The main thing that builds or breaks a system in every electrical system is the components you choose. Thus, you have to make the component purchasing decision the moment you start working on the designs. Here, you will see that multiple wire harness components make assembling a successful task. Also, in the process of choosing the electrical components, you must consider a lot.

Table of Contents

- Wire Harness Components

- Qualities to Look for in Wire Harness Components

- Considerations When Choosing Wire Harness Components

- What Conditions Will Your Equipment Need to Endure?

- Conclusion

Wire Harness Components

When choosing a wire harness, it’s essential to keep in mind the capacities of each component. It ensures that the power supply is giving appropriate energy to the devices and safety is intact.

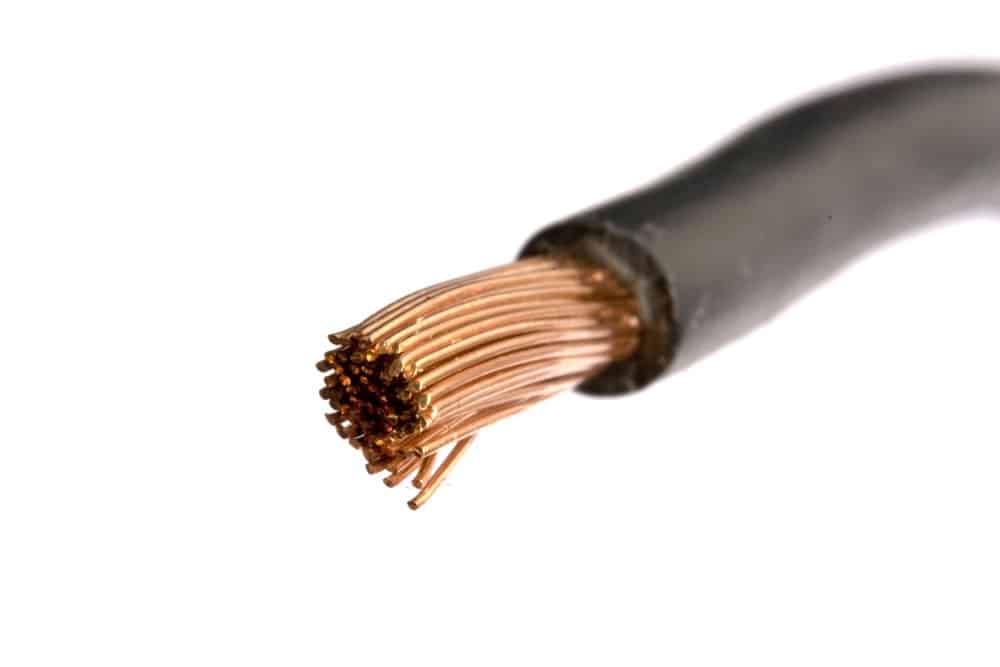

Wire

The wire is the critical component of any wire harness since it carries the flow of charges that powers a device. Here, the capacity of a wire has to handle the voltage it has to transmit. For that, you can buy a cable whose threshold is greater than the current value you will pass through it.

Moreover, most cables are made up of copper conductors, which are cheaper and ensure a good current flow. Also, the wire has a special insulation coating so that it does not give you an electric shock while working around them.

Caption: Coils of Electric Wires

Connectors

Wire connectors are of several types to connect different types of cables. While they are usually plastic, they can be made from a variety of elements, including metal. If you want to combine the wires or any other component to make an electrical product, you need to place connector terminals on the front. That way, you will make sure a stable current flows in the system.

Common types of connectors are crimp-type connectors and multi-pin connector contact.

Caption: Typical RCA Connectors

Fuses

Fuses prevent the excess of power from damaging the component present on the other side of the connection. In case of a power surge, the fuse blows, and it has very little tolerance for high currents. Thus, as the current, higher than its rating, passes through it, activates the fuse’s internal mechanism and breaks the overall circuit’s connection.

Different wire harnessing has to use fuses of different thresholds, according to the need. They are typically rated for 32 volts or less and vary depending on the ampere rating and safety standards.

Caption: Man Turning off the fuse from a circuit board

Grommets

Grommets are insulators that prevent moisture from getting to the connector. Moreover, you can attach the grommet on the terminal side or part of the connector.

Outer coverings/Insulators:

Outer coverings or insulators provide a degree of protection from cuts, abrasion, environmental factors, and electrical shock. Also, the insulation can be made of various materials such as nylon or polyolefin. It depends on the type of wire you are getting for the system.

Caption: Insulated Electric Wire

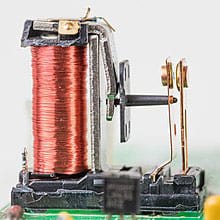

Relays

Just like the fuse, some systems that are high amperage need to have relays installed in them. You can choose a relay if you want to switch the current in a control circuit. Also, it is not a power-consuming component, and thus you can use it in small motors and solenoids.

Caption: A Simple relay mechanism without casing

Strain Relief

Usually, the manufacturer adds strain relief to the outside of the connector, and it helps prevent the pulling force that makes the connection with the power source unreliable. Thus, by using strain relief, you can strengthen the relationship on both ends of the wire.

Also, you can add a strain relief at an outer bend radius, which may put undue force on the wire and the terminal inside of the connector.

Terminals

You may have seen the ending of the electrical wires usually secured by metal components. These components are known as terminals. With their help, you can insert the wire or connect it to any wire slot equipment.

Cable Ties

Cable ties and clamps help the cable assemblies to be in one direction. If you don’t use a clamp in complex connection systems, the chances are that the inner wires tangle with each other, increasing the overall resistance of a cable. Moreover, you can also attach a tie to twisted cables at specific points to minimize the movement.

Caption: Electric wire tied with cable ties

Locks

Just like strain relief, a lock also prevents the wire from pulling out of the connector. That way, you can correctly insert the cable terminal into the connector, preventing a bad connection, and now you are ready to attach it to other equipment.

Qualities to Look for in Wire Harness Components

While choosing a wire harness component, some of the essential component qualities that you can look into are:

- Type of wire

- Outer sheath, conductor, and insulation material

- Voltage and current specifications

- Organization of the assembly

- Environmental capabilities

- Safety certification

Caption: Components for electric systems

Considerations When Choosing Wire Harness Components

We should keep two things in mind in the wiring harness manufacturing process.

In which industry will you use a wire harness?

Many industries use wiring harnesses to cut down the labor of manufacturing while working on large projects. For example, there is a comprehensive application of cable harnesses for military and robotics manufacturing.

So, you cannot use the same circuit design for a car as you use for a ventilator or airplane. Thus, you need to follow different patterns for different industries. Here, a plan may require several wires to connect, or only one wire could suffice.

Caption: Man working on High electrical Pole

What Conditions Will Your Equipment Need to Endure?

The environmental conditions where you will deploy the wire harness determine the components you will use while developing a system. Here, you need to consider these two main questions.

- Will you install the cable harness indoors, or will you expose it to the outdoor environment?

- Does the cable have to pass through areas with moisture in the air, or are chemicals flowing around it?

You might have a few more questions to ask. Still, working in the designing stage will save you a lot of money and resources in the future. Hence, if you choose an OEM (which is known as the Original Equipment Manufacturer) company at this stage, you will get knowledge and complete guidance on how to select the required components.

Conclusion

In conclusion, every specification of the design needs to be addressed upfront before manufacturing can begin. It is always a best practice to bring up all the details with your manufacturer to help determine what the proper cable assembly will best suit your end product’s needs. Here at Cloom, we can find the most suitable wire harness component for the cable connection. So, for any query, contact us.