do military wiring harnesses cost more than another electrical wiring?

- When the room is at a premium or when aesthetics and discretion are priorities, the bulkiness of typical wiring looms might be a problem. Mil-Spec wire is in demand because of the many criteria and requirements it must meet before placing in vehicle construction.

- The military and aviation industries are the inspiration for automotive Mil-Spec wiring due to their strict requirements for quality and safety in their operations. Like high-quality copper, manufacturers make actual military-grade wiring under severe conditions that guarantee durability, dependability, and purity. These regulations and standards aim to make the power grid more reliable and safe.

- Mil-Spec cables are Teflon-coated to block radio frequency transmissions to avoid electrical disturbance.

- Military specifications for wiring also take compactness and lightweight construction into account.

- Mil-Spec crimping calls for a unique tool, distinct from common crimpers, that features a wrench and a detachable turret. The M22520-1-01 Standard Indent Crimp Tool, produced by Daniels Manufacturing Corporation (DMC), is widely recognized as the gold standard crimper in the world. A turret is needed, and it is offered separately from the tool. The DMC M22520-01-02 turret features three holes, each color denoting a different maximum wire size that you can crimp. It’s not your standard wire crimper; it’s more like a surgical tool. This level of complexity is reflected in the higher cost, which can be upwards of $400 for a complete handle and turret assembly.

Due to the high difficulty and time investment required, the cost of creating a wire harness for a specialized vehicle can easily exceed $18,000.

Industry Challenges of Military Wire Harnesses

Cable assembly builders should take a lot into account when designing the military wiring harness for quality products.

Reliability and Quality

Due to the high stakes in military tasks, all systems must function with unprecedented reliability. Therefore, all cable components used in the aviation and army industries must meet strict quality control standards.

Moreover, all electrical components used in aeronautical cable assemblies and military connectors undergo extensive testing. Component testing can involve exposure to high pressures, high temperatures, high voltage, corrosive substances, contact force, vibrations, and many other potentially damaging circumstances. You will choose the parameters and cable solutions based on the application area.

Extreme Environments

Equipment used in the aerospace and military industries must function consistently in some of the harshest conditions on Earth. Military vehicles may be deployed in various environments, from the sweltering desert to the ocean’s depths, where they will face the corrosive effects of salt water, freezing temperatures, and tremendous pressure.

Mil-Spec cable assemblies and wire harnesses can withstand the rigors of these conditions by using materials impervious to severe heat and cold, corrosion, radiation, cuts, and other threats to operational dependability.

Military Wire Harness: Strength and Durability

Cables and wiring harness used in the military and aerospace sectors must be of extraordinarily high strength and durability to meet industry standards. Moreover, they must be able to handle extreme pressures, impacts, wear and tear, and excessive vibration. If a single failure exists, it could have devastating results and risk millions of people’s lives.

Military Wire Harness: Application Complexity

Standard Equipment will typically fail to meet the demands of a military application because of the particular operating conditions specific to the field. For instance, a typical auto wiring harness would die in a military vehicle. To improve performance and award-specific properties, a manufacturer must have in-depth knowledge of all materials, alternatives, and technologies at their disposal.

Some complex settings that could benefit from the usage of wire and cabling solutions are as follows:

- Instrumentation controls for fighter jet cockpits

- Discussing the nuts and bolts of Space Force rocket launches

- Equipment for ground forces, such as night-vision goggles and radios.

Conclusion

Military wire harnesses and aerospace cable assemblies use mil-spec components for their build. However, these components and the maintenance can cost you a lot as it involves using high-grade, specialized Equipment. Moreover, these wire harnesses must comply with the strength, reliability, and extreme condition standards. Here at Cloom, we offer standard wiring harnesses and custom cable assemblies to make your connection safe and reliable.