Horn is the most familiar component in a vehicle since everyone uses it for safety. Its primary purpose is to warn other drivers of its presence so that the accident chances are less. Mostly, you will find the horn button on the steering wheel that will activate the horn under the hood. However, what if it turns faulty? The answer lies behind the horn relay wiring.

Table of Contents

- How your horn works

- Common Automotive Horns

- Horn Wiring Examples

- Reasons your horn isn’t working

- Conclusion

How your horn works

The horns make a sound when a car moves metal diaphragms.

It uses an electromagnet or solenoid and a thin metal disc to generate electrical sound. When you push the button, electricity flows through the solenoid, which then applies pressure to the metal disc.

To ensure a horn is in working order, connect it from the battery to the jumper wire, then to the hot terminal. Moreover, you must connect it to the ground when it stops working correctly. Once it’s up and running, you can figure out where the ground connection went wrong. Cadmium-plated screws are a common fix to avoid breakdowns.

Caption: car horn

Common Automotive Horns

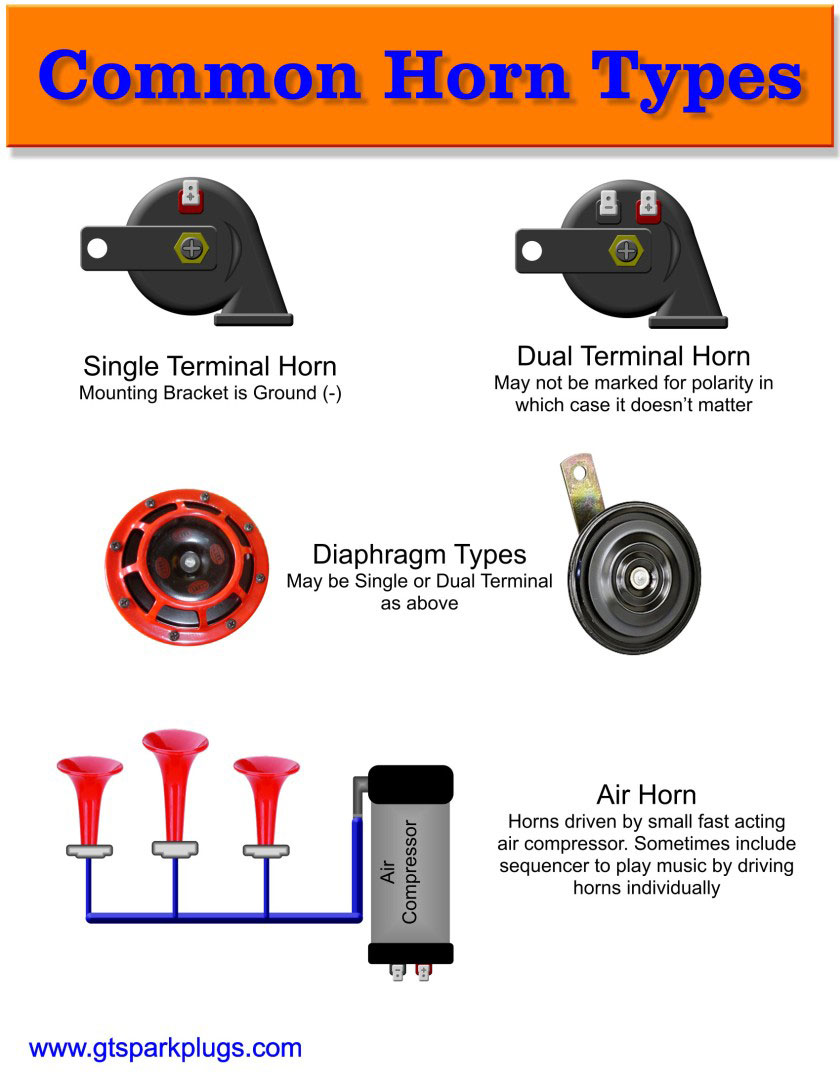

Horns for automobiles, motorcycles, and boats generally have a familiar appearance. However, some original equipment manufacturer horns may look slightly different.

- If your horn only has a single terminal, the mounting bracket can serve as the Ground connection. Therefore, the Positive lead from the single-terminal horn will connect to the connection, and the chassis ground wire will complete the horn relay wiring harness.

- If your horn has two prongs, you may wonder which one is “+” and which is “-.” The red and black (+) and “-” markings on some devices indicate the correct polarity for connecting the two. You can combine them in either direction if there are no markers for both horn-shaped (top row) and diaphragm-shaped (middle row) horns.

Caption: common horn types

Source: http://www.gtsparkplugs.com/horn-wiring.html

Horn Wiring Examples

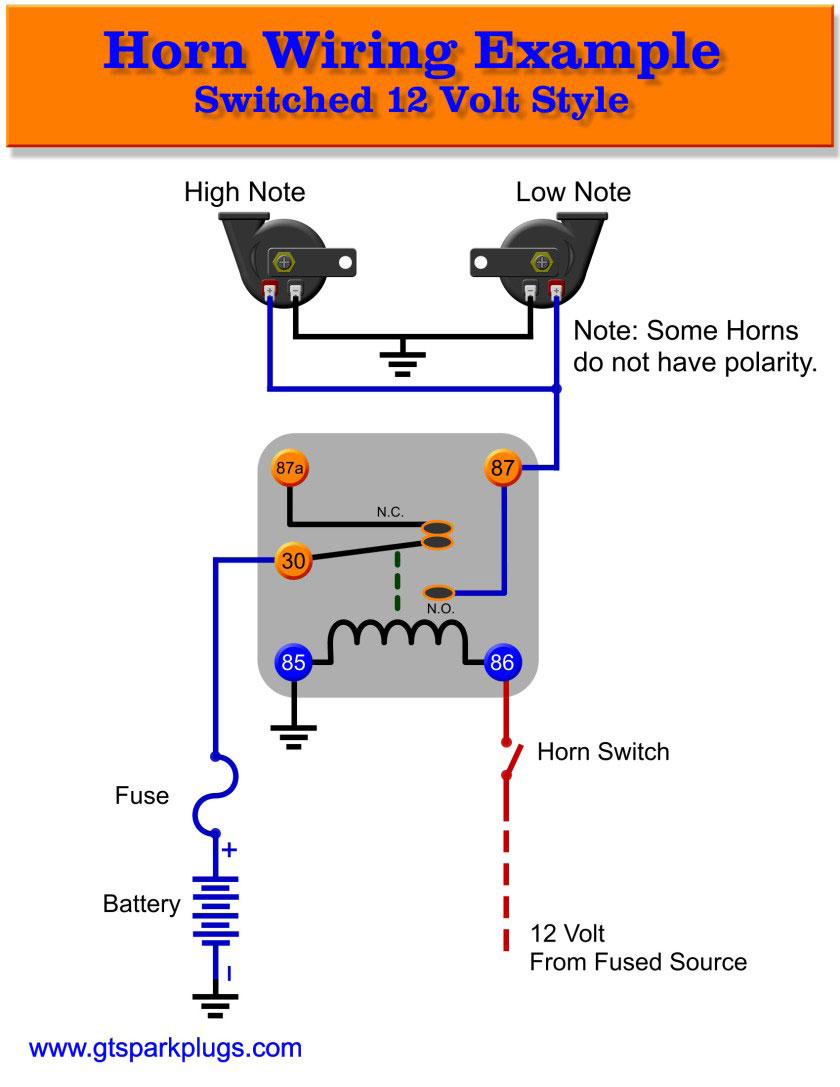

There could be two wires leading to the switch on some vehicles. Or maybe you just opted to wire anything with a toggle switch this way. In any event, it’s the kind of standard wiring that the rest of your devices might employ. Newer cars probably use this system. Moreover, the 12 Volt side is switched differently. Thus a horn switch would require 12 Volts to be fed to it and then passed back to the relay.

Horn wiring typically varies slightly between relay designs.

First Know The Basic Relay System

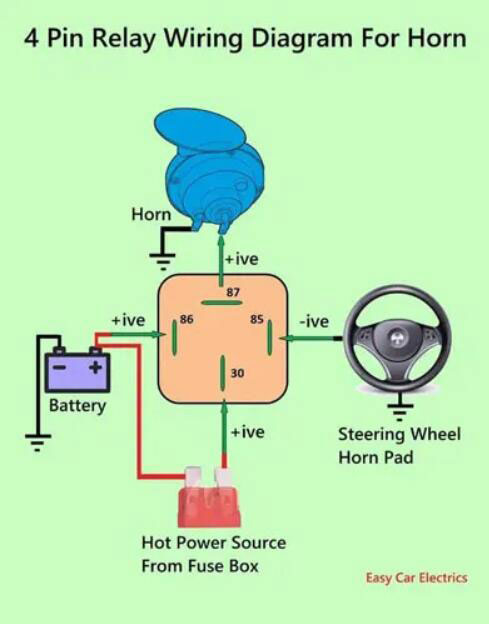

If you have the relay’s schematics, setting it up is simple. Standard relay terminals have numbers 85, 86, 30, and 87. Also, two different circuits, a high ampere circuit, and a coil circuit make up an automobile relay.

Terminal 85 is the negative end of the coil loop and receives the ground power source. In contrast, terminal 86 is the positive end and gets the hot source of power. And when you turn on the coil circuit, it produces a clicking noise.

In addition, terminal 30 transmits twelve-volt power from the battery to terminal 87 in a high amperage circuit.

The five-pin relay has a fifth terminal, 87a, which is usually closed. And by energizing the relay, the power is cut off.

Caption: 4-Pin-Relay-Wiring-Diagram vs. 5-Pin-Relay-Wiring-Diagram

Source: https://www.easycarelectrics.com/

Caption: working principle of 4-pin and 5-pin relays

Source: https://www.easycarelectrics.com/

4-pin relay wiring diagram for horn

When the horn pad on the steering wheel is depressed, the relay is activated. The battery’s positive terminal is connected to the coil circuit’s contact 86 via a relay.

The coil circuit of the relay is ignited whenever terminal 85 of the steering wheel horn pad is depressed. This coil circuit sends power from the fusebox’s terminal 30 to the car horns. The car’s relays for the horn are connected in this configuration.

Caption: 4-pin relay wiring diagram for horn

Source: https://www.easycarelectrics.com/

5-pin relay wiring diagram for horn

Like 4-pin relays, the switch is powered by a 12-volt coil that links to pins 85 and 86. However, connecting pin 30 and 87a is done while the 12v coil is not receiving power.

Caption: 5-pin dual horn relay wiring

Source: http://indoxxie.com/

Horn Switch Grounding Relay Wiring

The horn switch completes the circuit to the ground in the example above. It is a typical steering wheel wiring diagram. The switch grounds the horn button’s wire to close the circuit. Not usually, but often. How big is the fuse or wire? Start with a fuse rated for your horn(s) of current size or bigger. Then use the wire size calculator for horn wiring. If you’re wiring an air horn, the positive wire will emerge from terminal 87, and the ground line will tie to a chassis bolt.

Caption: grounding switch style

Source: http://www.gtsparkplugs.com/

Reasons your horn isn’t working

Inspecting the horn wire is possible to determine the source of issues.

Fuse issues

Since the horn uses electricity to work, it consists of a fuse like other electric systems. If the fuse blows, you must replace it with a new one. Moreover, modern cars use a fuse like a fork; as you have seen the broken cables, you have to take action on it. Just replace the fuse with a colored wire to get back to honking again.

Relay issues

If the problem is not with the fuse, it may be the faulty relay. However, you might not inspect the relay problem with the naked eye. You can swap it with another one to check if your relay is not working. If that’s the case, buy the new one and replace it. Otherwise, check if there are other underlying issues.

Horn unit issues

If both fuse and relay are not problematic, there is a chance that the problem is with the horn unit. You must give it some current via jumper cables to verify it. Moreover, disconnect them immediately while touching the horn with the jumper wire to prevent loud honking.

Horn switch issues

The horn switch is usually in the location where you press the horn. Primarily, it resides in the steering wheel, so you must go to a mechanic if it breaks. It’s not necessary to know the mechanic of a steering wheel, airbag, and wiring inside. However, if it’s the horn switch, don’t touch it.

Clock spring issues

A broken clock spring could be to blame if you went to activate the horn but heard nothing when you pressed the button. Furthermore, you can try turning the wheel while pressing the horn button; if you hear a sporadic sound, you must replace the clock spring.

Wiring issues

Sometimes, it’s only the broken wires or connectors. For that, you can only unplug and plug the connector again. It will solve the issue.

Caption: steering wheel repair disconnecting horn circuit

Conclusion

When used, the horn makes a clear and loud ringing sound that can effectively warn other motorists. In most cases, the signs of a malfunctioning horn will present to the driver. A vehicle with a broken horn is not up to safety requirements, as stated by federal laws, and may be subject to a ticket. Hence, to rewire it, you need specific guidelines that you will get in this article. Here at Cloom, we offer wiring harnesses and cable assemblies to make your connection safe and reliable.