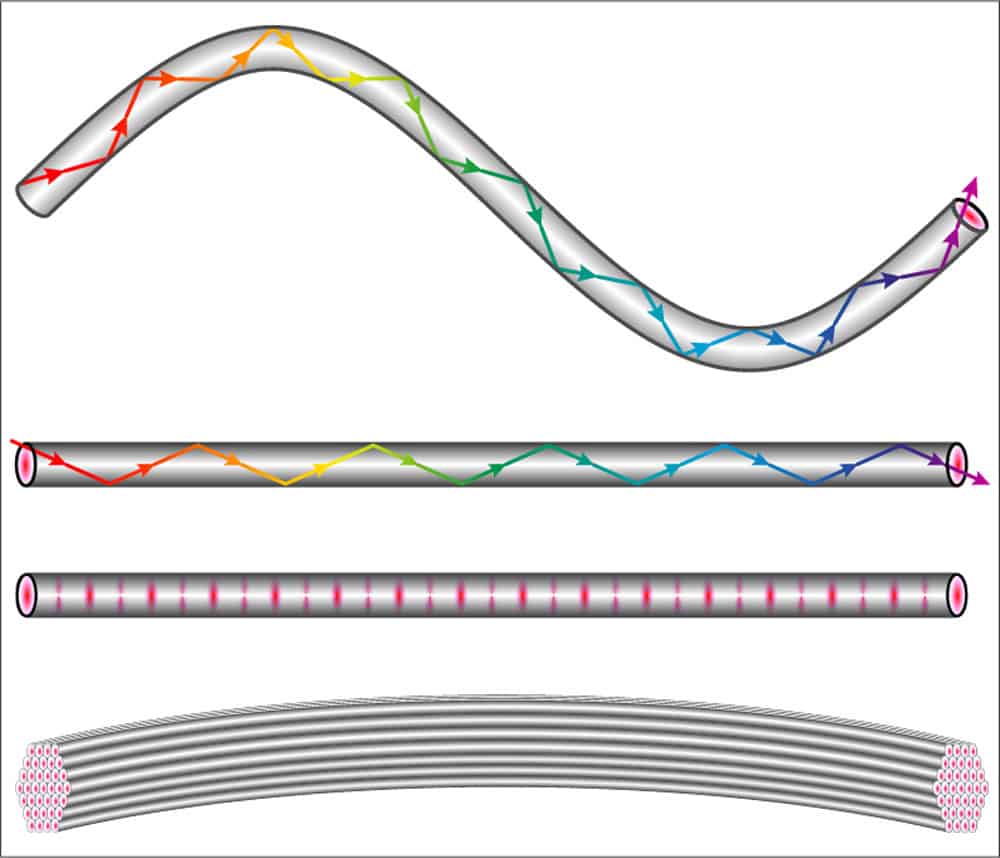

While you may think 100% of the liquid passes through, some of it will remain on the tube’s insides. In the same way, when light signals reflect inside the cable, they bounce from one place to the other. This constant bouncing makes the signal lose a bit of strength each time it passes by and comes back. Learn about it and handle an optical loss like a master with this guide.

Table of Contents

- Optical loss – Meaning and Types

- Optical loss – Main Causes

- Total link loss – How to Calculate it

- How to Reduce Optical Loss

- Conclusion

Optical loss – Meaning and Types

Understanding what optical loss is, is vital for both optic fiber users and operators. It will help both parties to know how the network works and how to make the most of it. These are the two main types of optical loss possible.

Insertion loss

Insertion loss refers to the light attenuation present in fiber optic when the signal is transmitted from A to B. However, insertion loss occurs for many reasons.

First, it derives from fiber splits, cuts, and bends. Whether they may be minor or major misalignments, any fissure translates into a minimal loss of signal. Nonetheless, the attenuation level, in this case, is lower than 0.1dB.

Second, IL also occurs due to fiber optic over-extension amidst pulling, cracks, and even crush and impact damage. Despite being very small cracks at first, these represent one of the worst nightmares for optic fiber operators. The reason is that these kinds of cracks are the hardest to find throughout the entire connection.

Third, insertion loss may occur due to the distance the cable travels from A to B while installing the cables. The longer the distance, the higher the insertion loss.

Return loss

On the contrary, return loss refers to the loss of signal power when going back from point B to A. When the impedance is too high, the network simply stops working, shutting down the signal transmission. To avoid most of the return loss, operators know they should always use angled ferrules when working with optical fiber. Using high-quality cables, connectors, and splitters, ensures the proper functioning of the Fiber to the Home (FTTH) network.

In addition, operators must always consider return loss when planning and installing a network in order to fix issues beforehand. Testing everything before, during, and after the installation will save you from future troubles.

Optical loss – Main Causes

As previously stated, there are many causes for optical loss. However, these are the main four causes, you’ll learn about in-depth.

Gap

If there is a gap between fibers, optical loss is bound to happen due to light refraction in the air. These gaps often occur when operators perform fusion splicing in the wrong way, failing to properly fuse both fibers ends.

Poor core alignment

When fiber optic cables are joined together with a new cable, a perfectly aligned connection must happen to avoid any malfunction. Making a poor alignment of the core fibers will translate into minor to major signal loss.

Reflection

This happens when the fiber end is not properly cleaned and polished. When fiber optic cables have rough edges, the light signal passing through them will scatter and lose. In addition, dirt also creates a proper scenario for optical loss due to blocking light, cutting the signal.

Axial run-out

Axial run-out refers to the excess angle in the splits and connections done during the installation. That’s why it’s important to keep all cuts as smooth and straight as possible. This will avoid splits and fissures in the fiber in the long run.

Total link loss – How to Calculate it

As a way to avoid any kind of optical loss, there are some calculations you can do. Performing an optical time-domain reflectometer allows you to estimate all the variables needed to solve optical loss-related issues. To calculate the total link loss, it’s crucial to know the number of connectors and splices, and the fiber distance used.

Multiply the fiber length by the fiber attenuation level. Then multiply the splice loss factor by the number of splices. Also, multiply the connector loss factor by the number of connectors. Then sum all these factors to the safety margin factor, and you’re set.

How to Reduce Optical Loss

In order to reduce optical loss to the minimum, there are some must-follow tips that will help both users and operators to make fiber networks work properly.

Avoid any bends

Avoid all kinds of tight bends that may cause light to split through the fiber. To minimize this and stop it from happening, keep the core radius as large as possible. This will allow it some room to refract.

Keep it all clean

Keep everything clean, before, during, and after testing the network. This includes everything from cables to connector ferrules. Always use the right equipment and components to ensure the proper functioning of the network.

Choose wisely

Think really hard about it and decide your budget. Whether you invest more money in a power loss budget or cable inventory, the final decision is yours. However, always remember that working with low-quality fiber optic cables will translate to more and recurrent problems in the future.

Keep it straight

It’s vital to know this beforehand, particularly during installation. To avoid fiber stress due to pulling and tightening the fiber, always remember to push the cable instead of pulling. However, if pulling is mandatory, do it softly and don’t go over the cable’s max tensile load to avoid trouble.

Think ahead

In order to make the most out of your budget and ensure minor optical loss at the same time, thinking ahead is a must. Plan the network ahead of time, minimize how many connections or splices you’ll need to make it work.

Conclusion

Optical loss is easy to occur; however, it is also easy to avoid when done the correct way. Follow the previously-given tips and enjoy fiber-optic connection in all its glory. If you look for information or need guidance on it, we can help you with all kinds of cable assemblies.