There are many types of coaxial cable. So how do you choose the best type to use in your project?

Electrical performance should be your first consideration. You then need to think about mechanical issues including strength and flexibility.

In this article, we introduce different types of coaxial cables classified by their impedance, construction, and conductor thickness.

Table of Contents

- Why are there different types of coaxial cable?

- Different impedances of coaxial cable

- Different constructions of coaxial cables

- Different sizes of coaxial cables

- Conclusion

Why are there different types of coaxial cable?

A coaxial cable’s prime purpose is the transmission of a high-frequency electrical signal between two points. The type of cable depends on the application.

Indoor applications often need flexible coaxial cable runs of only a few feet. Whereas outdoor applications need a rigid cable with cable runs measured in hundreds of feet.

It is important to maintain the quality of the electrical signal during transmission. This means losses should be low and electrical interference minimized. Also, the electrical characteristics of the cable must match those of the end equipment. These factors all have a bearing on the type of cable you should choose.

Different impedances of coaxial cable

A coaxial cable is a transmission line, and they have electrical properties, including resistance, inductance, capacitance, and leakage. The combination of these properties is the transmission line’s characteristic impedance (Zo), measured in Ohms.

The Zo of the transmission line should match the input impedance of the equipment. If not, some of the signals will bounce back (reflections). This reflection will affect the electrical performance of the cable. You will notice some coaxial cables have a 50 Ohm specification and some 75 Ohm.

The Ohm is the unit of characteristic impedance. Hence, coaxial cables of 50 Ohm work well in 50 Ohm input impedance applications. These include radio transmitters and Ethernet networks. You will find coaxial cable 75 Ohm in TV, audio, and video applications in the home. Besides, you will also find them in some telecom systems.

Different constructions of coaxial cables

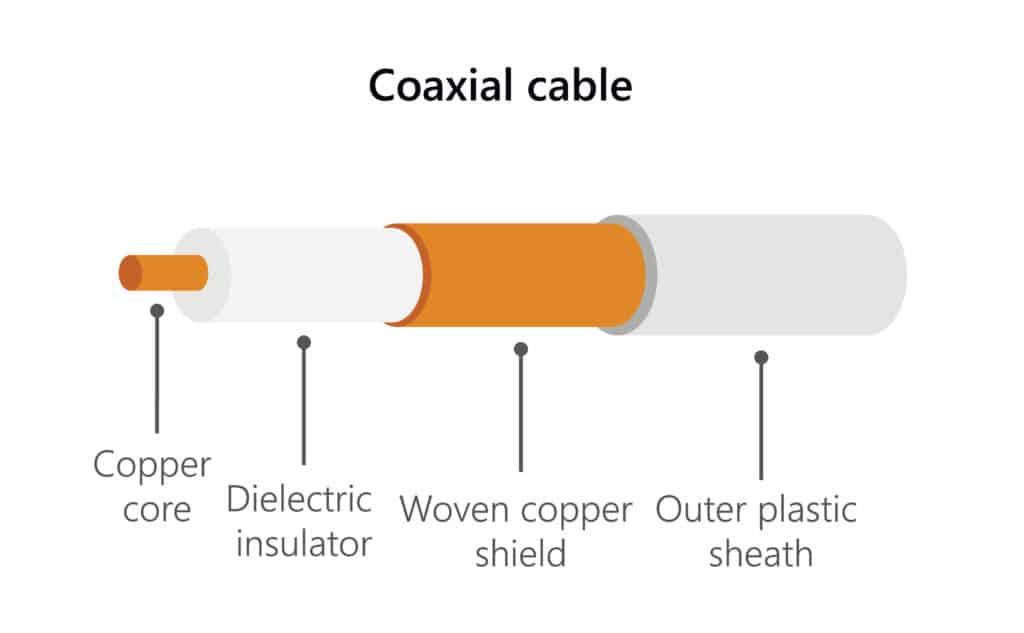

A transmission line consists of two conductors separated by a dielectric. In a coaxial cable, these are the central conductor and the metal sheath.

The most common types of coaxial cable use a single central conductor separated from the metal sheath by a dielectric material. A protective insulating layer completes the assembly.

Depending on the application, there can be multiple conductors. The metal sheath can be solid or woven metal material and the outer insulating coating can be flexible or rigid.

Flexible coaxial cables

Generally, you will find flexible types of coaxial cable in the home in TV aerials. The central conductor is usually solid but the sheath is woven metal and the outer coating is pliable to maximize flexibility.

Semi-rigid coaxial cables

These are similar to the flexible cables described above. What makes them different is that solid metal replaces the woven metal sheath. And the most common applications for these cables are microwave equipment.

Formable coaxial cables

As formable cables, they are an alternative to semi-rigid cables. They replace the solid metal sheath with a flexible version. So the cable is easier to install.

Hard line coaxial cable

The main application for Hard-Line coaxial cables is outdoor cable runs of over 400 feet. With high strength and endurance, these cables are thicker than most other types of coaxial cable.

Twin axial cable

Instead of one central conductor, twin axial cables have two. The rest of the cable construction is the same as the flexible types of coaxial cable described above.

Triaxial cable

Triaxial cables use an extra copper braid, connected to the ground, to block external interference. Compared to single-core cables they deliver a higher level of shielding and lower losses.

Rigid Coaxial Cable

The primary use for rigid coaxial cable is high power TV and broadcasting applications. Another common application is Antenna masts. They use a central insulated conductor inside a metal tube. Insulating beads placed at regular intervals insulate the central conductor from the metal tube. The rigid tube structure means these cables do not bend.

Different sizes of coaxial cables

You will find coaxial cables classified by their impedance and the conductor thickness (gauge). The standard measure of conductor thickness is the Radio Guide Number (RGA). The higher the RGA number, the thinner the conductor.

All cable sizes described below are 75 Ohm impedance.

RG6

You are most likely to find RG6 coaxial cable in domestic settings. The thick insulation, flexibility, and high-quality shielding make it ideal for TV and internet applications.

RG11

A thicker conductor makes RG11 rigid and difficult to use in indoor applications. Instead, it is often used outdoors in long cable runs.

RG59

You will often find RG59 in similar applications to RG6. Its thinner conductor makes it more flexible but its overall performance is lower.

Conclusion

Many electrical and mechanical factors influence your choice of coaxial cable including electromagnetic interference, impedance matching, and installation issues. Sometimes the ideal cable type will not be available and you will need to compromise.