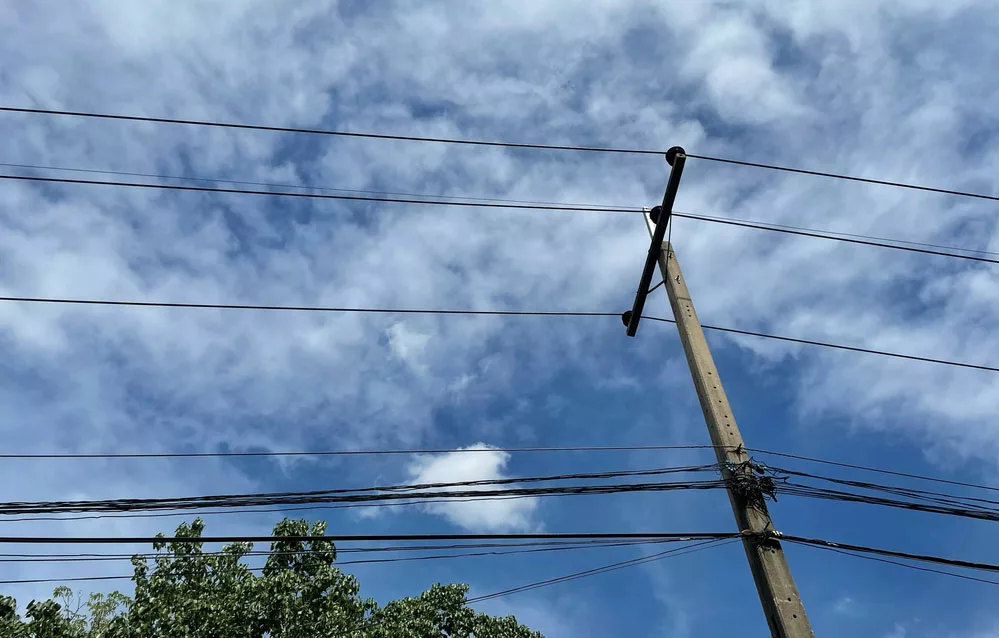

Overhead electric wires are crucial to modern power transmission and distribution infrastructure.

Unlike underground power cables, they run above the ground at an appreciable height.

To keep it simple, overhead electric wires are basically wires strung on utility poles that transmit electricity or data from one point to another.

This article expounds on why we use overhead cables, the best materials for overhead wires, and compares the two main cabling constructions.

Table of Contents

- Why Are Electric Wires Installed Overhead?

- What Type of Wires Does Overhead Cable Construction Use?

- Overhead Vs. Underground Wiring Systems

- Which Is the Better Power Cable, Aluminum or Copper?

- Are Overhead Cables Dangerous?

- Can I Run Electricity to My Shed Overhead?

- Summary

Why Are Electric Wires Installed Overhead?

Overhead cables are not a rare sight. But what makes you opt for a more aerial solution to cabling?

Accessibility for Maintenance and Repair

Overhead cables are more accessible than buried cables, making maintenance and repairs easier. If there is an electrical fault, you can easily identify and fix it.

Nature of Transport Infrastructure

Overhead Line Equipment (OLE) supports and manages the overhead cables in electrified railway and tramway systems. This kind of system requires overhead cables to operate optimally.

Note: Overhead cables in railway stations should have appropriate insulation equipment to ensure the safety of all rail users.

What Type of Wires Does Overhead Cable Construction Use?

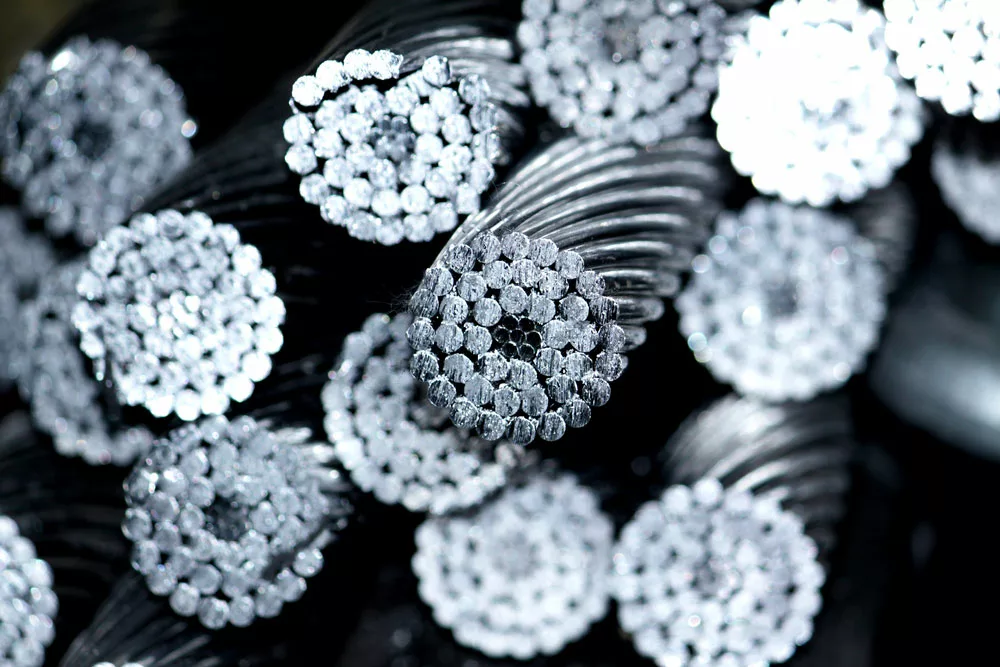

Cross-section of a power cable

Copper and aluminum are the two most popular wire types for cabling. To facilitate the smooth flow of electricity, power cable wires must have good conductivity.

When selecting a wire type for cabling, it is essential to consider various parameters.

- The electrical conductivity of the wire.

- The cable’s tensile strength.

- The density of the wires.

Aluminum is and has been for years the superior and popular option when it comes to overhead cabling.

In some cases, overhead cables may also include additional components such as lightning arrestors, spacers, and dampers to protect the system.

Overhead Vs. Underground Wiring Systems

Exposed underground cables

These polar opposite cabling methods have their pros and cons depending on their intended use. Some of the factors that set them apart include:

Cost

Overhead cables are relatively cheaper than underground wires. When installing, repairing, or upgrading, they generally incur lower costs. Underground cable construction involves digging trenches, which is an added expense.

It is also very expensive to purchase specialized tools for installing underground wiring systems.

Installation time

Installing underground cables is more time-consuming than setting up overhead cables.

The process involves digging trenches for laying insulated cables and restoring the surface. Installing overhead cables does not require excavation.

Versatility

Overhead power cables are the go-to for power distribution in remote areas where digging trenches is not feasible, like rocky environments.

This makes them a versatile option for providing electricity to homes and businesses in areas where other options are limited.

Weather Conditions

Piled coiled wires

Weather plays are crucial role in the longevity of the cables. Overhead cables in windy and stormy areas are more susceptible to damage than underground wires. Flood conditions can easily damage underground cables.

You should therefore factor in the most recurrent weather in your area before choosing to go overhead or underground.

Troubleshooting

It is easier to spot faults and problem points in overhead cables than in underground cables. This is because overhead electric cables are more visible and easily accessible, making troubleshooting straightforward.

Insulation

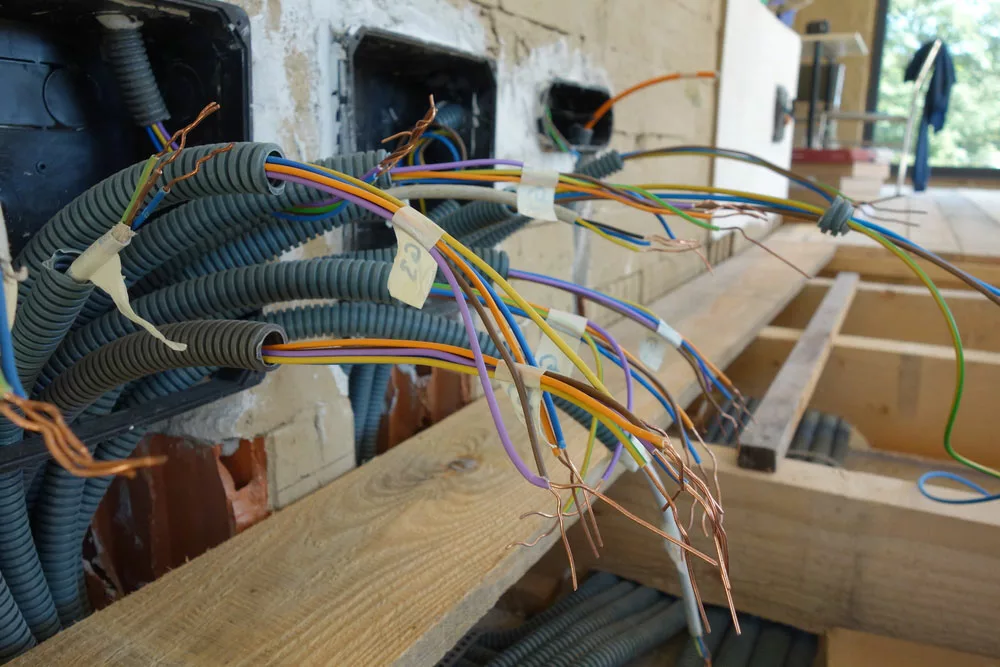

Electric cables with insulation during installation

Overhead cables are generally more exposed to external factors such as weather and wildlife, which can increase the risk of damage or faults.

They have bare conductors strung on poles or towers using materials such as porcelain or polymer for insulation and mechanical support.

Underground cables use protective enclosures to bury the conductors. The conductors use insulations of materials like cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR).

These materials protect against moisture, abrasion, and other external factors that could cause faults or damage.

Which Is the Better Power Cable, Aluminum or Copper?

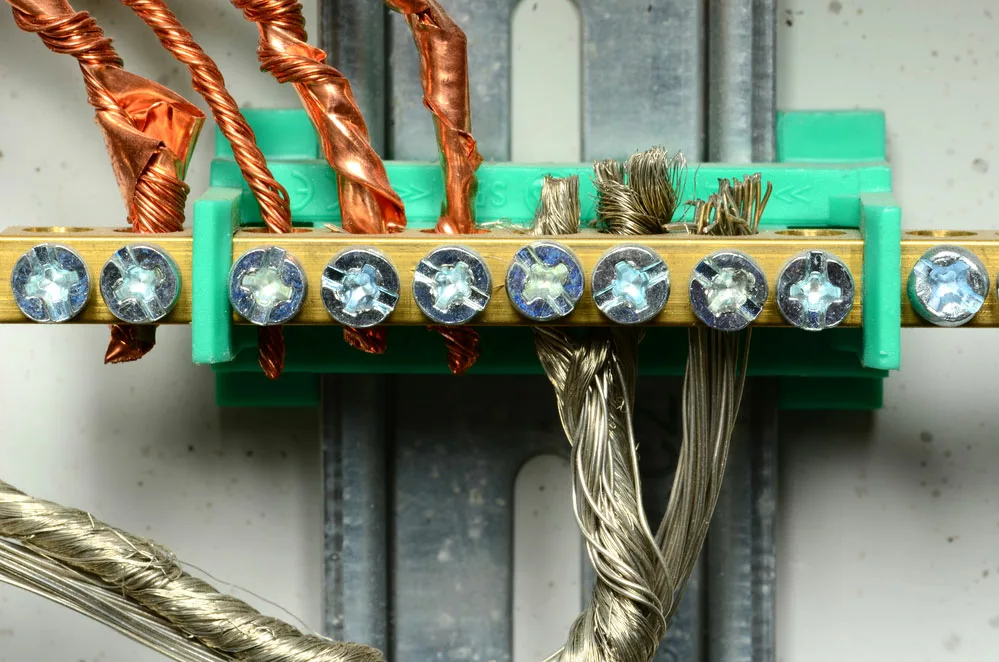

Copper and Aluminum wires are connected to a distribution board.

Aluminum is 30% lighter than copper. Copper, however, is about 40% more conductive than aluminum. Considering the two conditions, aluminum with half copper’s weight has the same conductivity.

Aluminum is also a more readily available metal when compared to copper. Due to its scarcity, copper is often priced higher than aluminum. The two elements undoubtedly have their strengths, proving to be up to the cabling task.

Nevertheless, aluminum is a more feasible choice for overhead electric cable installation.

Are Overhead Cables Dangerous?

Tangled cable wires on a pole

Yes. If the cables are poorly installed, serious damages are a huge possibility. Activities that involve some form of elevation of humans or equipment are also prone to impending danger when contact with the electric cables is involved.

Can I Run Electricity to My Shed Overhead?

Electrician cutting a cable using a pair of wire cutters

Absolutely. To supply electricity from your main panel to your shed by overhead means, you should have some of these considerations in mind:

- Your locality’s laws and regulations.

- The equipment and parts to be bought include guy wires and clamps.

- Clearance around the wiring’s surroundings.

Installing an overhead service drop is one way to run electricity to a shed overhead. This method requires the installation of a utility pole and appropriate support structures, as well as the proper electrical wiring and equipment.

Before installing, it is important to consult with a licensed electrician to ensure all safety codes and regulations are in check.

Additionally, obtaining any necessary permits and approvals from local authorities is important before starting any work.

Summary

Overhead electric cables are vital in providing electricity to homes and businesses worldwide. Its applications depend on several reasons, such as cost, nature of residence, and terrain.

You should always contact experts for guidance when choosing the type of cable to implement. Be sure to observe the general electrical and building codes and necessary precautions because safety matters.