Best Way To Get Plastic Off Copper Wire, If you want to sell or recycle the copper from inside your wires or need to strip them, you may have trouble working out how to do this. Fortunately, there are some methods to choose from, and this article will describe each of these methods in detail.

It will also explain the best tool to use depending on how many wires you need to separate the plastic from each month.

Table of Contents

- Method 1: Fire burning

- Method 2: Stripping the Wire with a Knife

- Method 3: Stripping the Wire by Boiling

- Method 4: Removing Corrosion

- Method 5: Wet copper wire recycling machine

- Method 6: Dry-type copper wire granulator machine

- For the number of wires, what tool should I use?

- Conclusion

Method 1: Fire burning

Plastic is a material that melts quite easily, while copper only melts at extremely high temperatures. Burning a wire can remove the plastic casing entirely while keeping the copper. One of the biggest problems and inefficiencies with this method is the amount of material loss. It’s a cheap method, not an efficient method. And there is a huge amount of pollution created with this method.

Pollution created by the fire burning

Method 2: Stripping the Wire with a Knife

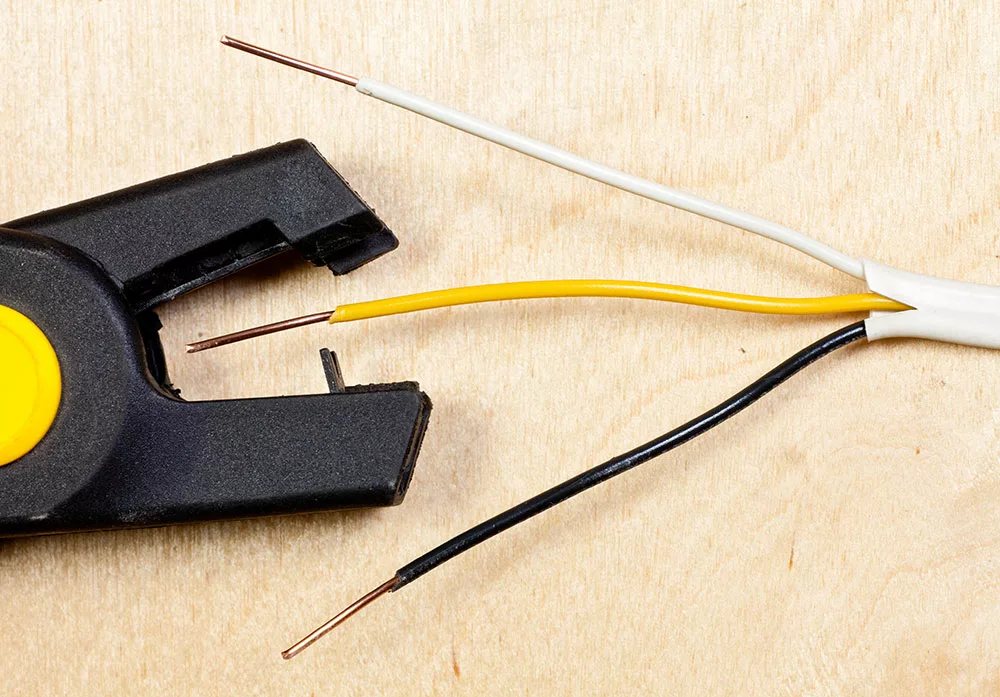

- Firstly, use a razor blade or a small pocket knife to cut a small slit into the wire’s plastic casing. You could also use a wire stripper to do this. When doing this, use gloves to prevent the risk of cuts, and don’t cut through the wire itself – just the plastic casing.

Pocket knife for cutting plastic casing

- Next, remove the plastic casing from the wire by slowly sliding it off. It could take some time, but with persistence, you’ll get there eventually.

- If there are any plastic remnants on the cable, you could try one of the other methods to make sure they are completely separate.

Method 3: Stripping the Wire by Boiling

- Start by using a kettle to boil the water so that it’s boiling (100 degrees Celsius).

- Place your wires inside the pot of boiling water and leave them there for around 10 minutes. Be careful not to burn yourself – always use gloves and watch for spitting water.

- Once the wire has been boiling for around 10 minutes, remove it with tongs or a similar utensil.

A pot of boiling water

- While wearing gloves, pull the plastic casing off the wire straight away. Don’t allow the wires to cool before beginning this step.

Method 4: Removing Corrosion

- First, add 1 tablespoon of salt and 1 cup of vinegar to a medium-sized bowl. Mix the two ingredients using a spoon or whisk.

One tablespoon of salt

- Secondly, place your wire in the mixture and allow it to sit there for a while. Depending on how much corrosion is inside the plastic casing, you may only need to leave it in the bowl for 10 minutes or as long as an hour.

- Once ready to remove the wire, clean any debris using a brush, sponge, or cloth. Then, take it out of the mixture and rinse it off using the solution from the bowl.

- Using clean water, rinse off the wire and then let it dry.

Method 5: Wet copper wire recycling machine

A wet copper wire recycling machine is specifically to separate plastic casings from the wires. They use water as their main method of separating the casing from the wire. Firstly, the machine crushes the wire into particles, and gravity naturally separates copper from the plastic. The copper then goes through water processing, which cleans the copper.

Method 6: Dry-type copper wire granulator machine

Dry-type copper wire granulator machines are similar to their wet counterparts but don’t use water to get the job done. Instead, they use shredding, crushing, air separation, and electrostatic processes. The machine cruses wires to separate copper and plastic through gravity. Then, electrostatic machines pick up the copper to maximize the separation. This method is much more effective than wet separation.

For the number of wires, what tool should I use?

For small quantities of wires (up to 50kg or 110lbs per month), a razorblade or wire stripper is the best tool to be using. They’re cheap and easy to use, so you won’t have to spend large operating expenses or waste time setting up the tool. Conversely, it is very labor-intensive, so if you are not particularly strong, you may have trouble using these tools for extended periods.

Manual wire strippers

If you’re stripping between 50 kg (110 lbs) and 250 kg (550 lbs) per month, a slightly more complex piece of equipment is probably a good investment. It could be something as simple as electric wire strippers, which take the labor out of the standard wire stripping processes. It could also be something like the facilities to operate fire burning, which is a bit more expensive but could be worth it in the long run.

Finally, for more than 250 kg (550 lbs) per month of separating plastic casings from the wire, investing in a wet copper recycling machine or a dry-type copper wire granulator machine is almost certainly worth it. You’ll have almost no labor involved in the process and a highly scalable system that will work for as many wires as you may need to strip. While they are more expensive, they are usually a good investment for such large quantities of wires.

Conclusion

Separating the plastic casing from the copper of a wire is not as difficult as it sounds. This article covered six methods for achieving this:

- Fire burning – melts the plastic off the copper.

- Stripping with a Knife – using a knife or razor blade, cut the casing away from the wire.

- Boiling – heat the wire so the plastic slides off easily.

- Remove corrosion – clean the wire, so the plastic has less friction when sliding off.

- Wet recycling machine – uses water to separate copper and plastic.

- Dry-type separation – uses electrostatic machines to separate copper from plastic.