In most cases, you have seen the implementation of electromechanical components in electrical systems. As you work with them, you will need an enclosure or panel where you can keep the components secure and functional. Box build serves the purpose of integrating the system inside a box. This article will look into the box build and the factors that make the implementation successful

Table of Contents

- What is Box Build?

- The application of box build assemblies

- Sub Assembly Components for Box-Builds

- Box-Build Designing Goals

- Box-Build Manufacturing Process

- Things to Consider for Box Build Assembly Process

- What Are the Most Common Issues with Box Build Assemblies?

- Benefits of Good Box Build Assembly Services

- Conclusion

What is Box Build?

Box-builds are the system integration that focuses on assembling a complete finish product. It works beyond PCBs that include wiring, fabrication, and installation of cables and subassemblies. In short, box building is a process where you assemble electromagnetic components. The services include

- Sub-level product assembly

- Designing and implementing all the components (like die casting, injection modeling, etc., etc.)

- Fabricating enclosures

- Setting up sub-assemblies and individual components.

- Wire and Cable harness routing

- System-Level Assembling

- Product and Software Configuration

- Functional Testing

- Complete system testing and Burn-In

- Custom testing systems with integrated software and hardware solutions

- Labeling and packaging

- Keeping it in a warehouse, order placing, and tracking the order

- Custom tool providing

- Build-to-order and configure-to-order (BTO & CTO)

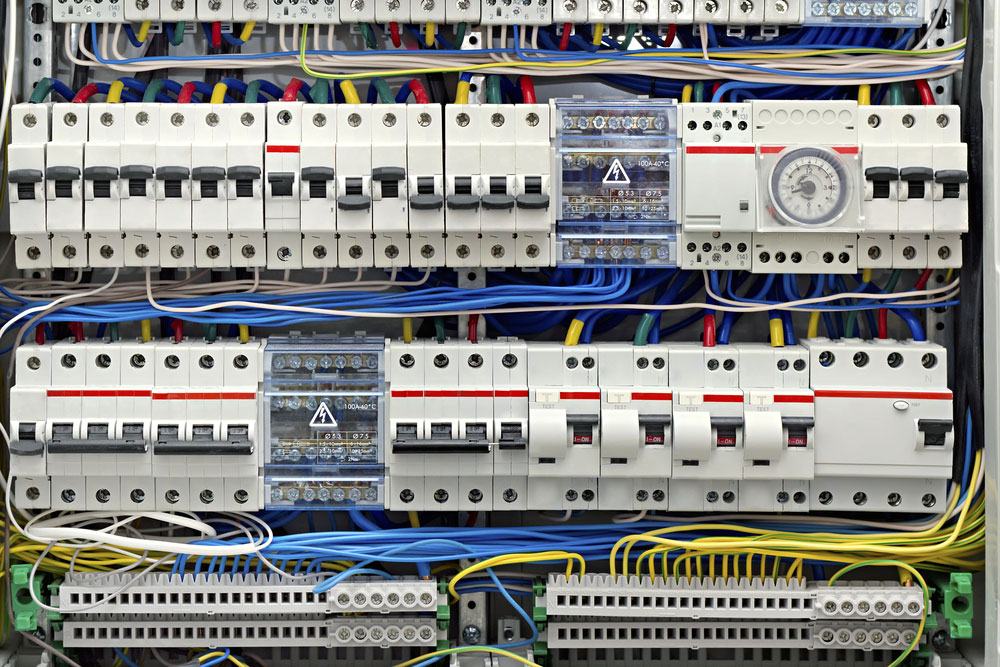

Caption: Multiple Box Builds

Source: https://www.carrmfg.com/

The application of box build assemblies

A box build is a specially designed product that you can use in many different ways. It can be a power circuit, a control unit, or other electrical equipment that needs a covering. Thus, it is hard to plan the physical design because the applications are always changing, so many customized designs are available.

Unlike traditional cable assemblies, these can be physical box harnesses, with only a few cables connected and no outside protection. Hence, these assemblies are very efficient when protecting against oil, climate, physical stress, abrasion, or movement from place to place. Moreover, unlike standard wire assemblies, the box helps in holding the whole assembly together securely. Thus, moving applications to different areas makes it easier and safer.

Among the most common parts of a box build is a data cable. The ways the data cable boxes are put together are very different from one another. Such data cable assemblies are often placed in big skyscrapers, hotels, residence or office buildings, and even some bigger homes. These groups can be very small or so big that they look like walk-in closets. Hence, the larger the place, the bigger the box built.

Sub Assembly Components for Box-Builds

These boxes refer to the PCB assembly connecting physical parts and the electromagnetic system with pneumatics.

Printed Circuit Boards (PCBs)

Printed circuit boards, or PCBs, are used in many electronic devices today. They can be as simple as single or double layers for systems like a TV remote or as complicated as 60 or more layers for something like a supercomputer or server. In contrast to conventional circuits, they have many advantages, such as being small and light, working more reliably, being easier to maintain, and costing less to make.

Customized Wire Assemblies

Inside a box build, the cables ensure electrical signals go to the right parts and sub-assembly. And the wires must be built, designed, and put in place in the right way so they can handle the environmental conditions and load without getting damaged. Expert manufacturers can make custom wire assemblies for projects like RF Cables, power cables, ethernet cable assemblies, etc.

DIN Rails

DIN rails or mounting rails are the parts in a box build to which other electrical parts are attached. They are often available in circuit breakers and control boxes for industrial equipment.

Power Supplies

The power supply gives the components in a box the electricity they need to work. It changes the voltage, current, and frequency of the electricity coming through the power source (like an outlet, battery, or generator) to what the assembly needs.

Programmable Logic Controllers (PLCs)

Programmable logic controllers (PLCs) keep track of data and ensure that larger and more complicated electrical devices and assemblies work as they should. These solid computers look at the data that comes in, goes out of the system, and use that data to trigger outcomes based on parameters that have already been set.

Pneumatics

Some electrical systems have pneumatics built into them. You can use pneumatic components like pistons, rotary tables, and linear slidings to turn air pressure into linear or rotary movement. Some other pneumatic parts are valves, switches, tubing, solenoids, and air regulators.

Relays

A relay is an electromechanical part that uses electromagnetism and a low signal voltage to turn a high voltage on or off while maintaining the voltage level electrically separate. You can also use two or more relays together to do Boolean functions. There are time delay relays that only let systems turn on and off after a certain time.

Safety Components

Safety should be one of the most important things to consider when making a box build. Sensors, light curtains, and switches are all safety parts that can help stop accidents or damage to equipment by slowing down or stopping function when needed.

Box-Build Designing Goals

One of the hardest things about making a box build is striking a solution between the product’s design and ways to manufacture it. Even though some designs meet the requirements, they might not be easier to develop. It can cause the product assembling costs and quality to go down.

On the other hand, some designs could be easy to make. However, they don’t meet the functional and design goals. Thus, in the ideal case, the design should have every wanted feature and be possible and cheap to make. The manufacturer needs to be involved in the first design talks to reach this goal. Their ideas and opinions help determine which patterns and parts will work.

Box-Build Manufacturing Process

The box-build manufacturing process can differ depending on the complexity of the product or part and the project’s needs. However, the basic manufacturing process is the same for all types, and it includes,

- Getting all cables and wires ready by cutting, removing insulation, crimping, and naming them

- Making and then testing the cable harness, individual wires, and other electromechanical parts and subassemblies

- Putting the system together from scratch, which includes putting in parts and finishing wiring

- Inspecting and testing the assembly after the set period

- Placing labels on all the necessary parts and subassemblies so that you can check and fix them in the future

- Implementing the software needed for the assembling

- Performing factory acceptance testing on the whole product.

Caption: Electrical Box Build with fuses

Things to Consider for Box Build Assembly Process

This step is critical to ensure the safety and success of the process before the actual work. Some important material includes schematics, sample units, wire run lists, and so on.

Bill of materials

Bill of material is an important part of the box assembly. It is since through the BOM, the electronic manufacturing services or EMS will know the components for the process. Each bill item has a purpose, specific cost, and procurement method. Moreover, it also lists the part description, manufacturer, packaging type, reference designator, number of items, and product code. Hence, as you create a comprehensive BOM, it will reduce the EMS provider’s distress.

3D CAD model

To better understand the result, you need a 3D CAD model. There are various CAD programs available, including free drawing viewers and the ability to turn your drawings into building plans. However, as you make the layout 3D models, it must include all the necessary components. That way, a 3D CAD tool can speed up building a box.

Sample prototype

To prepare a secure box build, you will need a finished product assembly, especially if you don’t have any other sources of information. Hence, making a rough prototype can help create multiple copies of an assembly. Moreover, an experienced electrical engineer can create a duplicate of a full box build even with a little bit of information.

Test protocols

During box build assembly, knowing the types of tests an EMS provider has to carry on is significant. Some testing includes acceptance tests done at the factory, functionality tests, and visual inspection. Thus, when putting together a box, an experienced EMS will help you achieve productivity and safety.

Design Drawing

Another crucial part of the box build assembly is the drawing. It tells the electronic systems’ functionality, components, and the manufacturing process it will go through. Hence, the manufacturer will figure out what the drawing means and find any possible flaws. He can do it by either cross-checking the drawing or looking for problems in the prototype.

What Are the Most Common Issues with Box Build Assemblies?

As you are going in for the manufacturing process of any electromechanical assembly, there is certain information that you should know.

The Source of the Enclosure

When choosing a box build, you need to source an enclosure with the suitable price, durability, texture, and other material attributes for your application. Here, custom or off-the-shelf enclosures are the two main options available.

Off-the-shelf alternatives feature reduced prices and minimum orders but limit custom capabilities. However, you must test the prepackaged box builds for heavy use. On the other hand, custom box builds require less testing because they’re tailored for your specific needs, but they’re more expensive and take longer to the source.

Poor Documentation

Whether choosing an off-the-shelf option or developing your assembly, verify that the documentation is proper. A written record of all CAD designs, versions, and BOMs can help with problem-solving. Moreover, documenting the box’s components and assembling processes simplifies maintenance and repair.

Inadequate Testing Procedures

Proper box build assembly testing comprises an enclosure and PCB evaluation (PCBs). Stress screening and soak testing are standard ways to test a box’s suitability for its surroundings.

Soak testing measures software performance under an intensive data load. In comparison, stress screening pushes the system to its point of collapse to find flaws. These tests, plus PCB-specific testing like border scans, in-circuit tests, and flying probes, ensure your product’s real application viability.

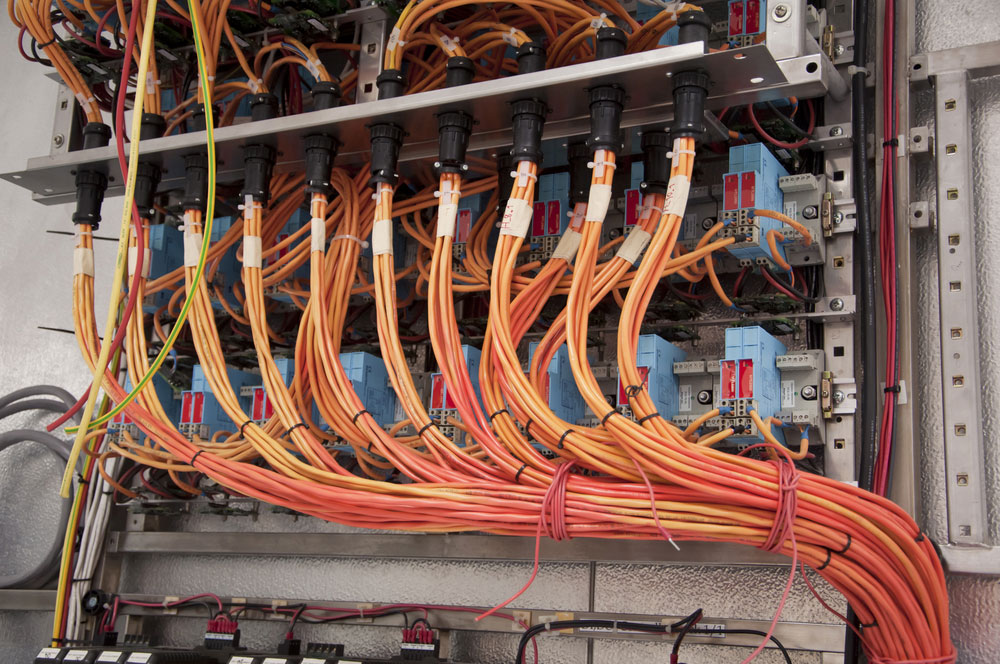

Caption: Control Panel Box Build

Benefits of Good Box Build Assembly Services

The users can get a lot by hiring a good box build Assembly service.

Reduction in production costs

Production costs go down because manufacturers can pay for less of the connectors, wires, and tie wraps you would buy if you bought them in small quantities. Moreover, a good build assembly service ensures that its workers know how to test and install different build boxes. When you hire EMS, they can easily switch between models. Experience helps people do better work and get more done.

Quality

Services that build and assemble PCB boxes should ensure they do the job right. They do a good job at what they do. For higher assembly processes, it’s important to use a box build assembling that tests the systems for best usage.

Supply chain simplification

Supply chain simplification is what skilled box build and assembly services do to simplify the supply chain. These services offer knowledge by telling you how can tell you what to do to make your design work better. Moreover, they will make your supply chain less complicated because they are in charge of making or buying all the components.

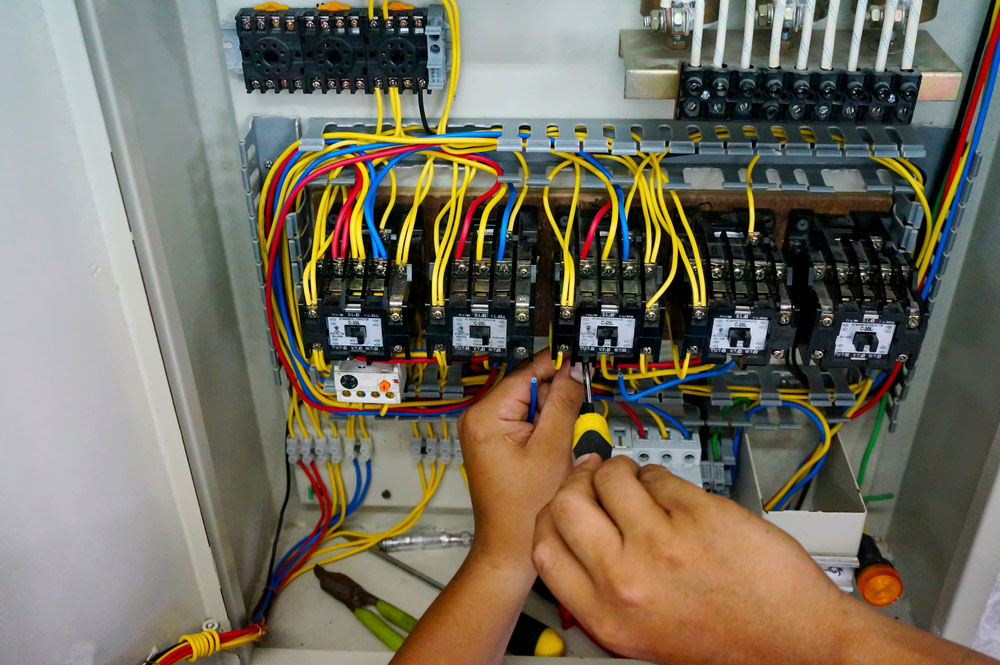

Caption: Contractor working on Box Build

Conclusion

Box build secures the components for their long-lasting safety. We offer wiring harnesses and box building experts, ensuring your connection is made with attention to detail. To avail of our services, contact us now.